Tagged with

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

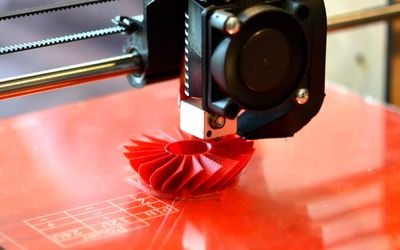

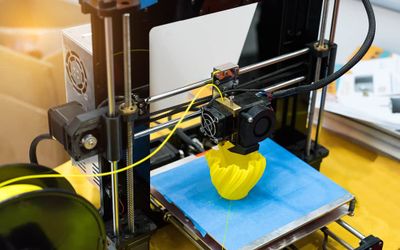

Although 3D printing was predicted to be more widespread than it has turned out to be, the technology is still undergoing enormous development. Senior Researcher David Bue is in charge of establishing DTU’s giant ‘3D printing playground’, where new records for miniature printing are currently being set.

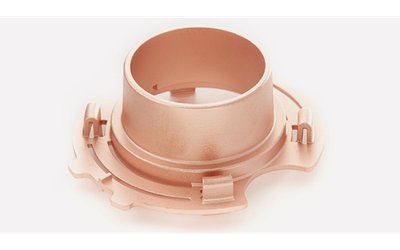

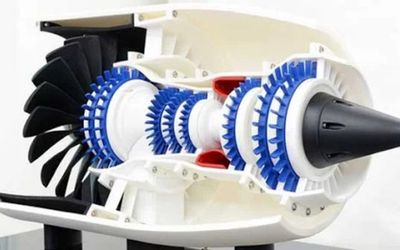

Electroforming is an additive manufacturing process specialized for the production of high precision metal parts. Its uniqueness is that you can grow metal parts atom by atom, providing extreme accuracy and high aspect ratios. Typical precision of a electroformed part goes down to 1 to 2 μm, which is beyond what most other manufacturing technologies can reach.

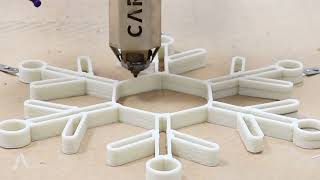

Engineers at Caltech have developed a method for 3-D printing pure and multicomponent metals, at a resolution that is, in some cases, an order of magnitude smaller than previously possible. The process, which uses water-based chemistry and 3-D printing, was described in a paper published in Nature on October 20.