Be the first to know.

Get our additive manufacturing weekly email digest.

Tagged with

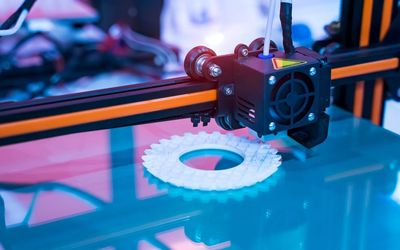

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

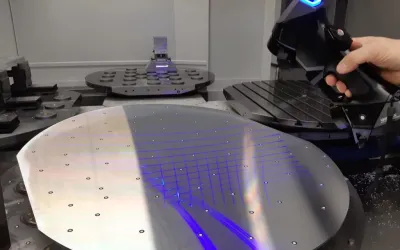

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more