Computational Advances in Footwear Design

From the experts at CDFAM Computational Design Symposium

This article was first published on

cdfam.comThe Future of Footwear is Computational

Footwear design sits at the intersection of industrial complexity and user-specific performance. Each product must balance structural function, fit, aesthetics, and branding—across multiple sizes and manufacturing constraints. As performance demands increase and supply chains evolve, computational design is emerging as a critical enabler for innovation in the footwear industry.

Algorithmic modeling, generative design, and advanced simulation are now being integrated directly into tooling, prototyping, and customization workflows. Engineers and designers are using these methods not only to define geometry, but to automate variation, validate performance, and prepare data-rich outputs for scalable production. This convergence of design, engineering, and manufacturing is making computational tools indispensable for footwear development.

These themes will be explored in depth by a group of featured presenters at CDFAM Amsterdam 2025, each bringing a different perspective on how computational methods are being applied to footwear—from algorithmic upper design and additive-ready tooling to the use of advanced geometry processing in customization and performance modeling.

What’s Next in Computational Footwear Design

Maia Zheliazkova – On

LightSpray™: A New High-Performance Upper Technology

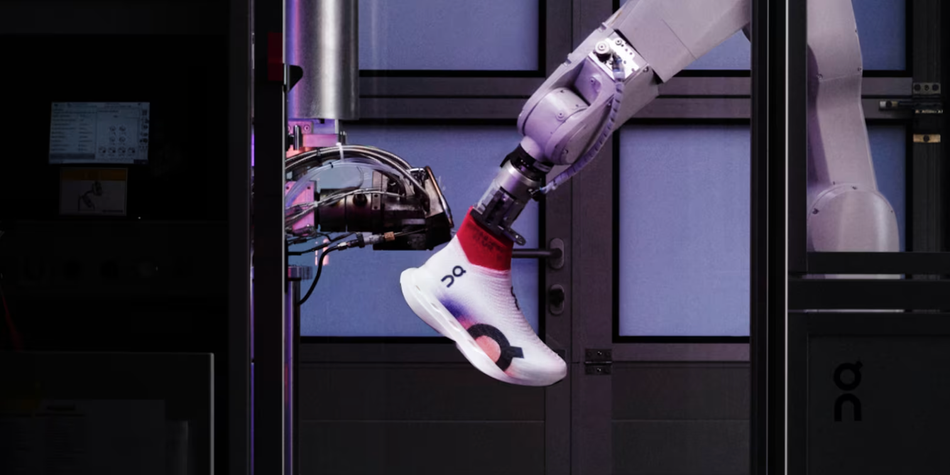

On’s LightSpray™ process uses robotic spray deposition to create seamless, ultralight shoe uppers in a single step. Maia’s presentation explores how computational design and robotic programming combine to eliminate traditional pattern making, reduce waste, and enable rapid, iterative development.René Medel – Framas

Injecting AM into Shoes

René shares how additive manufacturing is being integrated into traditional footwear tooling. His talk focuses on generative workflows that support rapid design iteration, reduce tooling complexity, and maintain compatibility with high-volume production—bridging digital flexibility with physical constraints.Math Whittaker – New Balance

Beyond Surfaces: Applying Intrinsic Geometry Processing in Art and Design

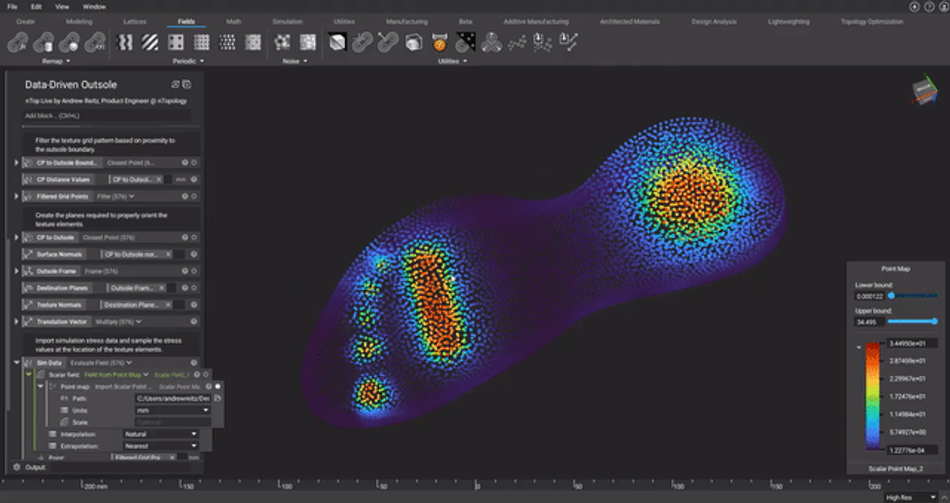

Math will present how intrinsic geometry processing—techniques that operate independently of spatial embedding—can be applied to footwear design. Drawing from his work at New Balance and his background in architecture and computational art, the talk explores how vector fields, reaction-diffusion systems, and mathematical surface logic are informing new approaches to design and customization.

Computational Methods in Practice

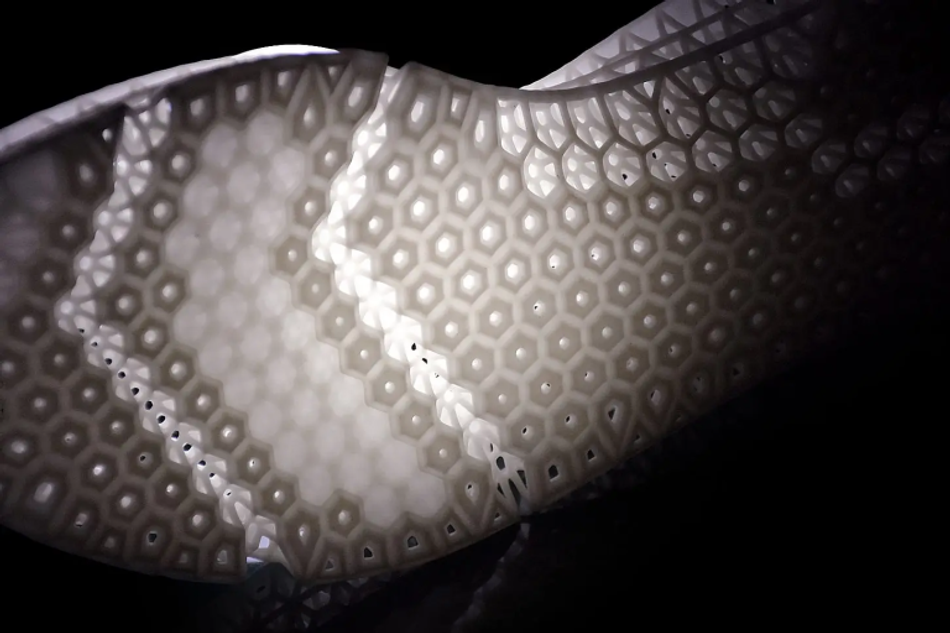

The value of computational design in footwear lies in its scalability and adaptability. Parametric control allows geometry to scale across size ranges while maintaining key performance features. Lattice structures and surface logic can be tuned for cushioning, airflow, and flexibility. Algorithms encode the logic of performance—and when integrated with additive or hybrid manufacturing, these designs can move directly to production without translation or rework.

Across the industry, these methods are beginning to define not just how footwear looks, but how it performs, how it's made, and how it fits diverse users.

Lessons from Earlier Pioneers

The evolution of computational footwear has been shaped by contributors from both industry and research:

Natalie Alima (BioLab + Adidas) explored biological growth models and robotic feedback in shoe design.

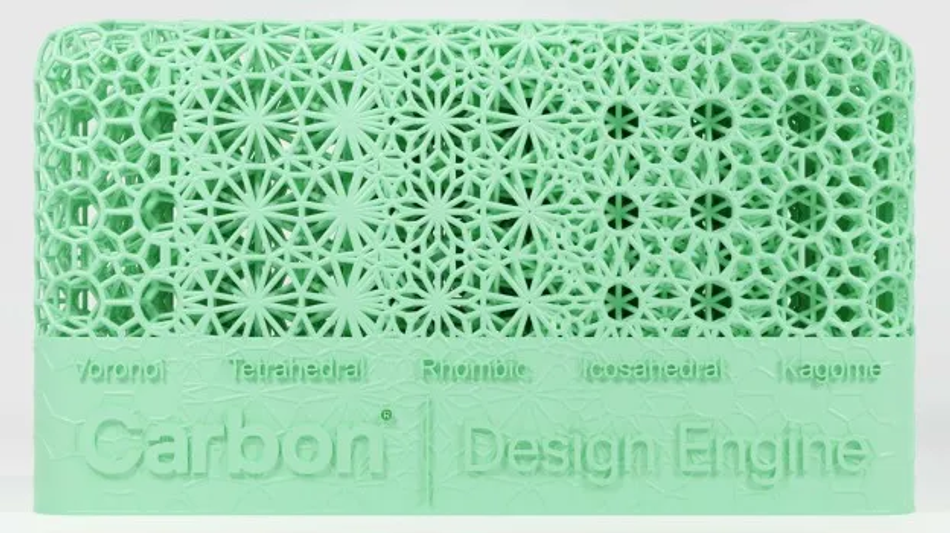

Hardik Kabaria (Carbon) demonstrated how machine learning was used to inverse-engineer FutureCraft midsoles for Adidas.

Ronnie Parsons (Mode Lab) discussed Nike’s early experiments in connecting generative design to material science and advanced manufacturing.

Jesus Marini Parissi (MoonrabbitX)

Ruiqi Chen & Andrew Sink (Carbon) presented scalable systems for biomechanically adaptive design and mass customization.

Software Tools Enabling the Shift

Many of the breakthroughs in computational footwear rely on a new generation of digital tools:

nTop – Implicit modeling for lattice structures and simulation-ready design.

Carbon – Parametric performance design linked directly to additive manufacturing.

ShapeDiver – Web-based customization interfaces for parametric models.

Spherene – Lightweight shell and lattice structures optimized for performance.

Altair – Simulation, optimization, and multi-physics tools for early-stage concept development.

Rhino + Grasshopper – Still foundational for parametric workflows across prototyping and production.

Why Footwear Leads in Computational Manufacturing

Few products demand as much performance tuning, personalization, and aesthetic specificity as footwear. And few industries face such intense pressure to innovate while scaling. That makes footwear an ideal case for computational design: a domain where geometry, data, and fabrication intersect.

Today, these tools are being used not just to shape individual parts—but to rethink the workflows, infrastructure, and logic that connect design to production.

See It Firsthand

These conversations will come together at CDFAM Amsterdam 2025, where engineers, designers, and software developers working across footwear and digital manufacturing will share their work. The single-track format encourages exchange across disciplines—whether you're exploring additive production, simulation-driven workflows, or AI-accelerated design tools.

Register at https://cdfam.com/register/ to learn more, ask questions, and connect with the people building the future of computational design.