All you need to know about Test 3D Prints

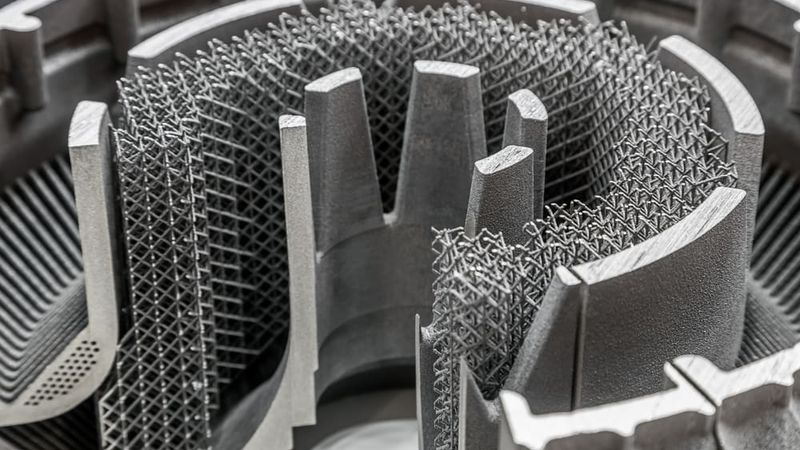

In 3D printing, achieving consistent and high-quality prints requires more than just a good printer and filament. Calibration and quality control are essential components that can make or break your 3D printing experience.

3D Printing Test

More often than not, beginners in 3D printing will immediately begin printing without first inspecting or calibrating their device. This might work sometimes, but on other occasions the situation can turn into a complete disaster. A test print is what can be used to check if everything is functioning properly or not. These are test prints like 3DBenchy, calibration cubes, negative space, torture tests, etc. A 3D printer's capabilities are carefully tested with using torture test models. One model may assess the printer's capacity to produce overhangs or span bridges, for instance. Additional forms of torture could evaluate surface polish or dimensional correctness. Some could experiment with the slicer's speed, temperatures, or extrusion parameters.

What are the best Test Models to test and calibrate the 3D Printer?

The calibration of the printer must be precise and reliable for the manufacturing process to be successful. Within this article, we'll examine the top test models for 3D printer testing and calibration.

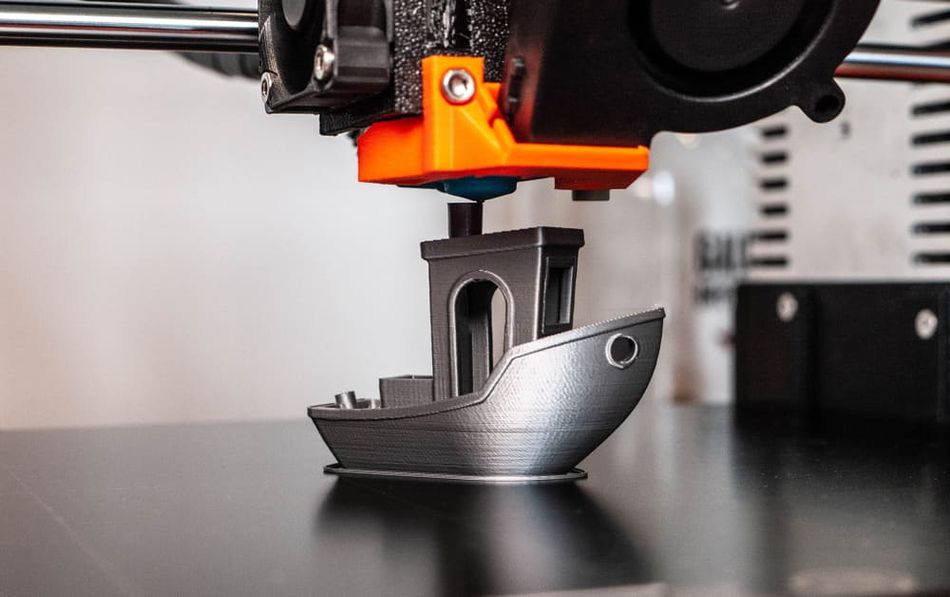

3DBenchy:

Benchy is a little 3D printed model created to evaluate the precision of the 3D printer. If the printer can produce a decent Benchy, users can take it easy since the printer is correctly lined up. Swedish 3D technology startup Creative Tools created 3DBenchy, which was released for free online. The vessel includes several little elements that can be challenging to print, like horizontal apertures, cylindrical shapes, overhangs, flat surfaces, and arched ways.

Benchy can help users in testing a variety of things, such as:

Overhangs: Printing the Benchy might be difficult because of its numerous overhangs and curved sides. This makes it a useful prototype to evaluate the printer's overhang configurations.

Bridging: Throughout the printing operation, there are a lot of gaps in the Benchy which must be filled. These gap fillings help test the printer's bridging capabilities.

Surface quality: 3DBenchy is a fantastic model to utilize when assessing the surface quality of the prints since it contains a variety of distinct surface textures and features.

Start printing out the Benchy on the 3D printer to employ it as a calibration tool, and afterwards the print can be checked for any overhangs, bridging issues, or quality problems. If users encounter any issues, then they can modify the necessary printer parameters to achieve the required outcomes.

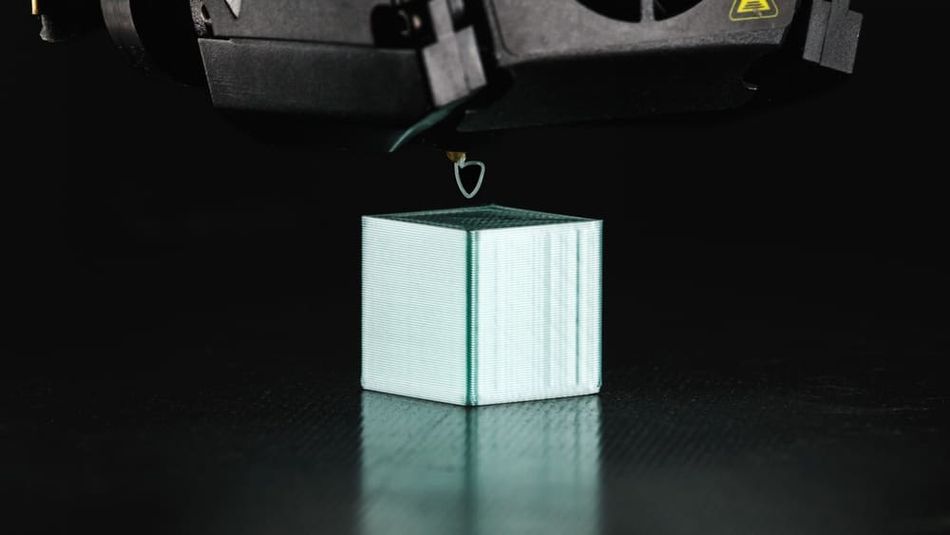

Calibration Cube:

The calibration cube is among the most popular test items used for 3D printer calibration. The only component of this straightforward design is a cube with the measurements 20mm x 20mm x 20mm. The cube should have smooth edges and a flat top and bottom. With a calibration cube, users can contrast the exact measurements to the desired parameters since it is simple to measure the cube's dimensions after it has been produced. This can assist users in locating any problems with the extrusion rate, bed leveling, or other factors that can be influencing the print's accuracy.

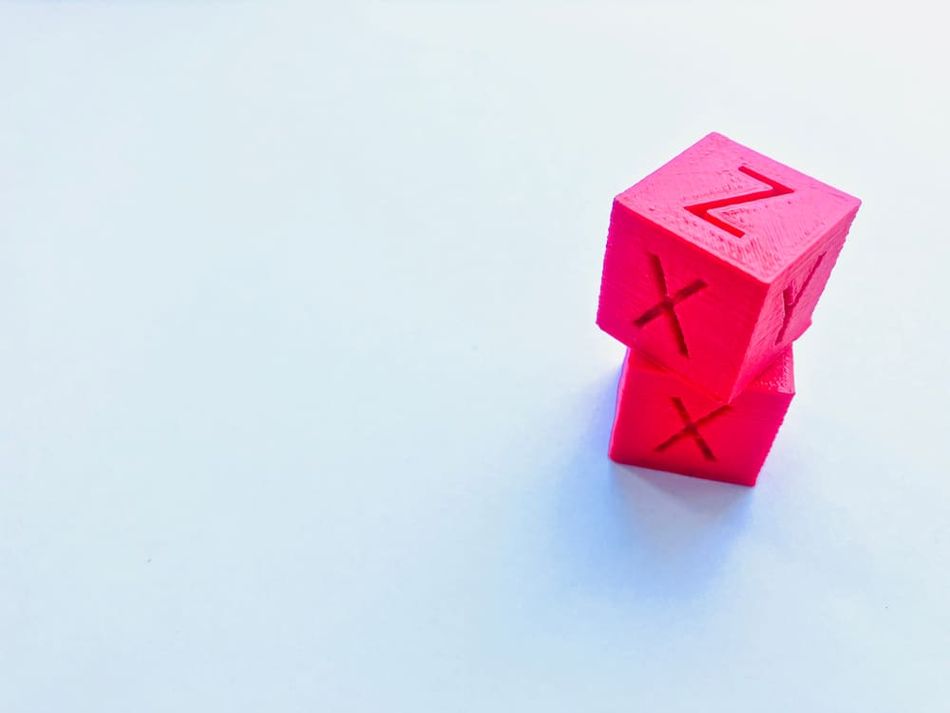

XYZ Cube:

The XYZ cube and calibration cube both have testing purposes for your 3D printer's precision and accuracy. The XYZ cube, however, has a few extra characteristics and dimensions, such as inner cavities, slots, and curved surfaces, making it a little more complicated. This makes it an excellent model to test a variety of printer configurations and capabilities.

The calibration cube is a straightforward, quick, and easy prototype to test the printer. Its main objective is to help users in fine-tuning the steps per mm of the printer's axis to increase dimensional accuracy. Nevertheless, one can also measure vibration, temperature, and extrusion.

Hollow Cube:

Hollow cube testing is a calibration technique used to validate the extrusion rate precision of 3D printers. For the test, a hollow cube is printed, and the measurements are measured to make sure the cube was printed correctly. Designers may be certain that the device is calibrated properly if the measurements are exact. If otherwise, users can change the printer's settings to make the next print more accurate.

Additionally, the hollow calibration cube also tests the oozing, retraction rate, and bridging configurations of the printer since it is completely hollow in between. Any sagging in the upper part of the print would indicate that the printer extrusion rates need to be double checked to prevent such problems in the actual prints.

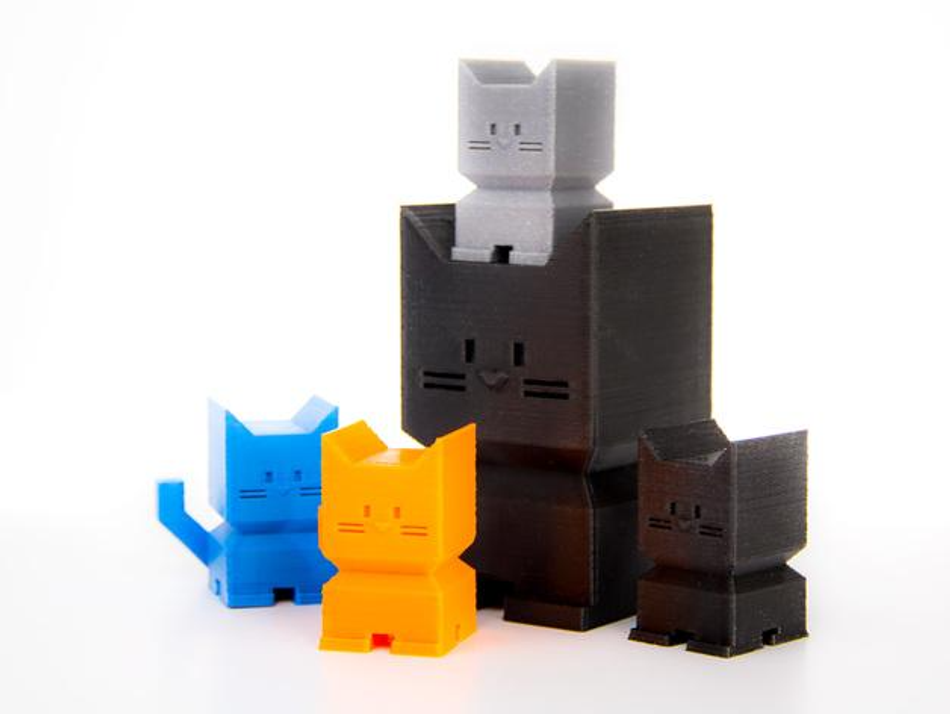

Cali Cat:

Cali Cat is a simple test that checks if the printer can execute enhanced prints and is the ideal replacement for standard calibration cubes. Before going on to more sophisticated printing, the Cali Cat model ensures that you have a firm grasp of the fundamentals by including the linear dimensioning checks of a calibration cube. Besides, it contains other complex characteristics including bridging, a 45° overhang, and surface imperfections in the face. Users need to configure their 3D printer if there are any flaws in the Cali Cat print.

Cali Cat or Calibration Cat can be printed in around 30 minutes, making it a quick and simple method for calibrating the 3D printer to consistently produce high-quality parts.

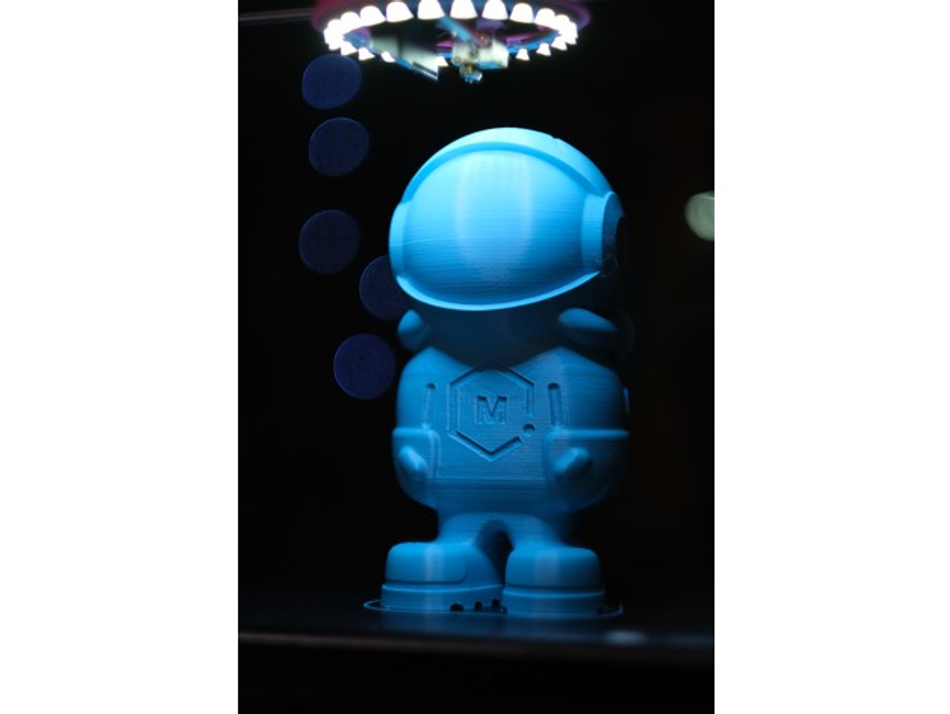

Phil A. Ment:

The endearing astronaut mascot of MatterHackers, Phil A. Ment, was created to assist producers in precisely calibrating their printers. The corporation's description states that "Phil offers various functions particularly to test your printer." The smooth dome of Phil's headgear and a few tiny embossing and inset features are among the torturous objectives. Overhangs, cylinders, bridging, and notches are additional complex obstacles.

Scaling this test print shouldn't be a problem because the lowest and largest documented prints are 5 and 1397 mm tall, respectively. Users may also select from a number of Phil variations, including SLA-optimized models as well as a Santa Phil to test the capabilities of their printer.

Temperature Tower:

The 3D printer's nozzle temperature can be tested using a test model called the temperature tower. It is crucial to get the temperature adjustment correct for every material that is being used since various materials demand differing temperatures to be printed successfully.

A tall column with several temperature zones makes up the temperature tower. Users may test a variety of temperatures in one print since each sector corresponds to a distinct degree setting. When the print is finished, inspecting the temperature tower can determine the settings which were most effective for that specific material.

PolyPearl Tower:

The PolyPearl Tower is a brand-new model from Polymaker intended to push the limits of both the 3D printer and filaments! The PolyPearl tower is an excellent build to evaluate bridging, curvature, overhangs, threading, and many other things. The extruder's flow rate is one of the key variables examined by the PolyPearl Tower test. To ensure that the printed pieces have a consistent surface texture and thus are clear of any faults, the test additionally assesses the extrusion quality. PolyPearl Tower also tests the temperature of the bed. The printed pieces' ability to adhere to the build platform is significantly influenced by the temperature of the bed.

Another crucial factor examined by the PolyPearl Tower testing is layer height and placement. The test determines if the printer's movement along the X, Y, and Z axes is accurate and aids in locating any stepper motor or calibration problems that can impair the dimensional accuracy of the 3d product.

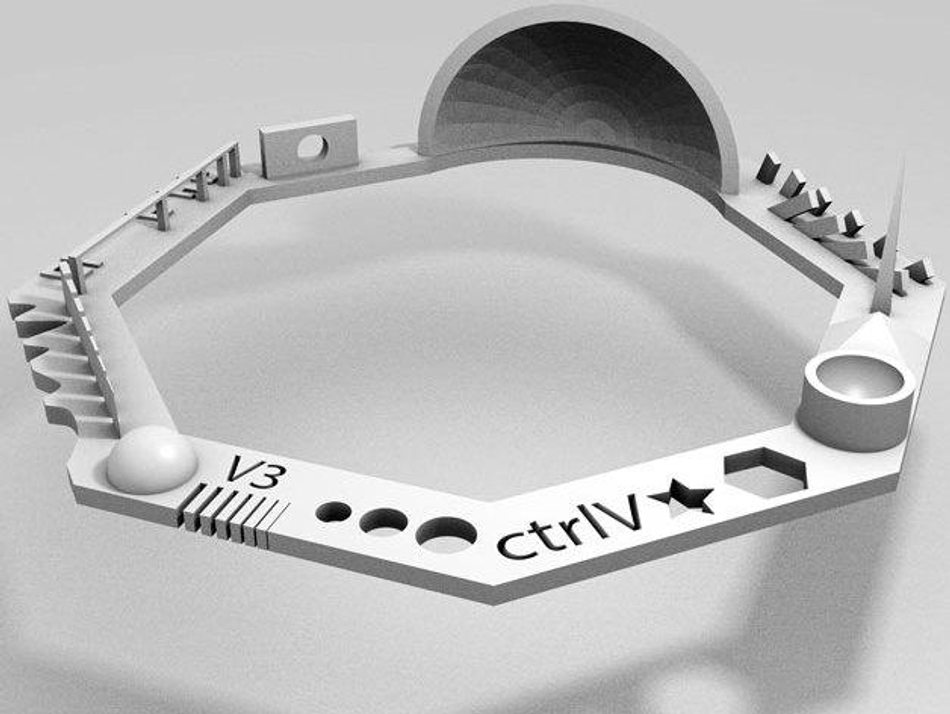

Octagon:

This eight-sided octagon calibration test dedicates every side to a select particular 3D printing issues and features an empty middle. There are a total of 21 distinct aspects assessed, including spikes, overhangs, negative space (indentations), and dimensional correctness (sharp points).

Users may test the capabilities and configurations of their printer using its elaborate and complicated design. The test confirms that all printer settings, such as bed leveling, nozzle level, and thermal gradient, are correctly set for the best print quality.

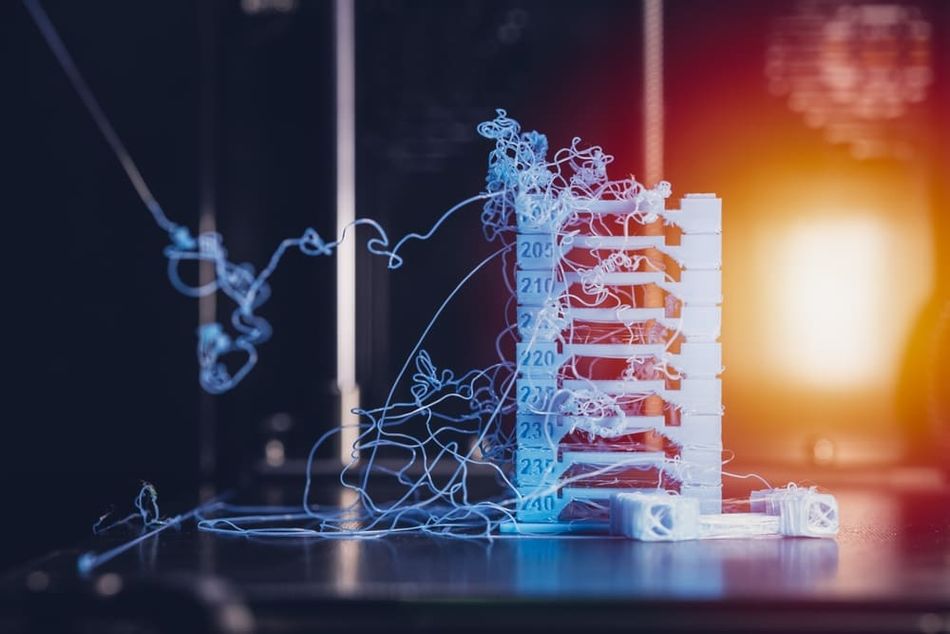

Stringing Issues

The most annoying issues users may encounter when 3D printing is stringing. It has to do with tiny filament strands that accidentally extrude into areas where printing shouldn't be happening. This unattractive mess can impair or even spoil a decent print even after it has been cleaned up. The higher the melting temperature of the filament used within 3D printing is the main cause of stringing. The substance pours out of the nozzle after melting and becoming more fluid. In contrast, if the print head isn't going quick enough or there are gaps among printed parts and the material keeps oozing out of the nozzle, it will result in the formation of strings. Insufficient retraction is also a typical reason for stringing. If the retraction specifications are incorrect, too much material may be left on the printout, which will result in stringing.

Stringing may appear innocuous at first, but it consumes a great deal of filament and can be a sign of other more serious issues. Adjusting temperature, retracting length and velocity, and printing speed can all help to reduce stringing. Using a better-quality filament, speeding up the nozzle's path, or putting a physical barrier in between the printed areas are further methods to prevent stringing.

Key Takeaways

3D printing technology is revolutionizing industrial innovation and mass production fields. Developers can fine-tune their designs by checking its functionality over a 3D printed model before sending it into the mass production phase. However, it is important to properly adjust and calibrate the printer to avoid any faults and inaccuracies appearing in the product. 3DBenchy, different calibration cubes, temperature towers, octagon torture tests are some of the test models that can help users fine tune their printer for extrusion rates, find optimum printing temperature, control the print speed, and configure their devices for dimensional accuracies. A properly calibrated printer can print out intricate models with accuracy and precision while avoiding any unnecessary issues. Users can also explore different printer models and filament materials that’d fit their individual requirements and have the best possible printed items they want.

References

1. Denise A. Meet Benchy: Your First 3D Print [Internet]. stlMotherhood. 2020 [cited 2023 Mar 14]. Available from: https://stlmotherhood.com/heres-your-first-3d-print-file/#:~:text=Benchmarks%20are%20prints%20that%20you

2. Mike. How Is 3D Printing Cost Effective? [Internet]. 3D Printed Parts. 2021 [cited 2023 Mar 15]. Available from: https://www.3dprintedparts.com/2021/01/15/how-is-3d-printing-cost-effective/#:~:text=3D%20printing%20is%20the%20most

3. Chen A. Top 10 Materials Used For Industrial 3D Printing [Internet]. www.cmac.com.au. 2020 [cited 2023 Mar 16]. Available from: https://www.cmac.com.au/blog/top-10-materials-used-industrial-3d-printing#:~:text=ABS%20(Acrylonitrile%20Butadiene%20Styrene)%20is

4. What are the Most Common Materials Used for 3D Printing? [Internet]. Dassault Systèmes. 2022 [cited 2023 Mar 16]. Available from: https://www.3ds.com/make/solutions/blog/most-common-materials-3d-printing

5. Hullette T, O’Connell J, Schendel G. Top 15: Free 3D Printer Test Print Models [Internet]. All3DP. 2022 [cited 2023 Mar 16]. Available from: https://all3dp.com/2/best-3d-printer-test-print-3d-models/

6. lammatt. Hollow Soma Cube [Internet]. www.thingiverse.com. 2020 [cited 2023 Mar 16]. Available from: https://www.thingiverse.com/thing:4680754

7. Design. Cali Cat - The Calibration Cat [Internet]. www.thingiverse.com. 2016 [cited 2023 Mar 16]. Available from: https://www.thingiverse.com/thing:1545913

8. OPPAPALAM. Astronaut Phil A Ment (180mm height) [Internet]. www.thingiverse.com. 2020 [cited 2023 Mar 16]. Available from: https://www.thingiverse.com/thing:4314611

9. Polymaker_3D. PolyPearl Tower Torture Test [Internet]. www.thingiverse.com. 2017 [cited 2023 Mar 16]. Available from: https://www.thingiverse.com/thing:2064029

10. ctrlV. Test your 3D printer! v3 [Internet]. www.thingiverse.com. 2016 [cited 2023 Mar 16]. Available from: https://www.thingiverse.com/thing:1363023

11. MatterHackers. Top Ten Calibration Prints for Your 3D Printer [Internet]. MatterHackers. 2022 [cited 2023 Mar 16]. Available from: https://www.matterhackers.com/articles/top-ten-prints-to-calibrate-your-3d-printer?rcode=YTUBE

12. Hamill S. Top 11 Torture Test Prints & 3D Printer Calibration Tests - 3DSourced [Internet]. www.3dsourced.com. 2023 [cited 2023 Mar 16]. Available from: https://www.3dsourced.com/guides/test-3d-prints-calibration/