BTO Production of Analytical Instrument

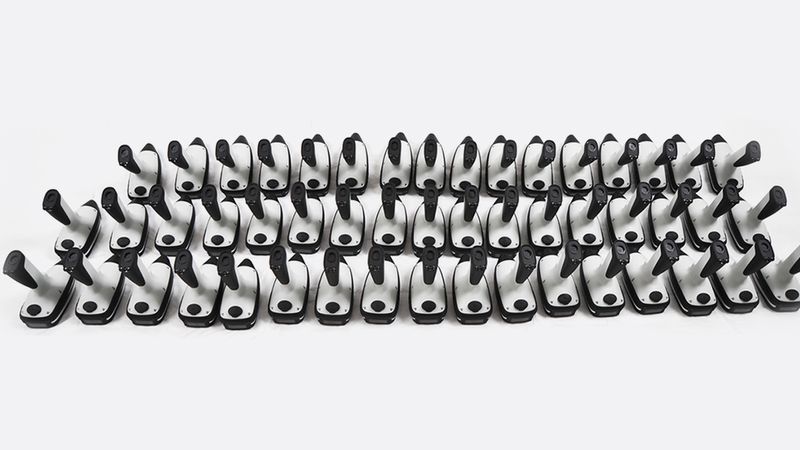

A company well-known for superior analytical instruments and laboratory equipment opted for RPWORLD to produce 100 units assembly parts of a Spectrometer per order, the total demand is 400 sets per year.

Project Background

A company well-known for superior analytical instruments and laboratory equipment opted for RPWORLD to produce 100 units assembly parts of a Spectrometer per order, the total demand is 400 sets per year.

RPWORLD Solutions

Processes Chosen

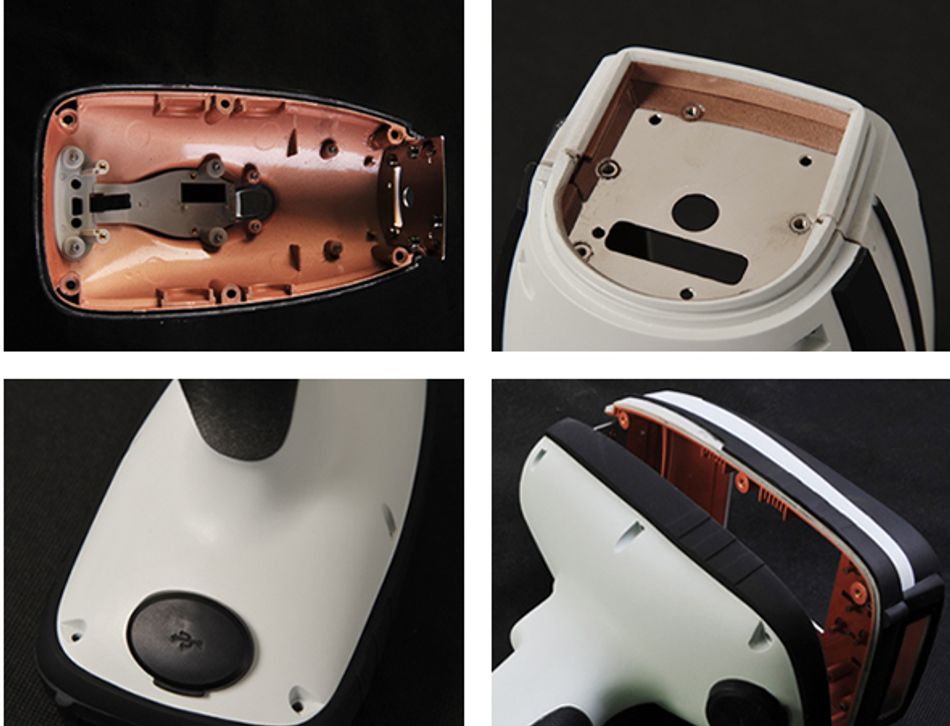

• After meticulous analysis and discussion, we chose vacuum casting combined with over-molding process, for the metal parts, we use CNC machining and sheet metal process.

• Internal copper painting for EMC.

Material Selection

• ABS performance Polyurethane Resin, PC,TPE

• Rubber to be over-molded

• Stainless steel, aluminum

Production Schedule

| • Rapid prototyping and testing | 7 days |

| • Silicon mold manufacturing and testing | 3 days |

| • 100 units replication by urethane casting | 15 days |

| • After-treatment by specialist | 5 days |

| • Total | 30 days |

Testimonials

The characteristics of RPWORLD are good quality, delivery on time, good technical knowledge of employees and fair prices. So RPWORLD became our preferred supplier for our new product development projects.