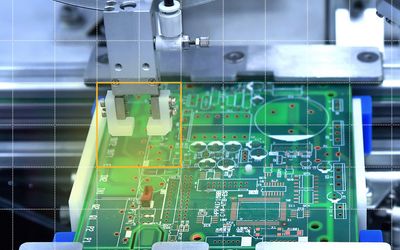

Join MVTec to explore how advanced machine vision software is revolutionizing semiconductor wafer inspection with live demos, not slides—boosting precision, quality, and efficiency.

Webinars

Latest Posts

webinar | JUN 05 - JUN 05, 2025

webinar | JAN 15, 2025

Join us for The Rise of Generative AI at the Edge: From Data Centers to Devices webinar on Wednesday, January 15th

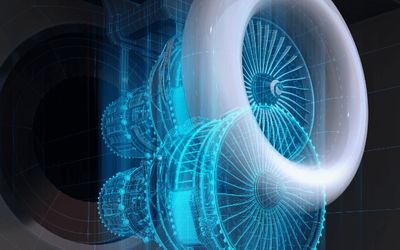

Missed The Webinar? Watch It On-Demand: Unlocking the Power of Digital Twins for Aerospace Manufacturing

Listen to industry experts from Quest Global discuss how digital twins are transforming aerospace and defense manufacturing by cutting design cycles, driving predictive maintenance, and improving manufacturing efficiency.

1