Be the first to know.

Get our pcb weekly email digest.

Tagged with

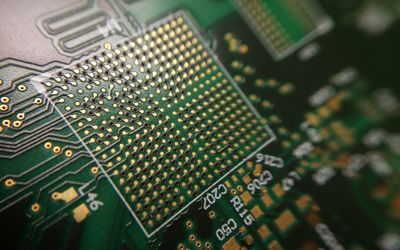

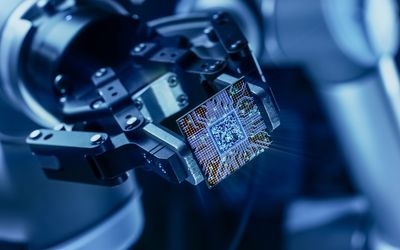

PCB

ORGANIZATIONS. SHAPING THE INDUSTRY.

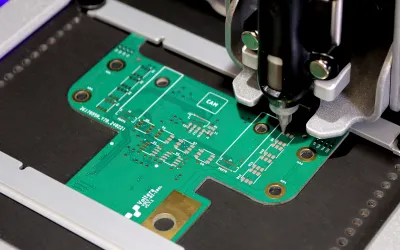

HQ NextPCB

Appliances, Electrical, and Electronics Manufacturing

HQ NextPCB specializes in reliable multilayer PCB manufacture and assembly ...

1 Post

AllSpice

Software Development

Hardware collaboration platform 🤖 Inspired by software development princip...

View more