Be the first to know.

Get our automation weekly email digest.

Tagged with

automation

ORGANIZATIONS. SHAPING THE INDUSTRY.

READY Robotics

Robotics & Automation

READY Robotics is a robotics software company that vastly simplifies robot ...

24 Posts

Avestec Technologies

Automation Machinery Manufacturing

We are a company in flying robotics, specializing in Non-destructive inspec...

23 Posts

Adapta Robotics

Robotics, R&D

Automate Advance Adapt. Enhancing human potential through robotic automatio...

12 Posts

View more

Latest Posts

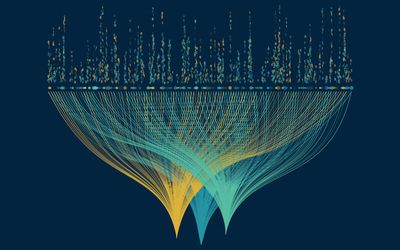

Intelligent Automation (IA) is a set of technologies and methods for automating the work of white-collar professionals and knowledge workers. Here, we present a framework for explaining its power in terms of four main capabilities—Vision, Execution, Language, and Thinking & Learning—and how they can enable business transformations, with people and business goals at the center.