Mounting Holes and What to Watch out For

Picking the right fastener can be tricky.

The wrong fastener can cause problems

This article was first published on

www.macrofab.comMounting holes are one of the most popular ways to attach PCBs inside enclosures and on other flat surfaces. Most of the time mounting holes are never given a second thought beyond making sure they are in the corners of the PCB. However, there are a couple of things to watch out for when you are using mounting holes in your product.

Pick A Fastener First

The most important thing is to pick the fastener you are going to use first. This might be already chosen for you if you are using a preexisting enclosure. The fastener being used will dictate the size of the hole needed and how much keepout/clearance you will need around the mounting hole area for the head of the fastener.

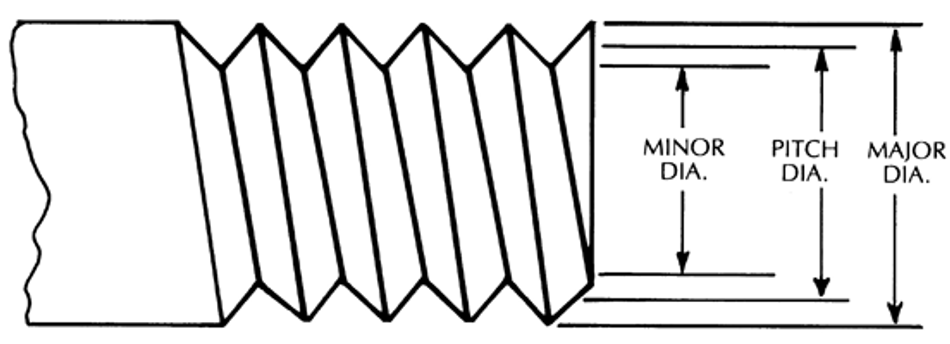

For the hole diameter look up the major diameter of your fastener and then round up to the nearest normal drill size. This should give your mounting hole enough slop. FR4, the material that PCBs are made out of, does not like to be force threaded and could result in the mounting hole cracking or splitting open if there is not enough clearance around the fastener.

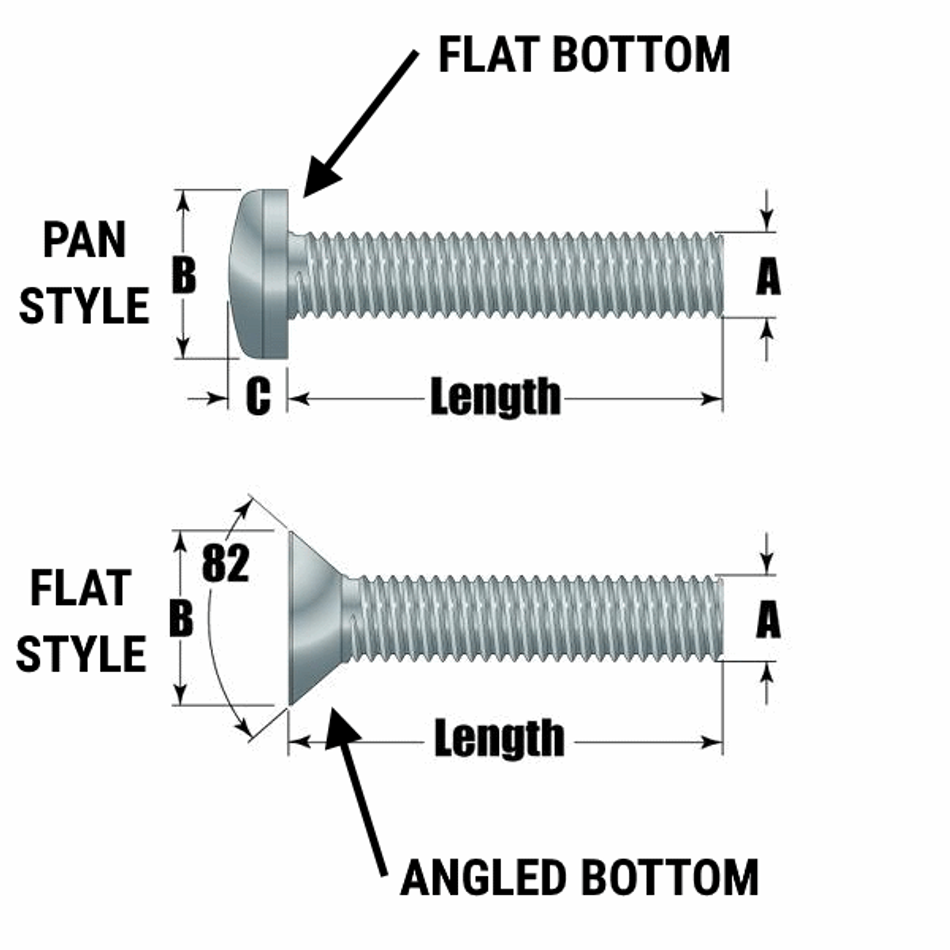

The head of the fastener should be flat on the bottom instead of angled. This is slightly confusing as the naming conventions for fastener heads relate to the top of the fastener instead of the bottom of it. A “flat” style fastener is designed to be countersunk into the material and should be avoided when using mounting holes. The angled bottom of the head of a “flat” style fastener can cause stress fracturing on the PCB.

Head Room

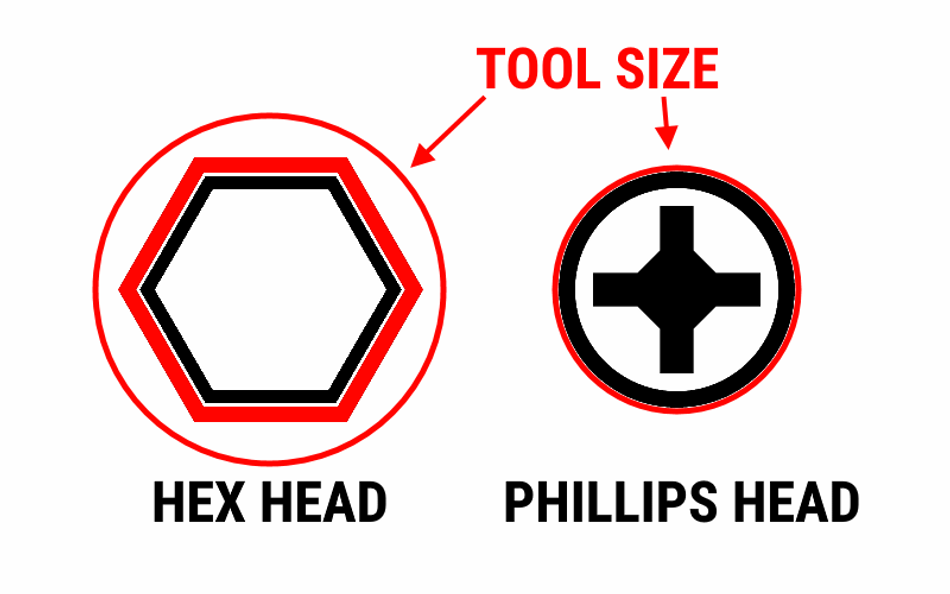

Clearance around your fastener's head is another aspect to look at. Sure the head of the fastener is a known diameter but another thing to look out for is what is the tool used to attach the fastener. If it is a Philips or Allen style fastener you will not have to worry too much as usually the screwdriver is smaller than the head of the fastener but this might not always be the case with smaller screws and fasteners. A Hex-style fastener that requires the tool to go on the outside of the head will call for more clearance.

Making sure components on your PCB are out of the way for easy tool access is overlooked often. Heatsinks, TO-220 style ICs, and large capacitors need to have adequate clearance away from the mounting hole to enable easy tool access. This area should also be devoid of signal traces, both on the surface and on the inner layers. Soldermask is not a very robust layer to physical damage so a fastener’s head may scrape the solder mask and bridge the signal layers on the outer, surface layers. Inner layers may be crushed and broken as well as the fastener torques down on the FR4.

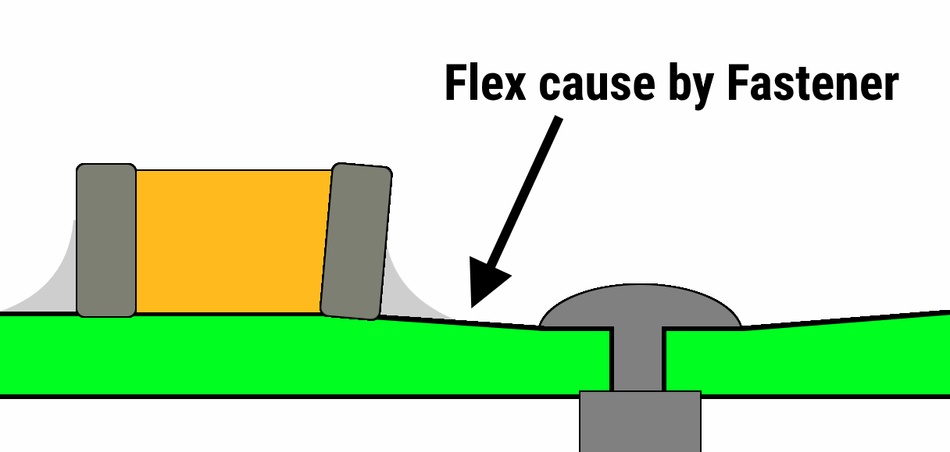

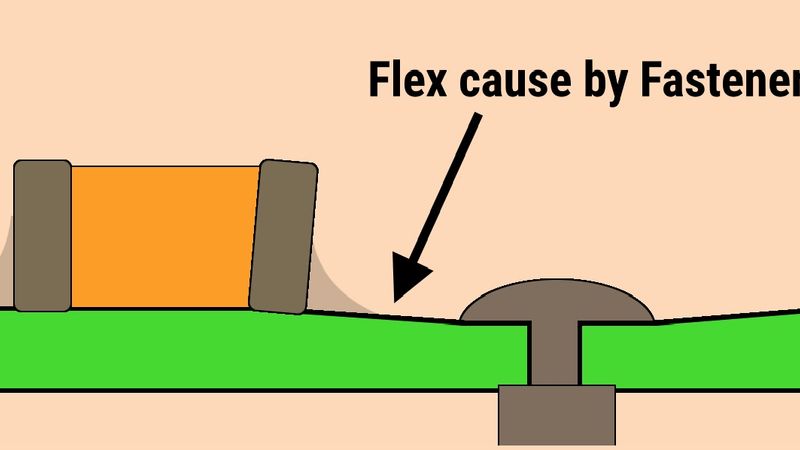

Cracking Ceramic Capacitors and Board Flex

When a fastener is installed into a PCB and tightened it will cause a slight amount of board flex as the fastener crushes the FR4 into the standoff. This slight amount of flex is enough to cause micro fractures in solder paste and inside ceramic capacitors. TDK has a great video about flex cracking inside ceramic capacitors. It is advisable to keep ceramic capacitors and other brittle components (ferrite beads) away from board edges and mounting holes for this reason. If you have to place a ceramic capacitor near a mounting hole find one with flexible termination caps to help mitigate any issues.

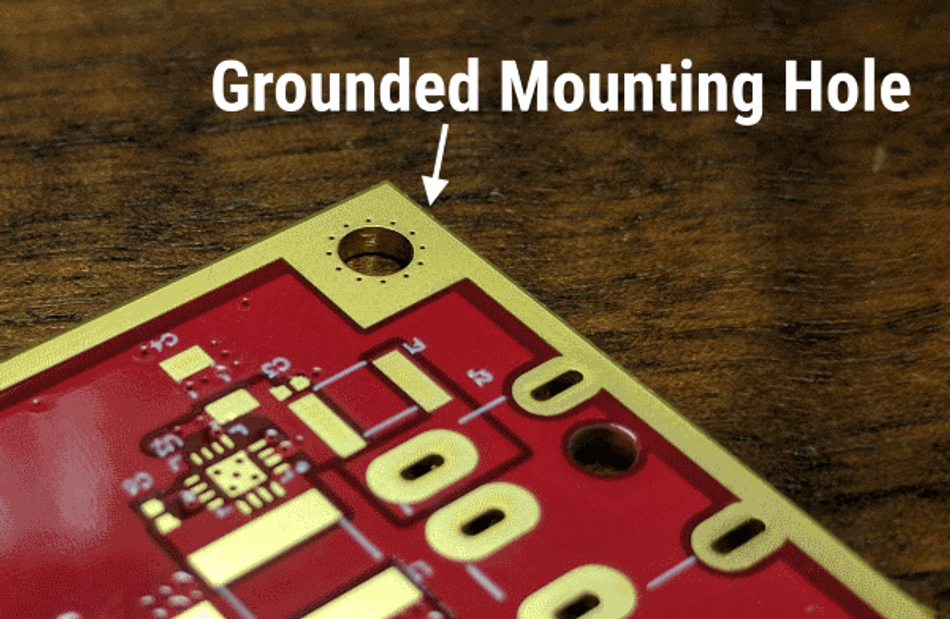

Grounding Your Enclosure

Using mounting holes to ground your PCB to the enclosure.

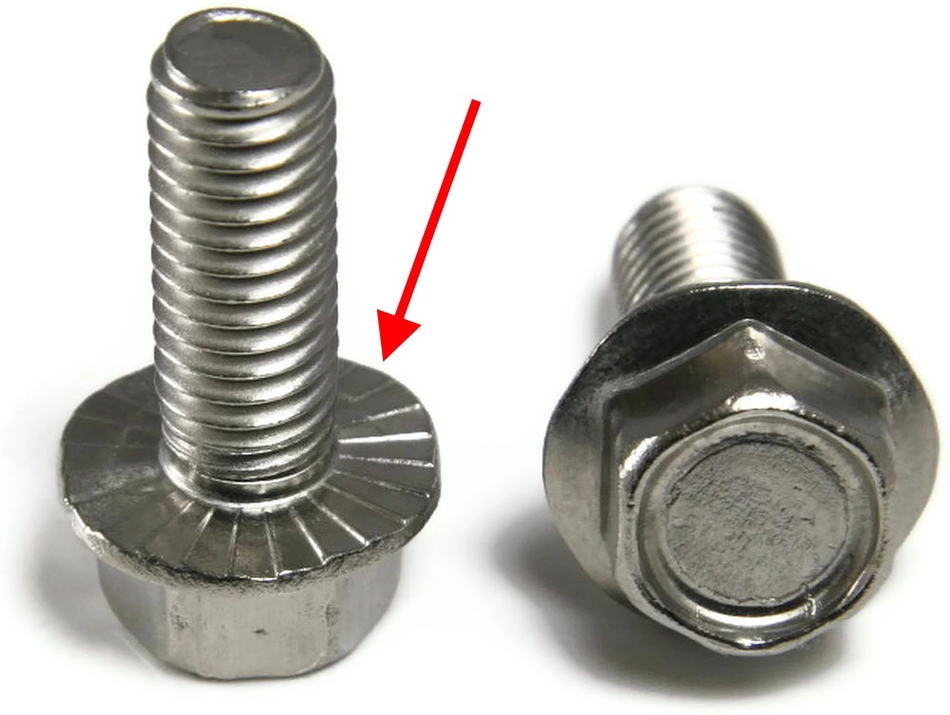

An easy way to ground your enclosure you your PCB is to actually leave copper exposed around the mounting hole. This way the fastener can contact the copper and then connect the PCB to the chassis. This is faster than having a separate wire for doing so. To improve reliability you can use fasteners that have serrations on the bottom of the head. Then paste the copper around the mounting hole which will create a layer of solder on the exposed copper. When the fastener is turned into the paste it will grab into and resist vibration better.

Tightening Up

If you want to know more about mounting holes, Stephen and I (Parker) talk about this topic on the MacroFab Podcast episode MEP EP#51: No Flex Allowed. If you have any other questions about mounting holes or other topics let us know via email or our Twitter!