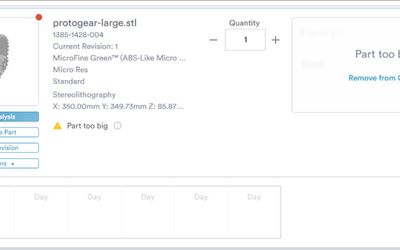

Slicing software has been around since the very beginning of 3D printing, with digital slicing of STL files being one of the key features of Chuck Hull’s first stereolithography system. However, in the time since, slicing software has evolved beyond its base functions of simply converting 3D object models into machine instructions.

Tagged with

3D Printing

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

View more

Latest Posts

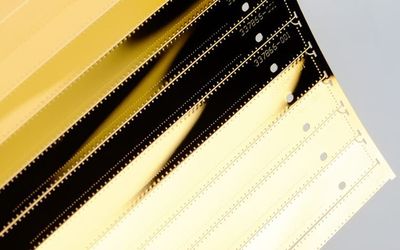

The making of micro-precision nozzle plates: 3D Printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming compared

Micro-fabricated nozzle plates are used in various industries, such as inkjet printing, medical devices, and flow control. Manufacturing these nozzle plates requires precision and accuracy to achieve the desired performance. Several production technologies can be used to manufacture micro-fabricated metal nozzle plates, such as 3D printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming. In this article, we will introduce these production technologies, and illustrate how to find your preferred process for the production of micro-fabricated nozzle plates based on key features such as precision, customization, scalability, and material compatibility.

Global online manufacturing platform Hubs has just published its 3D Printing Trend Report 2023, sharing an overview of the current state of the 3D printing industry as well as highlighting the trends that are shaping its future. Here is a summary of the report and a brief look at its key takeaways. For all the insights, download the full report below.