Custom 3D Printed Medical Devices: Trends and Opportunities

Alongside aerospace, automotive, and defense, health care has long been—and will continue to be—one of the key revenue opportunities for 3D printing (also known as additive manufacturing) technology.

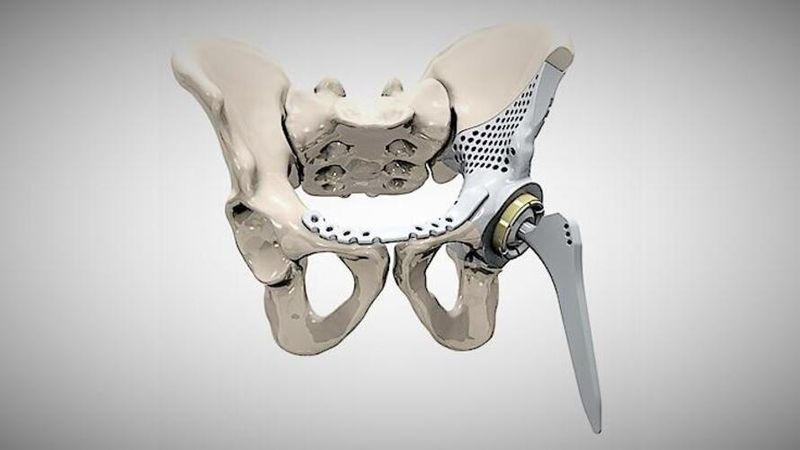

Figure 1: 3D printed hip implant. (Source: MTAA)

As a digital manufacturing process that does not require a lengthy intermediate stage like mold making, 3D printing makes it easy to turn a digital design into a custom medical device in a very short space of time[1].

Several types of 3D printing can be used in medical applications, each offering distinct advantages. Technologies include fused deposition modeling (FDM), selective laser melting (SLM), and stereolithography (SLA). Plastic 3D printing processes like FDM offer a low-cost route to prototypes and models, while metal processes like SLM can be used to make functional, biocompatible implants.

The range of possibilities for 3D printing in health care is impressively wide. The category of printed medical devices includes—but is not limited to—visual prototypes, medical models, surgical guides and fixtures, molds for medical and dental devices, machine components, internal implants (Figure 1), and external prostheses.

This article goes over the basics of custom 3D printed medical devices, including current trends and the main pros and cons of the technology when used in health care.

Trends in 3D printed medical devices

Use of 3D printers in the medical industry is a hugely significant area of additive manufacturing, spanning several applications, technologies, and materials. The global market for 3D printed medical devices is expected to grow from $2.29 billion in 2021 to $2.76 billion in 2022 at a compound annual growth rate of 20.4%, according to a recent report from the Business Research Company.[2]

Several trends are driving this growth, though arguably the most impactful at present is the direct fabrication of functional, biocompatible medical implants tailored to a patient’s unique anatomy. Such implants can currently be found in areas like orthopedic (i.e., spine, hip, shoulder, ankle) and cranio-maxillofacial (i.e., skull, face, neck) surgery.

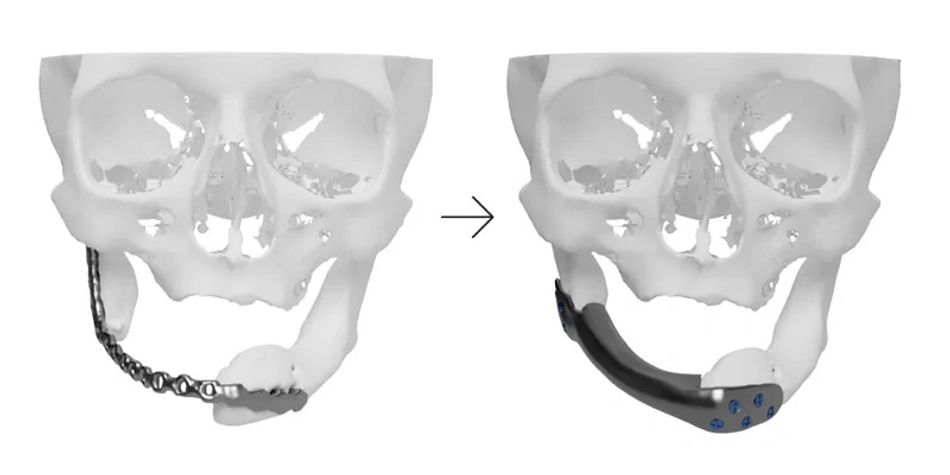

Using metal additive manufacturing processes like SLM, medical professionals can fabricate patient-specific custom implants using medical imaging data—from CT scans, for instance—as a basis for a CAD 3D model. The implant can be fabricated in a titanium 3D printing alloy (such as Ti64) that is non-toxic and biocompatible (Figure 2).

3D printed titanium implants are significant for several reasons. Not only is it fast and affordable to fabricate a patient-specific implant for 3D printing, but the implant can also be printed with a porous internal structure that promotes organic bone growth around and even through the implant. Creating such a precisely porous structure is impossible with forming processes like casting and subtractive processes like CNC machining.

Another trend in 3D printed medical devices is the establishment of point-of-care 3D printing facilities. This means setting up 3D printers not just in laboratories, but in hospitals too, giving health care providers immediate access to custom devices like surgical guides and models. Guides are used during a procedure to direct the surgical instrument to the right place on the body, while models are typically used before a procedure to give a surgeon a clear picture of the body part they will be operating on.

Processes like FDM are generally safe to use in non-industrial environments, as they do not require strong chemicals or produce large amounts of toxic fumes. This shortens the lead times for items like surgical guides and models, which can significantly improve surgery success rates by giving surgeons extra information and guidance during a procedure.

Another key application of medical 3D printing is the fabrication of custom prostheses. A range of technologies can be used for this application, including low-cost processes like FDM, in addition to a wide range of printable materials. This is also one of the more established applications of 3D printed medical devices, with successful examples going back to the early 2000s. [3]

Advantages and current limitations

There are several reasons why 3D printing has proven itself as a valuable technology for the fabrication of medical devices. As in other industries, 3D printing can be very fast and cost-effective when making parts in small quantities, because it does not require expensive tooling (e.g., steel molds) to make a part. This in effect makes 3D printing best suited to low-volume fabrication, such as the printing of one-off custom medical devices.

Another advantage of 3D printing in health care is its fully digital nature. Because parts are fabricated using computer instructions and digital 3D models (rather than manually fabricated using technical drawings), part designers can use medical imaging data as the foundation of their part design. This ensures that devices like implants or surgical guides will be precisely fitted to the patient’s unique anatomy.

In the 3D printing of titanium implants, the biggest obstacle is the additive manufacturing hardware itself. SLM systems can cost hundreds of thousands of dollars, which is prohibitively expensive for many health care providers. Metal 3D printing hardware is also more challenging to use than plastic 3D printing hardware. Machines often have a large physical footprint, and metal powders must be stored and handled with extreme care, as inhaling the metal particles can be dangerous. Furthermore, these hardware systems require inert gasses such as argon or nitrogen, which must also be stored and handled in a controlled environment.

Another major obstacle to the adoption of 3D printing in medicine (including relatively safe processes like FDM and SLA) is the relative newness of the technology. In the US, technologies, materials, and devices must receive regulatory approval from the Food and Drug Administration (FDA). Although the administration is generally amenable to 3D printing—it offers guidance on the development and testing of printed medical devices—the uncertainty around these new technologies can prove a stumbling block to development.

Conclusion

3D printing isn’t currently suited to the mass production of low-value components, but it excels at producing high-value items in small quantities. Titanium spinal implants, lightweight prostheses, and surgical guides—all of which can be tailored to an individual patient’s anatomy—are perfect examples of such items, which makes 3D printing a highly valuable technology in the medical industry.

Of course, the evolution of 3D printed medical devices is ongoing. While 3D printed patient-specific implants and prostheses have made a significant impact, there are other exciting areas of medical 3D printing that are still in their infancy. 3D bioprinting, for example, deploys additive processes for the precise arrangement of human cells and could someday be used for the on-demand 3D printing of viable human organs, potentially saving the lives of countless patients.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

References

[1] Grandview Research. 3D Printing Market Size, Share & Trends Analysis Report By Component (Hardware, Software, Services), By Printer Type, By Technology, By Software, By Application, By Vertical, By Region, And Segment Forecasts, 2022 - 2030. [Internet]. 2022 [cited 2022 Nov 11]. Available from: https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis

[2] The Business Research Company. 3D Printed Medical Devices Global Market Report 2022. [Internet]. 2022 [cited 2022 Nov 10]. Available from: https://www.thebusinessresearchcompany.com/report/3d-printed-medical-devices-global-market-report

[3] Ventola CL. Medical applications for 3D printing: current and projected uses. Pharmacy and Therapeutics. 2014 Oct;39(10):704.