Be the first to know.

Get our 3d printing weekly email digest.

Tagged with

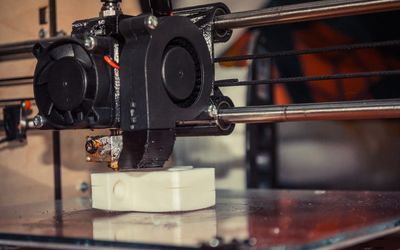

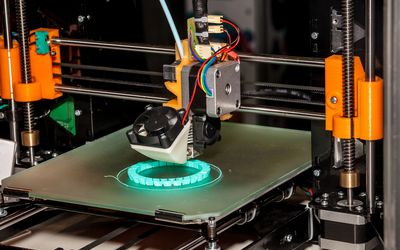

3D Printing

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

View more