Tagged with

displays

ORGANIZATIONS. SHAPING THE INDUSTRY.

Latest Posts

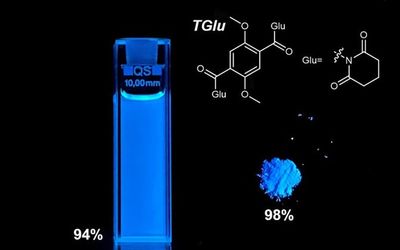

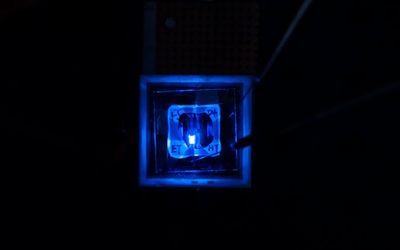

Displays, imaging and sensing: New blue fluorophore breaks efficiency records in both solids and solutions

Reaching 98% efficiency in a solid state and 94% in solution, the small fluorescent molecule's design could cut down development time and cost for future applications.

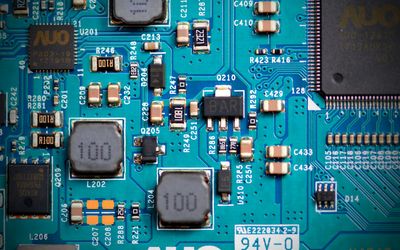

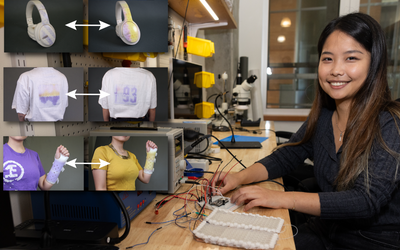

Bridging the Divide: Transitioning from Lab-scale to Industrial-scale Equipment in Printed Electronics Development

Transitioning from Lab-scale in Printed Electronics: Going from lab and pilot equipment to rotary screen printing. Learn about example applications in printed low-power displays for use in retail as well as cost-per unit calculation comparing flat-bed vs. rotary screen printing for mass production

Electronic shelf labels (ESL) are connected, low-power ‘e-paper’ display devices that can replace traditional paper labels and can display text, numbers, icons, lines, barcodes and pictures. They enable retailers to automatically update individual shelf price labels from a central point across multiple stores and branches—or in certain geographic locations—at the touch of a button.