Drying your FFF filaments, and keeping them dry: an overview

If you are printing with engineering-grade FFF materials, you likely need to dry your filaments before using them. This article will give an overview of your filament drying options and their advantages and drawbacks!

Drying filament in an oven

Drying is the process of removing moisture from material. In the FFF process, this is related explicitly to removing water from your 3D printing filament to utilise its potential fully. As discussed in a previous article, moisture will affect the appearance and properties of your printed parts. Several methods can be used to remove moisture from filaments and several other methods that can keep the filaments dry whilst printing.

Methods of Drying Filaments

Most drying techniques generally involve heating the filament to a set temperature. The heat excites the water molecules that have bound to the polymer and allows them to move freely and diffuse to the surface. The higher the temperature, the faster a filament dries, and the less residual moisture is left in the filament. However, when drying a material, it is important not to subject it to an excessively high temperature, as this could soften or melt the material. The temperatures and duration generally recommended for drying moisture-sensitive materials can be found in the table below. As can be seen, the drying temperature is related to the heat resistance of each material.

| MATERIAL | TEMPERATURE | TIME |

| PVA | 50 °C | 2-4h |

| PET-G | 60 °C | 2-4h |

| Nylon | 70-90 °C | 4-8h |

| PC | 80 -100 °C | 4-8h |

| Ultem 1010 | 150 °C | 4-6h |

| PEEK | 150 °C | 3-4h |

| PEKK | 150 °C | 3-4h |

There are various methods and tools that one can use to dry their filaments, and they vary in effectiveness, reliability and cost.

Oven Drying

Oven drying is probably the most widespread technique used to remove moisture from FDM filaments, both by enthusiasts and also for professional users. This technique seems simple enough, set your oven to the desired temperature, pop the spool in for a set time and voila! Your filament is dry. However, this technique has its own pitfalls, the rate of success will depend on both the oven used and also on the user.

Temperature: Each oven will behave differently, depending on its feature. A basic oven might move, have very good temperature control and overshoot the set temperature. This might cause the oven to get too hot, especially on startup or after opening the oven door. In fact, it is always advisable to measure the temperature in the oven using a separate probe to ensure that the set temperature in the oven is maintained. Another factor which needs to be considered is uneven temperature distribution leading to hot spots in the oven. This can be alleviated by using a fan-assisted oven that will distribute the heat better. One other issue with the oven getting too hot is that it might cause the material spool itself to deform, which could render the filament unusable.

Thus if you are running a business and the quality of your prints depends on having dried filament, you will probably have an oven specifically set up for drying filaments. Thus for reliable drying, one will need to buy an oven with good temperature control that is fan assisted. There are also even more expensive options available such as vacuum ovens. That being said, having a good oven still leaves one issue.

Time: Drying a spool of filament sufficiently takes time. Insert graph and data from white paper.

Furthermore, you will not know how much time a spool needs to be sufficiently dry. Thus, one would probably need to dry a spool of Nylon filament for a day or two before it can be used to ensure it's completely dry. This is a waste of time and energy.

Filament Dryers

Recently, several filament drying solutions have been implemented for use with FFF technology. These usually range from DIY solutions based on food dehydrators to specialised ovens accommodating filament spools with a filament path to the printer.

Food Dehydrators are tools designed for desiccating fruits and food. Some modifications can be used within limits to dry certain filaments. Food dehydrators work at lower temperatures than typical ovens. They can be set to temperatures of up to 70C. In reality, the temperature around the filament is usually around 50-60 C. As a result, they might not be capable of getting hot enough to dry anything effectively except PLA and PET. These devices can also be modified so that the filament can be fed into the printer while printing so that the filament remains dry during printing. That being said, if the filament is already wet, it must first be dried before it can be used.

Filament dryers are machines that are meant for filament drying. Most of the time, they are specifically designed for that purpose. Low-end models are adapted from the food dehydrators mentioned earlier, and thus, they share all the features and drawbacks of food dehydrators.

Filament dryers can offer a more reliable and tailored drying experience. Higher-end filament dryers can be specifically designed for drying filament. They come in all shapes and sizes, but typically all involve some dial or touch screen to set the temperature and a space for the filament spool to fit in. Various types of dryers use different methods to dry the filament. Some dryers work alongside the printer, allowing the filament to enter and be used in the printer as it is drying.

Add that filament dryer can keep.filament dried and can dry a broader range of materials as they reach a higher temp. These solutions, however, still require that all the filament is predried for a long time before it can be used.

Keeping filament dry

It seems it is not enough just to dry the material. One needs to maintain filament dryness after active drying. As discussed in a previous article, filaments can absorb enough moisture in a few days. The image below shows a CF-nylon filament that was dried in the oven and started showing printing artefacts related to moisture.

Several solutions, such as dry boxes or specialised storage cabinets, are on the market for keeping filaments dry. These units, however, all have their drawbacks. Typically low-end solutions require constant monitoring and user input to ensure the desiccant is dry. More advanced solutions are typically bulky and require an active power connection. However, the biggest drawback of these solutions is that they cannot dry the filament on their own. This means that they have to be used in conjunction with an oven, mainly if the filament being used has already absorbed moisture.

Another potential drawback of these solutions is that bigger spools won't always fit in the drying chamber. In addition, some filament spools can warp and degrade in the oven, especially after multiple drying cycles. This can potentially cause the filament to unspool.

How does Drywise solve the issue of drying and keeping filaments dry?

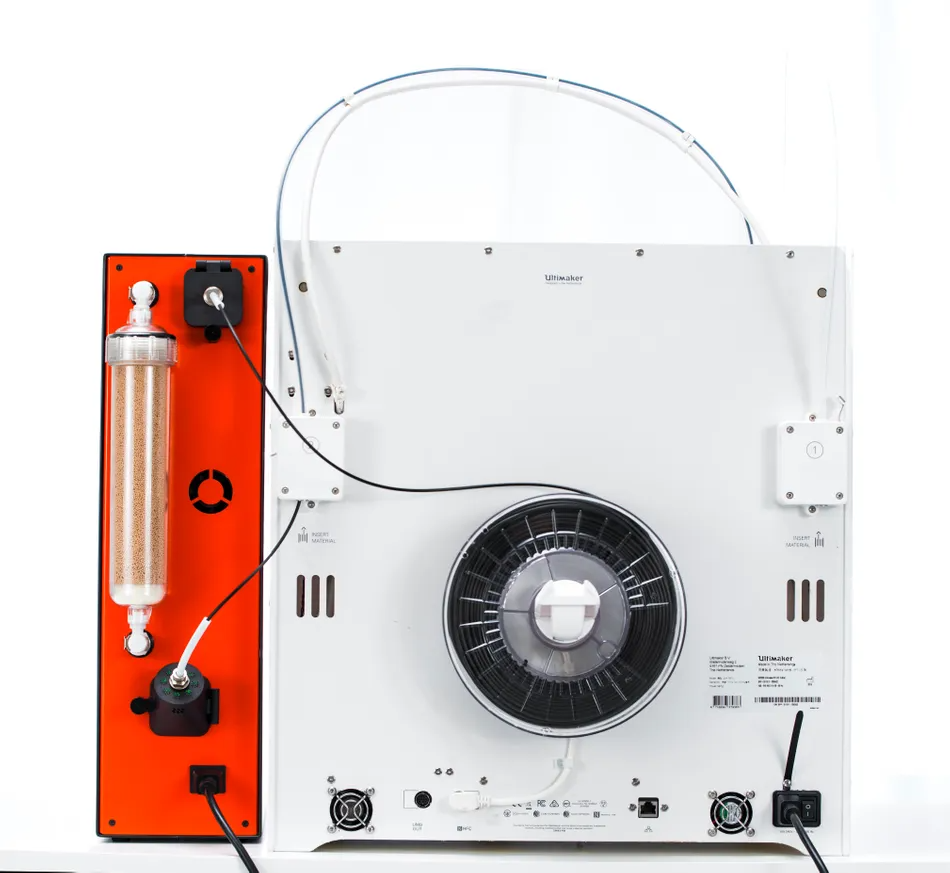

Drywise aims to address these issues since it dries the filament in line. This means Drywise only dries the filament portion as it is fed into the printer. The printer, thus, is being fed with freshly dried filament as it is printing, ensuring consistently dried filament. As a result, Drywise addresses both the need to dry filament and also the need to keep it dry. Furthermore, since the spool is not housed in the unit itself, any spool size can be used with Drywise.

Additionally, Drywise is an intelligent filament drying solution since it monitors the temperature and humidity of the filament as it is being dried. This means that each material is conditioned as required. The user can select the material type being dried, and using pre-calibrated drying profiles, the device will take care of the rest. Furthermore, the device will be able to accept new material profiles via firmware updates to ensure its compatibility with an ever-growing list of materials.