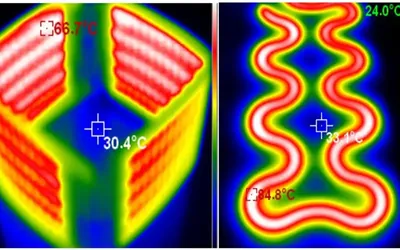

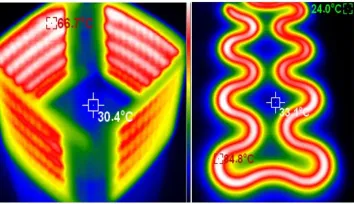

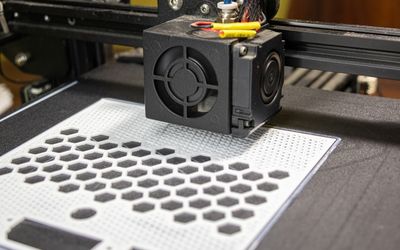

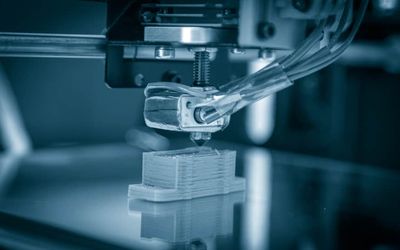

Subterranean drone tackling food security wins The High-Temperature Carbon-Fiber 3D Printing Challenge

Based on the 'Crover Effect' for locomotion in granular media, the CROVER robot is able to move through bulk solids and powders. The team wins $25,000 of manufacturing support from Mitsubishi Chemical Advanced Materials to take their design to the next level.