Tagged with

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

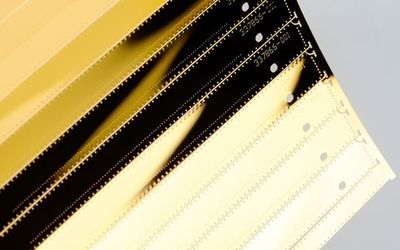

Inkjet nozzle plates are one of the most important components of inkjet print heads, as the quality of the nozzle plates directly determines the resulting printing performance of the whole system. This article introduces what an inkjet nozzle plate is, how this important component works, and how it is manufactured.

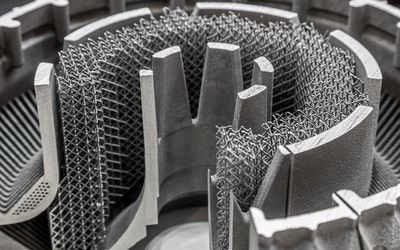

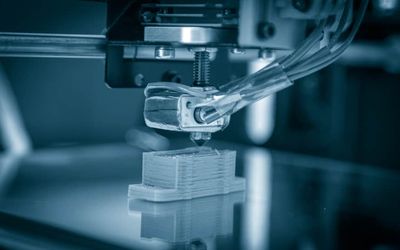

The beauty of additive manufacturing is in the flexibility these technologies provide in terms of scale, shape, and materials. Building know-how on software has allowed Caracol to leverage these skills and adapt them to working with robotics for LFAM on different processes - from its proprietary thermoplastic/composite pellet extrusion Heron AM to introducing Metal with WAAM.

Inkjet Printing for Solar Cell Manufacturing: How Electroforming is empowering the photovoltaics industry moving forward

Inkjet printing is an extremely versatile, non-contact process that involves jetting tiny ink droplets to facilitate direct printing. It has seen a surge of new applications in fields including electronics, life science, optics, and PV.

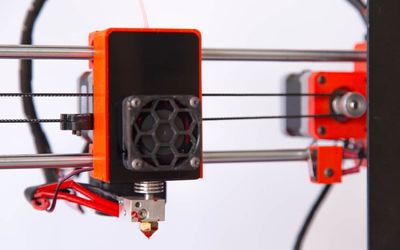

RMC Motorsport drastically reduces its production times and manufacturing costs by 3D printing end-use parts for their rally cars

RMC Motorsport, an automotive company dedicated to the rally sector, has internalized & optimized internal processes and achieved greater design capacity by involving 3D printing technology in the manufacturing process of their rally cars.