Tagged with

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

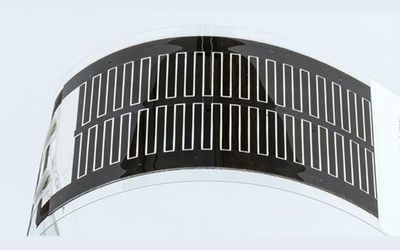

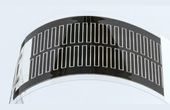

Experimenting in the world of Flexible Hybrid Electronics (FHE) comes with a variety of hurdles. Printing technologies are vastly different in terms of materials compatibility and have pros and cons that make them suitable for particular applications. Choosing materials that match the printing technology you intend to use is the most important decision you’re going to make. But what if one could print, digitally, using any paste and ink on any substrate? Read more

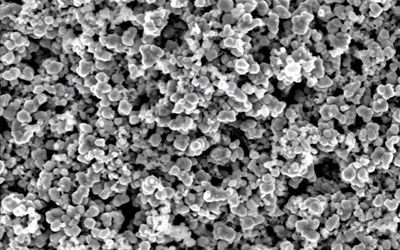

Will copper nanoparticle inks finally come of age to disrupt the dominance of silver in the conductive paste business?

Cost of production has been a major barrier despite the fact that Cu raw material prices are far lower than Ag. This is because this large raw material cost difference does not often get translated into equally large nanoparticle dispersion or ink costs. Can this be overcome?

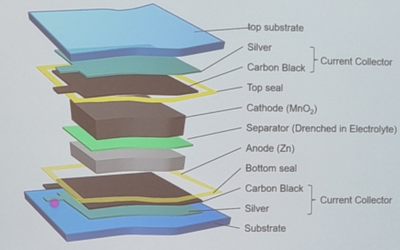

How rechargable disposable thin printed batteries can be produced and used to reliability power IoT products?

This article describes the TAeTTOOz printable battery technology developed by Evonik and acquired by InnovationLab for upscaling and mass production. In this article, you can learn about the operating principles, the key working characteristics, the material set, production techniques, and emerging applications of this technology

The progress of screen printing towards fine line printing has been incredible going from 100 µm features before 2010 to 70 µm to 2015 to 40 µm in 2018 and now pushing - in development- towards 20 µm and less. In parallel, the wet thickness of the printed line have gone down from 12um or so in 2018 to now just 4um.

As microLEDs inevitably shrink in size, the micro-bumping requirements for the microLED dies becomes more challenging. Direct wafer-based printing based on gravure offset techniques offers a promising solution in this regard. Indeed, this is another field where printed electronics can play a role.