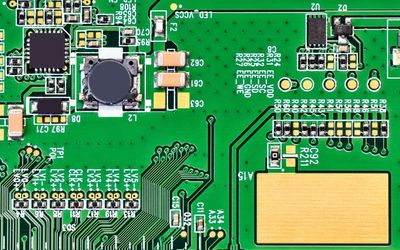

Filled vias are via holes that are completely filled and closed with conductive or non-conductive material or copper plating. The filled via is one of the many realizations of PCB via covering, specified by industry standards. This article covers the definition, benefits, processes, applications, and challenges of filled vias.

Tagged with

electronics

ORGANIZATIONS. SHAPING THE INDUSTRY.

Murata Electronics

Electrical and Electronics Manufacturing

Murata is a global solution provider and the market leader in the design, m...

37 Posts

View more

Latest Posts

Railways are more energy-efficient than other modes of passenger transportation, with CO₂ emissions per ton-kilometer roughly one-seventh those of passenger cars. The difference is more pronounced over long distances, and high-speed railway networks contribute substantially to energy savings in transport infrastructure.

What are Robotic Assembly Lines? History, Components, Advantages, Limitations, Applications, and Future

Robotic assembly lines have revolutionized production processes, enabling manufacturers to achieve high levels of efficiency, productivity, and quality.

PCB Panelization is a PCB manufacturing technique. It involves the grouping of several small printed circuit boards to form a single array, which is known as a panel. Panelization is commonly employed in PCB manufacturing because it saves time and cost. This article discusses the conditions, design considerations, methods, types, and benefits of PCB panelization.

Controlled impedance in printed circuit boards involves the regulation of resistance exerted by signal traces. It is determined by characteristic factors of PCB fabrication, such as trace width and copper thickness. This article discusses controlled impedance and the essentials of its execution in PCB manufacturing.