Based in South Korea, Autocut is an automotive paint protection film (PPF) and tinted film solutions provider. It delivers software with 17000+ pattern data of paint protection films (PPF) and pre-cutting films for automotive aftermarket shops. Pre-cutting of the film based on the shapes of car parts is needed for productive PPF projects. With over 15 years of expertise, Autocut’s solutions are adopted in over 100 shops in South Korea.

Tagged with

digital manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

View more

Latest Posts

Unlike the traditional production, the on-demand and customized high-mix, low-volume manufacturing services of RPWORLD allows for the design flexibility that mass manufacturing cannot offer. Moreover, the process, tooling and materials being used for low-volume parts sometimes are not as certain as those of mass production parts. That’s why quality assurance is paramount at RPWORLD and it’s one of the core benefits for our customers.

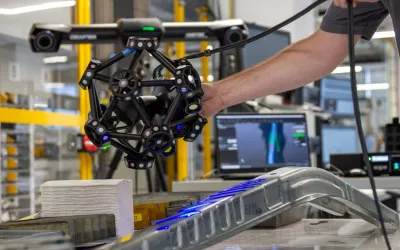

Following the example set by the FIA, M-Sport saw the need to introduce 3D scanning to control the body shell’s accuracy and ensure that the car met regulatory requirements. After all, winning performances often occur by pushing as close to the limit as practical while remaining compliant with regulations. 3D scanning proved to be the technology required to reach this balance.

When digitization meets connectivity, you enter the smart factory. As an essential part of the fourth industrial revolution (Industry 4.0), it aims to optimize smart manufacturing processes. The fully digitized manufacturing facility of the smart factory uses devices, sensors, machinery, and production systems to continuously collect and share data.

How Creaform Met the Need for Enhanced Accuracy, Versatility, and Efficiency of voestalpine Stahl GmbH

High-precision measurements, shorter surveying times and the rapid further processing of the data obtained convinced voestalpine Stahl.