Top 5 benefits of 3D printing in higher education

What technologies have had the biggest positive impact on education at every level and across every subject? Projectors, printers, laptops, and personal computers? We believe that in a decade's time, anyone asking that question will not hesitate to add 3D printers to the list.

If you are a professor or an administrator at a higher-learning institution, you absolutely need to be aware of the benefits that 3D printers can have for your students and your faculty. This article will take you through some of the ways that 3D printing can disrupt and bring positive change to the way you operate.

3D printers are easier to use and more affordable than ever

If you previously dismissed 3D printing as prohibitively expensive or too limited to be useful, now is the time to reconsider. In the last decade, 3D printing has made major advances that have brought the price of the technology down while also making them more capable and reliable than ever.

These advances, particularly when it comes to FFF (filament-based) and SLA (resin-based) printers, mean that prices have gotten so low that you can outfit a whole lab with ready-to-use printers for less than a single printer would have cost 10 years ago. In some cases, a single printer can cost less than the price of one of your students’ textbooks.

It’s also not just the financial barriers that have dropped. The knowledge requirements have decreased significantly too. Gone are the days where operating a 3D printer required almost as much expertise as it took to design and build one in the first place.

Today, anyone who’s capable of following instructions and performing some basic troubleshooting can operate a printer. Meaning that your students can use them directly without needing a trained professional to hold their hand through the whole process. And because printer reliability is higher than ever, the ongoing maintenance requirements are greatly reduced.

To make the process of adopting 3D printing as easy as possible, Ultimaker includes access to the Ultimaker Academy with every Ultimaker printer purchase. Users of the Ultimaker Academy get access to a library of expertly crafted online courses that help guide first-time users in how to operate our machines. Meaning that if you buy an Ultimaker, both your staff and your students will have the knowledge they need to be able to confidently use them in the classroom.

3D printing is the most versatile form of manufacturing imaginable

When using a 3D printer, you have the option of printing with an incredible selection of materials. Not just different kinds of plastics, but also metal, carbon fiber-filled filaments, and more. All of them have their own unique mix of properties meaning that if you need an object that is flexible, or rigid, heat-resistant, or chemical-resistant, there are options available.

The reason that this is such a benefit is that the applications of 3D printing are endless. Everyone who knows what a 3D printer does can imagine how it could be useful for engineering or design. But there are credible and demonstrable ways that 3D printing can help students studying biology, geography, mathematics, and more. 3D printing is the ultimate cross-disciplinary technology and the only limitation on the ways it can be used are the imagination of your staff and your students.

Take for example the Health Design Lab at Thomas Jefferson University that uses 3D printers to aid clinicians, students, and patients. They realized they could turn patient CAT scans and MRIs into 3D printed objects so that a surgeon is able to hold and examine an anatomical model of the patient they’re about to operate on.

Keep your students engaged and excited with 3D printing

There is a special look that someone gets when they first see a 3D printer in action. If you choose to adopt 3D printing, it’s a look you’ll become very familiar with as it will be on the faces of all your students when they get to use a printer for the first time.

3D printing can transform a subject from theory, and words on a page, to something tangible that can be touched and engaged with. Once you give your students that power, they will shock you with the amazing things they end up creating, and the enthusiasm they do it with.

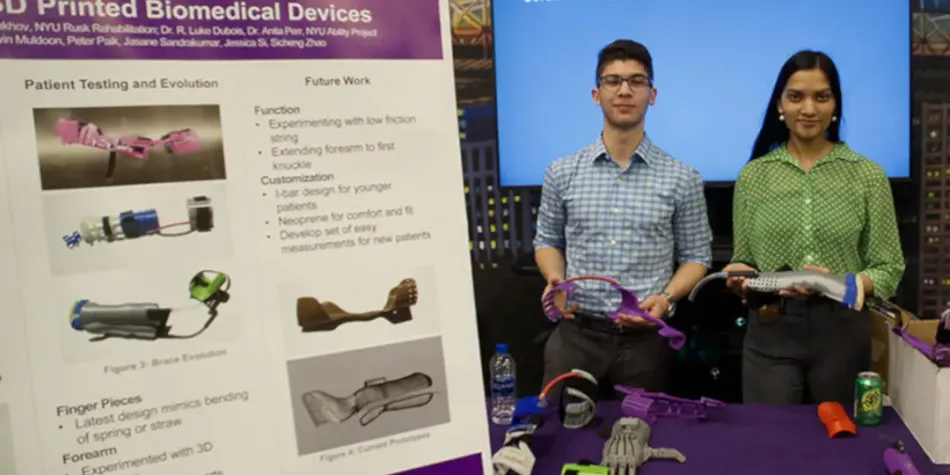

A fitting example of how this enthusiasm can be channeled in a positive way is the team at NYU Tandon researching 3D printed orthopedics. Their goal is to design and create customized, low-cost 3D printed orthotic braces for children with degenerative muscular disorders like cerebral palsy. Since the team is a vertically integrated project (VIP) the students on it can gain course credit towards their degree while contributing to a long-term sustainable research project.

3D printing can enable new levels of innovation

When you have a versatile technology and you put it in the hands of extremely motivated users, you have a perfect recipe for innovation.

3D printing has the potential to enable a broad range of activities including groundbreaking curriculum, interdisciplinary collaboration, and advanced research projects. Many startups have even sprung up on campus thanks to the opportunities provided by 3D printing technology.

One company that has taken that opportunity and ran with it is PROTECT3D. Founded by former Duke University Football players, they make custom athletic equipment by scanning the anatomy of a player and using those scans to design and print protective gear.

What makes PROTECT3D such an inspiring story is that the origin of the company came when Duke Quarterback Daniel Jones fractured his clavicle and had to undergo corrective surgery. Kevin Gehsmann and Clark Bulleit were his teammates at the time and they saw the opportunity of 3D printing and were able to design and print a pad that protected his collarbone and allowed him to get back on the field in just 3 weeks.

Kevin and Clark were able to identify a problem, create an innovative solution, and then use that solution to start a company that has gone on to win a $50,000 prize from the NFL 1st & Future Pitch Competition. As well as getting to work with numerous professional athletic teams and organizations.

PROTECT3D and companies like it are proof that when introduced early, 3D printing can enable students to make a real impact both on campus, and off it.

Resilience

The COVID-19 pandemic has highlighted an aspect of 3D printing technology that was previously undervalued. It is remarkably resistant to major systemic disruptions.

3D printers don’t require a large crew of personnel to run. Desktop printers are compact and flexible in where they can be placed. And they don’t have any complicated installation requirements. Essentially, all you need is a power supply and some material to print with. This means that many institutions with existing 3D printing capabilities were able to keep their printers up and running throughout the pandemic. Printers could be moved into individual classrooms to help with social-distancing requirements. Prints could be sent to printers or printer operators remotely and then picked up or forwarded on after completion. Students were even able to take printers home in some cases.

So, if you are considering setting up a 3D printing lab, or even just adding a printer or two to your makerspace or classroom, rest easy knowing that as long as they are properly maintained and responsibly operated, your new printers will keep printing in even the most turbulent of circumstances.

And, even when the world is not being threatened by a global pandemic, printers are versatile enough that they can be used as part of a mobile cart and wheeled to where they’re needed most. A fact that The University of California San Francisco has embraced with great success.

Hear what other educators have to say

There are more examples of how educators are using 3D printers in amazing ways than we could possibly fit into this article. Luckily, if you want more, we have a round table webinar where we talk to three prominent educators about how they have applied the versatility and accessibility of 3D printing.