Be the first to know.

Get our 3D Printing & Digital Manufacturing weekly email digest.

3D Printing & Digital Manufacturing

Engineers Wiki. Most Asked Questions.

Comprehensive Guide

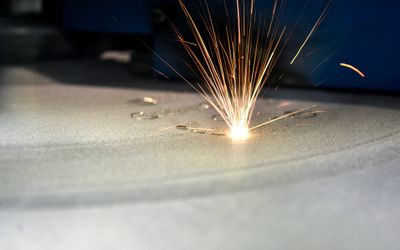

An engineer’s guide to understanding the state of the art in metal 3D Printing

Different Filament Types: A Technical Guide for Engineers

By Benedict O'Neill.

12 minutes read.

Vapor Smoothing 3D Printed Parts

12 minutes read.

View more

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

View more