Tagged with

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

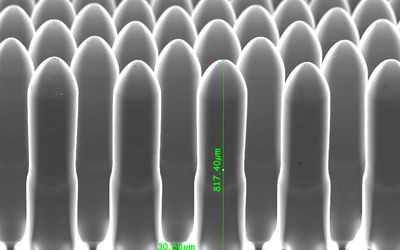

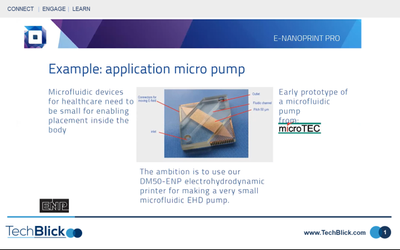

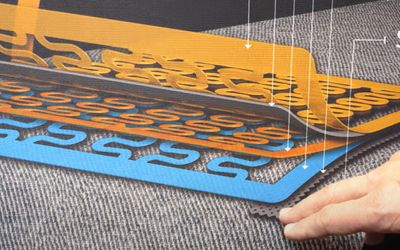

A unique new approach of printing functional materials with unparallel precision and repeatability. Technology called Ultra-Precise Deposition (UPD) is a nanodispensing method capable to print high density and high viscous materials with the resolution down to 1 µm in feature size and with high ratio of width to height after single pass. For this method material extrusion is controlled by a pressure, which means it is not supported with high electric field. Thanks to this there are no limitation if the substrate is conductive or dielectric.

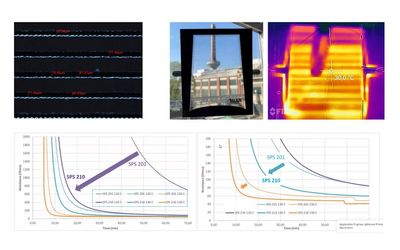

Silver nanoparticle inks improve every year. These improvements are often incremental, but very important. One ever-present direction of development is towards inks which offer ever higher conductivity levels at a low curing temperature and a short curing time. This a critical figure of merit because it opens more substrate choices, saves time, and lowers energy consumption costs.