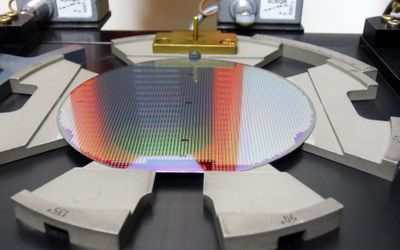

Wafer thinning is a part of the semiconductor manufacturing process. It is essentially grinding off the backside of the wafers to control their thickness and is useful for the production of ultra-thin wafers. These flattened wafers are used to effect stacked and high-density packaging in compact or microelectronic devices. This article discusses the meaning of wafer thinning, along with its various techniques and significance.

Be the first to know.

Get our electronics weekly email digest.

Tagged with

electronics

ORGANIZATIONS. SHAPING THE INDUSTRY.

Murata Electronics

Electrical and Electronics Manufacturing

Murata is a global solution provider and the market leader in the design, m...

37 Posts

View more

Latest Posts

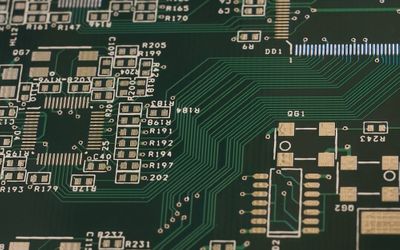

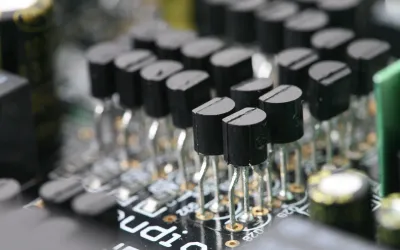

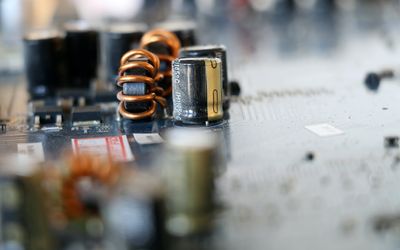

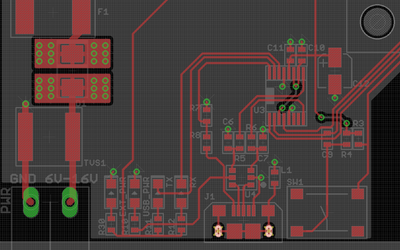

The rigid, flex and rigid-flex PCBs are all types of printed circuit boards. The rigid PCB is the traditional board and the base from which the other two variations came about, in response to industry and market needs. Flex PCBs introduced versatility to PCB fabrication and rigid-flex combines both for increased performance. Learn more about these board types, their benefits, disadvantages, and applications in this article.