How to Launch Agile Automation

Agile Automation is an approach to industrial automation and manufacturing that enables flexibility and fast deployment of automation tools in response to product changes.

Shift your business into rapid growth mode with Agile manufacturing automation

In today’s accelerating digital era, companies of all sizes are adapting rapidly to meet growing customer demands and increasing global competition. Customers today expect lower prices, higher quality, faster delivery, and more customization, all of which require manufacturers across industries to be more agile in product development. However, for manufacturers, this can be especially challenging to accomplish using traditional automation solutions that require more time, money, and labor resources. Many manufacturers are increasingly turning to a more flexible approach to industrial automation that enables them to maintain fast rates of change. This new approach is called Agile Automation.

What is Agile Automation?

Agile Automation is an approach to industrial automation and manufacturing that enables flexibility and fast deployment of automation tools in response to product changes. Unlike traditional hard-tooled automation solutions that require significant time and money to re-tool, Agile Automation enables manufacturers to quickly create and re-create solutions whenever needed. Agile emphasizes continuous testing and tight-knit cross-functional teams, which is inherent by nature to many businesses.

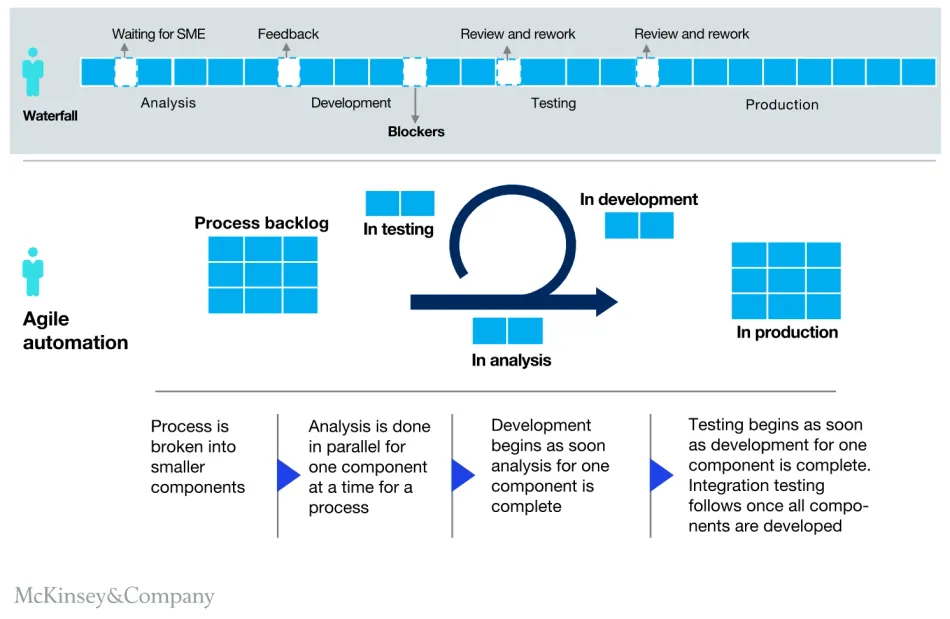

Unlike the “Waterfall” model, where production is linear and steps are followed one after another, Agile enables multiple cycles of production that allows for faster changes. All analysis, development, and testing are broken into parallel phases, as can be seen in this exhibit by McKinsey:

Agile methodology was originally developed for the software development industry to help break down large projects into smaller and more manageable parts. Today, it is the gold standard for industrial automation as well.

Principles of Agile Manufacturing

There are four main principles of Agile Manufacturing that can be applied in many manufacturing environments:

- Iterate Faster:

- Deliver small pieces of value more frequently, instead of focusing on creating a perfect product in the first try. Multiple iterations allow for more testing of different solutions, which results in superior products.

- Flexibility:

- Given the complexity of external forces impacting your business – including global competition, economic conditions, changes in customer demands, etc. – be flexible in order to ride out the volatility.

- Bottom-up:

- Instead of a more traditional top-down approach to decision-making, use a bottom-up approach where ideas and decisions are made between all layers of the business, including operators and engineers.

- Augmentation:

- Empower factory workers’ capabilities through new tech tools, including computer-vision assisted quality checks and error-proofing instructions.

Why switch to Agile Automation?

Agile Automation has been adopted across industries primarily because of its ability to reduce the time it takes to share business needs, customer feedback, and tech developments. There are many additional benefits to Agile Automation, including:

- Decreased time to market for newly manufactured products

- Increased cross-functional team collaboration

- Increased customer satisfaction with small pieces of value being added to products more regularly

- Decreased overall risks by breaking down processes into smaller components

- Increased revenue with faster product

How to launch Agile Automation

In order to launch Agile Automation, manufacturers will need to reorganize their teams and apply the principles of Agile manufacturing to their organization. Here are four key steps to keep in mind when launching Agile automation in your manufacturing operations:

- Change team structures

- Manufacturers will need to form small cross-functional teams or “pods” that each contains one Product Owner, developers, testers, IT workers, and key business stakeholders. The Product Owner would need to have expertise in the automation technology being implemented.

- Identify trigger-driven stories

- Agile Automation breaks down product development into smaller, more manageable components using “trigger-driven stories”. User actions or data availability are examples of “trigger events”. After identification, both the actions needed to respond to the event and the output created the need to be clarified. By clarifying both the inputs and outputs of each story, pods can work in parallel and increase production speeds.

- Control prototype and product releases

- In Agile Automation, manufacturers can plan to release prototypes more regularly in test environments and receive quick feedback on performance. In contrast, production releases can be more strictly released in controlled schedules to ensure that launches are coordinated with all departments in the business.

- Support organizational change

- Transforming to Agile production is a major change in culture to organizations of all sizes. Small businesses may consider hiring outside Agile Automation consultants to act as dedicated Agile program support to help teams undergo changes and evaluate the success of new methodology on production efforts.

For manufacturers that are willing to commit to change, Agile automation offers immense potential to drive business flexibility and productivity. Though there may be growing pains with the Agile transformation journey, a thoughtful application of principles and an organizational change to an “Agile mindset” are sure to help your business succeed in this digital era of manufacturing.