Be the first to know.

Get our pcb weekly email digest.

Tagged with

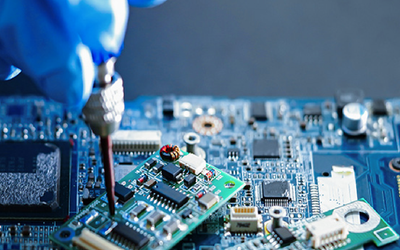

PCB

ORGANIZATIONS. SHAPING THE INDUSTRY.

HQ NextPCB

Appliances, Electrical, and Electronics Manufacturing

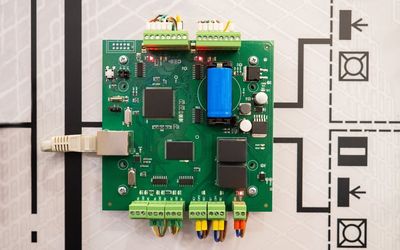

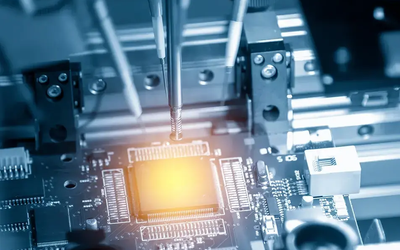

HQ NextPCB specializes in reliable multilayer PCB manufacture and assembly ...

1 Post

AllSpice

Software Development

Hardware collaboration platform 🤖 Inspired by software development princip...

View more

Latest Posts

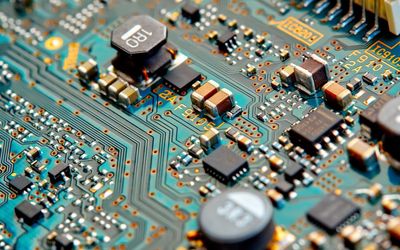

Electromagnetic Compatability protection in industry: The indispensable pillar for safe and reliable systems

In a world that is increasingly dependent on electronic technology, EMC protection plays a vital role in a wide range of industries. Whether in automotive, aerospace or power generation, EMC protection is essential for the reliability, safety and performance of electronic systems.