5 Options to Get Heat-Resistant Parts in 3D Printing

Along with prototyping, additive manufacturing has also found its way into end-use fully functional component production. In many sectors, 3D printing is employed along with conventional technologies like CNC, if not singly.

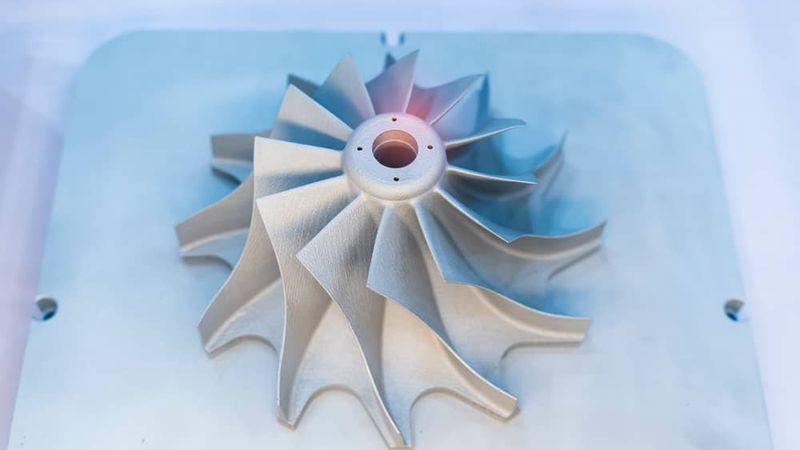

Metal 3D print with a heat-resistant material

These fully functional parts across various industries operate in various environmental conditions. Apart from being mechanically strong and chemically resistant, it is also ideal that the components are thermally resistant. This article is aimed at providing insights into five such heat-resistant 3D printing materials.

Nylon PA 12

Polyamide 12, Nylon is a thermoplastic with excellent mechanical properties. It is tough, stable, temperature and chemically resistant. These properties help in withstanding a variety of real-time environmental conditions faced by end-use parts.

PA12 Nylon (SLS) parts have good temperature resistance where the thick parts remain dimensionally stable and intact in temperatures about 163 °C, while thin and small parts start to soften and lose out on their shape when temperatures exceed 100°C. PA 12 is also bio-compatible and food safe.

3D printing technologies: Selective laser sintering (SLS), Multi Jet Fusion (MJF)

Applications: Consumer goods, jigs and fixtures, electrical housings

PC-Like Heat Resistant (Accura 48)

This material is not only high-temperature resistant but also has high strength and stiffness. This is an ideal material to use where the components are exposed to heat continuously such as under the hood automotive components. It also provides good feature details. The standard SLA printing does impart heat resistance.

The material has to undergo thermal cure in post-processing in order to enhance its thermal resistance. At 0.46MPa test pressure, PC-Like Heat Resist Translucent has a heat deflection temperature that ranges from 70 – 85°C. This heat deflection can be enhanced to about 135°C with a thermal post-cure.

3D printing technology: Stereolithography (SLA)

Applications: Electronic and lighting components, under the hood automotive components

ABS

ABS is capable of withstanding temperatures of up to 100°C. Its heat deflection temperature is between 88-89°C and its melting point of about 200°C. Apart from its excellent thermal properties, ABS is also known for its toughness and impact resistance which facilitates the printing of parts that are subjected to high-stress applications. It has a glass transition temperature of about 105°C and is highly resistant to aqueous, phosphorus and hydrochloric acids.

3D printing technology; Fused Deposition Modelling (FDM)

Applications: Drain/waste pipes, inhalers, housing for electrical components

ULTEM 9085

This has a good strength–to–weight ratio, very good impact strength with high heat resistance. ULTEM 9085 is a highly flame retardant. Along with prototypes it is also used to manufacture tools in the aerospace and automotive industries. It has a glass transition temperature of 186°C and a heat deflection temperature of 153°C. With its superior mechanical strength and lightweight, ULTEM 9085 is suitable for the production of end-use components.

3D printing technology: Fused Deposition Modelling (FDM)

Applications: Jigs, fixtures, composite moulds

Inconel 718

Inconel 718 is a nickel-chromium based high-strength superalloy which is corrosion, pressure and temperature resistant. It can resist up to 700°C and melts at about 1400°C. It has a good tensile strength of 1035 MPa. Moreover, it is brittle and has excellent machinability with a hard cutting tool. It is widely used in manufacturing, military equipment and the aerospace industry.

3D printing technology: Direct Metal Laser Sintering (DMLS)

Applications: Gas turbine engine parts, compressor casings, die holders

Comparison table of heat-resistant 3D printed plastics and metals

Material | 3D Printing technology | Vicat softening temperature | Heat deflection temperature | Tensile strength |

Nylon PA 12 | SLS, MJF | 163°C | 154°C | 48 MPa |

Accura 48 (PC-Like heat resistant) | SLA | - | 135°C | 50 MPa |

ABS | FDM | 100°C | 88 – 89°C | 42.5 – 44.8 MPa |

ULTEM 9085 | FDM | 173°C | 153°C | 71.6 MPa |

Inconel 718 | DMLS | - | 700°C | 965 MPa |

The materials above are not only heat resistant but also offer good mechanical and anti-corrosive properties. Even though they vary in costs and advantages, they can surely compete with conventional materials in manufacturing end-use parts.

Learn more about 3D printing materials, their properties and their applications.