Top Things You Should Know About Prototyping PCBAs in the USA

What to know about the benefits of domestic prototyping

Prototyping PCBAs in America is becoming more common.

This article was first published on

macrofab.comTop Things You Should Know About Prototyping PCBAs in the USA

Prototyping PCBAs in the USA is becoming the norm for more and more companies. Ongoing logistics and production challenges in Asia have pushed many engineering teams to reconsider how they approach PCBA prototyping. Decision-makers aren’t confident anymore that Asian manufacturers can consistently deliver cost-effective prototypes on time.

Earlier this year, COVID-19-related shutdowns in China delayed production for organizations worldwide. Meanwhile, shipping costs are still high. The Ukraine/Russia conflict looms over the global energy sector, extending shipping concerns and contributing to intermittent power outages in China’s prefectures and associated manufacturing stoppages.

Additionally, sourcing materials continues to be a problem everywhere. Modern electronics manufacturing is still hampered by these realities, which can make prototyping difficult.

Prototype PCBAs enable engineers to test different designs and catch flaws before full production runs. They also provide a way to upgrade legacy products and de-risk investments in new products. But moving prototyping to a different region of the world isn’t as simple as leaving one manufacturer for another.

Finding the right prototype PCB partner requires thorough due diligence and careful planning. Thanks to platforms like MacroFab, electronics engineers can now find viable prototyping options in the U.S. more easily than before.

Considerations before switching prototype PCB vendors

Changing PCB prototyping vendors is risky with any redesign or start-up. Often, tribal knowledge comes from previous partners. Some manufacturers make design tweaks over time or use substitute components without documenting the changes. As a result, companies sometimes don’t have the latest design notes when looking for new PCB prototype opportunities. It’s important to gather as much information as possible about previous PCBA prototype and production runs before changing vendors.

Furthermore, companies should ensure that any new prototyping facilities have the capacity, capabilities, and equipment to maintain design intent. Moreover, they should be able to improve upon previous designs in future iterations. Failure to think ahead in this area can lead engineering teams to shop around again when it’s time to upgrade designs.

If the goal is to use the same manufacturer for prototyping PCBs and full-scale production, engineers also need to determine if potential partners have access to crucial components. Otherwise, companies will run into sourcing challenges that delay mass production. Finally, engineers should ask new CMs how they intend to maintain design integrity over time. It is important for both sides to agree on items such as:

- Who will maintain documentation?

- What form will documentation take (i.e., physical vs. digital)?

- How often will documentation be subject to review?

Keeping this information updated is essential for enabling factory portability and efficient production. It’s also what maximizes PCB prototyping performance in the U.S.

U.S. prototyping benefits

The above considerations can assist companies in understanding the advantages of prototyping PCBAs in the United States. Additionally, engineering and manufacturing can communicate more easily. Simplicity is a plus when prototyping involves fast feedback loops and iterations. Having engineers and manufacturers separated by oceans and 12- hour time differences makes it more difficult. Prototyping facilities nearby improve quality control, communication, and iteration speed.

Protecting your IP is also easier in the U.S. than in markets like China. Designs and prototypes are less likely to get stolen here because our legal system has strict intellectual property rights protections. Meanwhile, institutions and governments worldwide have criticized China’s lax IP laws for creating a breeding ground for IP violations.

Furthermore, moving prototype PCBAs to the U.S. decreases the likelihood of unexpected delays. The inherent risk associated with transporting prototypes across the ocean is eliminated when prototypes are made in nearshore facilities. Additionally, prototype deliveries are more reliable, faster, and less expensive.

PCB prototyping in the United States is not without its challenges. For modern electronics manufacturing, working with MacroFab makes sense.

How MacroFab enables U.S.-based PCBA prototyping

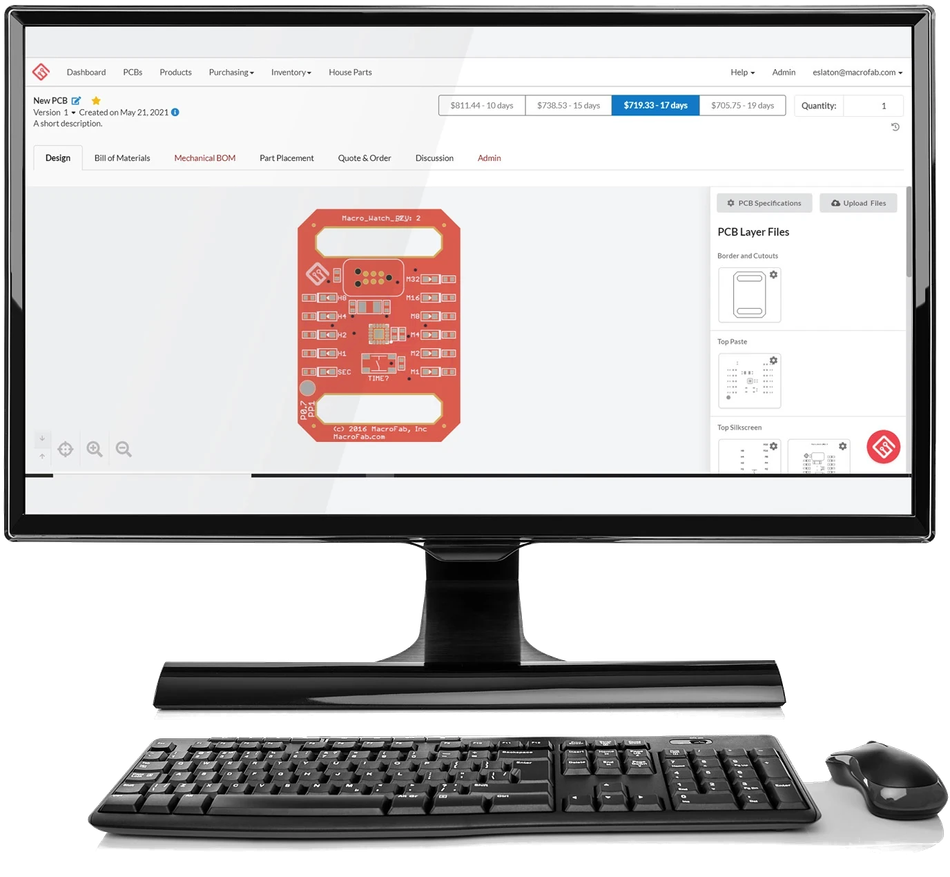

When it comes to starting up new PCB prototyping operations in the U.S. MacroFab solves key pain points. With MacroFab, you can access a vetted network of North American factory production lines, including those with prototyping capabilities. By using the MacroFab platform, engineers can assess PCBA prototyping delivery and scaling options while accessing real-time component availability information along with options for selecting alternative parts based on risk and cost.

As companies scale up, MacroFab has reliable production lines across North America, including cost-effective manufacturing options located in Mexico. Users can rely on our engineering support staff to help them find the best locations for prototyping and mass production.

MacroFab also maintains a digital thread that tracks all design updates and changes. This is maintained on MacroFab’s cloud manufacturing platform, which is accessible to any employees who need it; you can choose who has authorization. There is no need for engineers to pass documentation back and forth, so tribal knowledge will remain in control. All important documentation can stay within MacroFab, where it’s safe and secure from IP theft, tampering, or improper use by unauthorized individuals.

Last but not least, our platform is intuitive and easy to use. Within our software, engineers can upload designs, order prototypes, make updates, evaluate market conditions, and more. With our tools and capabilities, companies can accelerate innovation and mitigate much of the risk associated with overseas prototyping by moving PCB prototyping to the U.S. The time is right to make the transition and move past outdated approaches to prototyping.

View a Demo

Learn more about how MacroFab makes U.S.-based PCBA prototyping easier.