Engineering with a Massless Mindset

Engineers have tremendous leverage in humanity's race to curb the most disastrous impacts of climate change. Massless offers a framework to accelerate innovation and decelerate climate change at the same time.

1. massless 2. less mass 3. less waste 4. less movement

Engineers build the world. But at what cost to the world?

Massless offers a framework to accelerate innovation and decelerate climate change at the same time. We don't all need to hide in a cave. Quite the opposite. We need to be leveraging every technology available to change our approach to product design, reconfigure our global manufacturing supply chains, and engage the power of consumer choice and education to change the culture of commerce.

Engineers have tremendous leverage in our race to curb the most disastrous impacts of climate change. Obviously, a young engineer can go work for a solar company, or a battery startup, or design the next generation of carbon capture. What is less obvious is that engineers can have a tremendous impact on climate by re-imagining how anything is built. E=mc2. Mass is energy. Energy is mass. We need to be applying the principles of sustainability to every design. The planet cannot wait.

The massless mission is to reduce global energy usage by 25% by the year 2050, leveraging the power of distributed digital manufacturing. This is a mammoth target, and it will require deep changes to our entire global manufacturing ecosystem, but it is possible. We selected this target based on modeling done in a 2018 research paper published in Energy Policy, where the authors show different scenarios for how digital manufacturing can impact global energy usage. In the different scenarios, they model the impact to be between 5-27% by 2050. massless is the mission to achieve the top end of that range. To do that, we need to change the culture.

In this article, I am going to outline the four massless principles that every engineer can begin to apply immediately to any and every project that they are currently working on.

1. Massless.

Thanks to Moore's Law, compute power is cheap, abundant and energy-efficient. Bill Gross calls this "bits over atoms". If you don't need to make a physical object, don't. Leverage the power of advanced simulation and augmented reality to work out the kinks before you build. polySpectra has created a free tool, polySpectra AR, that allows anyone to instantly view their CAD files in augmented reality, in their own workspace on their own phone or tablet, without needing to download any app or install any special software. Our hope is that designers and engineers will use this tool for their "looks like" prototypes, which would have otherwise ended up in a landfill.

2. Less mass.

30% of US energy is used to move people and stuff around. According to the US Department of Energy, reducing the weight of a car by 10% can save roughly 7% on fuel. Engineers need to be leveraging new advancements in topology optimization, lightweighting and advanced materials to create the lightest weight component that will successfully meet the design criteria. To help engineers with lightweighting, we recently created a tutorial on lightweighting for resin printing, which includes a free nTopology notebook for any engineer to apply to their project.

3. Less waste.

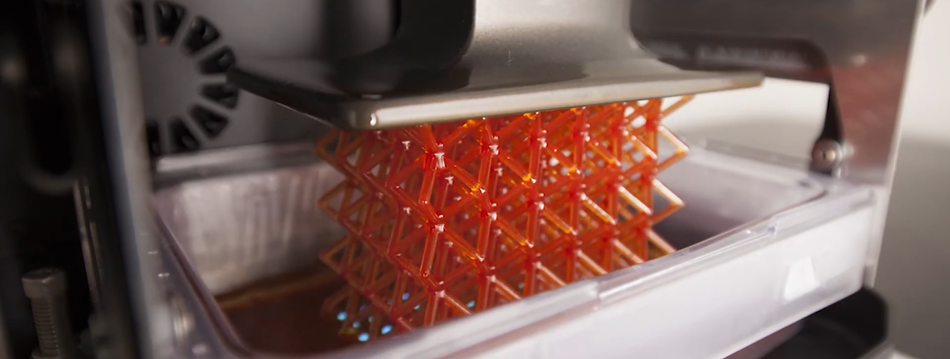

polySpectra's DLP-based additive manufacturing process uses about 50x less energy than an injection molding press. Additive manufacturing is capable of printing the precise mass, in the precise geometry, and in the precise quantity needed - with little to no waste. Most consumers are unaware of the carbon footprint of the products that they buy, these wasteful externalities are not visible or rationally priced. Today, it is too cheap for companies to create tons of trash. We have become addicted to the "infinite shelf space" of online retail. But the planet is not infinite. What if the product didn't exist until it was ordered? And then only the number of units that were ordered were produced? Consumers can still experience abundance, choice, prosperity - and we can do it without wrecking the planet.

4. Less movement.

I'll say it again: 30% of US energy is used to move people and stuff around. Digital manufacturing can have a tremendous energy impact by providing a lower carbon footprint alternative to traditional manufacturing. It can have a huge energy impact by enabling the next generation of light-weight transportation vehicles. But the really massive impact comes from "bits over atoms" - instead of sending components halfway around the world 4 times before the product is fully assembled (hint: your smartphone is made this way), we will send files over the internet, to be digitally manufactured regionally or even locally. Even if we could just shift our manufacturing ecosystem to have products manufactured on the same continent as their end-user, we could massively cut the energy intensity of our built world.

To achieve the massless mission, we will need every tool in the toolbox: augmented reality, design for additive manufacturing, topology optimization, education, customer co-creation, metamaterials, virtual inventories, advanced automation...the possibilities are endless. We will also need as many innovators as possible.

We sincerely hope that you will join us on this mission. We certainly can't do it alone. As engineers - you have much more power than you might imagine. You are building the world. Are you going to build it with intention? Could you bring the massless mindset into your workflow today?

Go massless today => https://massless.dev