Bringing circularity to the solar panel industry

Envision a solar panel that is fully repairable, upgradable, and recyclable at high value at end of life to support an energy transition that is truly sustainable. The technology and production process will be open source to maximize its reach to all people across the globe.

This article is a part of our University Technology Exposure Program. The program aims to recognize and reward innovation from engineering students and researchers across the globe.

Community voting is now live. Vote for your favorite submission by visiting: University Technology Exposure Program Community Vote.

Introduction

Biosphere Solar is a young start-up consisting of students and recent graduates from TU Delft. We aim to utilize our background in renewable energy, industrial design, engineering, and business development to build a solar panel that is sustainable in its truest sense.

Energy is one of the most essential and basic elements that has enabled humans to achieve some of the incredible things in the past and will be in the future. But this energy generation in the present is largely dominated by fossil fuels which is leading to global catastrophes like climate change and other related issues. In this regard, solar energy is seen as one of the means with great potential to transition from the existing means of generation.

We aim to take this a step further by designing and building a solar panel that is fully circular with respect to its lifecycle with minimum waste creation. The designs and the production methods will be open-source to extend the reach of this technology to people across the globe and inspire the solar industry towards incorporating a more circular design.

About our project

Our mission is to provide a circular approach to industrial products, focusing on the solar industry. Therefore, Biosphere Solar provides a repairable, low-cost, and upgradable solar panel. We aim to market circular solar panels, which are more durable than any solar panel on the market currently. The commercialization of the product will be in three phases, starting with product sales to early adopters to build momentum, then moving towards a production line that will also be open-sourced. Finally, a product-service business model will be used as is generally most fitting to a product designed for circularity.

The solar panel developed will conform with the highest current industry standards, while also being designed with future industry developments in mind. All components in the panel can be individually replaced and recovered. The advantageous characteristics of this design compared to conventional solar panels found on the market today are its modularity which makes it repairable and refurbishable, the reduced life-cycle environmental impacts of the product, the use of recycled materials, as well as the fact that it can be upgraded when solar cell technology evolves. The repairability of the panel increases its lifetime and the upgradation of the cells will improve its efficiency over time. We are targeting an average functional life of 35 years for all components, as opposed to 20-30 years for conventional solar panels.

Problem we are trying to solve

The deployment of solar energy has been growing exponentially over the last two decades, coupled with the exponential price drop in solar energy. But, while we are on that path it is important that the transition does not introduce new challenges like critical material depletion, human rights transgression in the manufacturing process and creation of large amounts of waste at the end of life of the product. According to estimates, by 2050 upto 78 million metric tons of solar panels will have reached their end of life, and the world will be generating 6 million metric tons of new solar e-waste annually.

To address the issue of solar panel waste, the European Union has mandated the recycling of solar panels under the “Waste Electronic and Electric Equipment” (WEEE) directive since 2007. However, this has mostly been a patch on the problem, forcing the industry to send panels to recycling facilities, but not addressing the underlying limitations of the solar panel design itself. With the ‘Right to repair’ movement around the world, people are starting to realize the need to implement the repairability of products in the design phase to be able to prolong the life and more effectively recover the materials at the end of life.

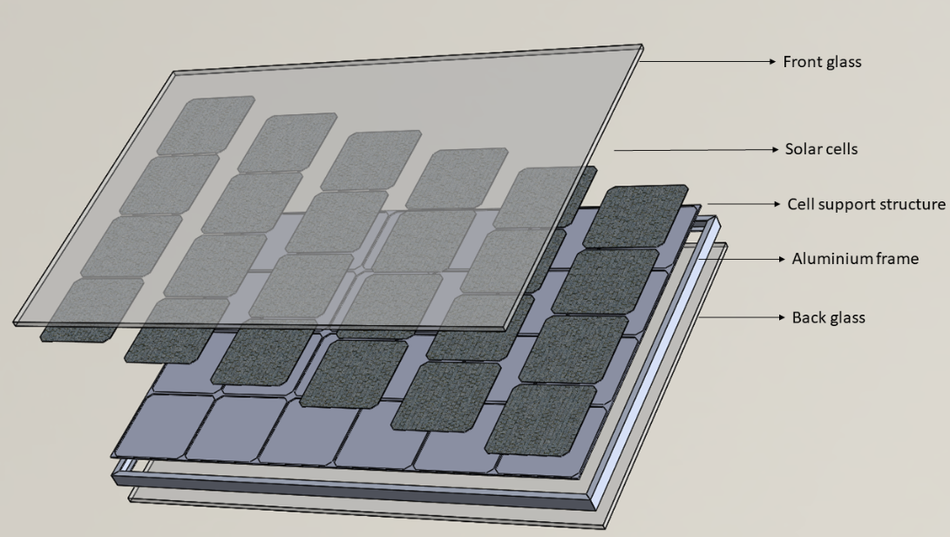

The current way of manufacturing solar panels uses a tried and tested “lamination method” for the encapsulation of solar cells. The cells are highly sensitive to moisture and oxygen, and hence this process stops the cells from degradation to guarantee the 25 years lifetime promised by the manufacturers. However, this makes it difficult to take apart the panel for repair when damaged and recovery of materials at the end of life. We solve this problem with our design by doing away with the lamination and instead of using an edge sealant to restrict the ingress of moisture and oxygen. The sealant can be removed at the time of repair or upgradation allowing access to the solar cells and making it modular.

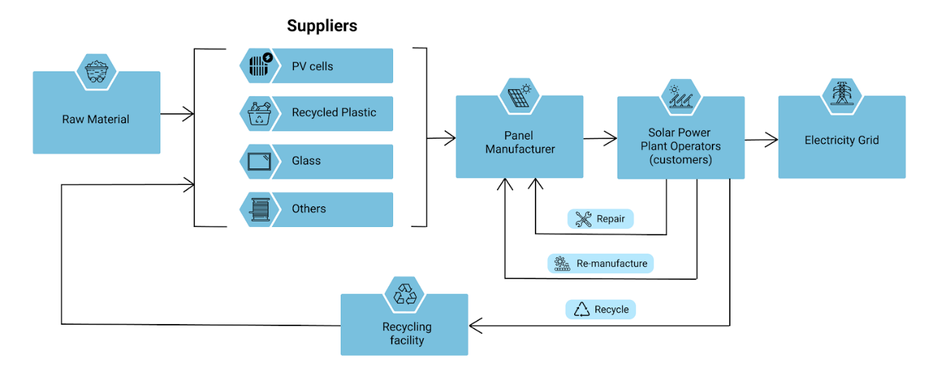

Biosphere solar will be utilizing a product-service system approach to provide value to our clients. This goes against the traditional ways of doing business where most products are made and sold in the market with little additional service to prolong the lifetime and improve the product itself during its lifecycle. Instead, we will be responsible for the after-sale needs of our client to ensure panels are operating at peak performance and the end-of-life recovery of the product. The materials will be recovered at high purity to make other solar panels that can be installed again at other sites. With the demand for solar energy growing and increasing consciousness among people about sustainability, the market is ripe for innovation to disrupt the traditional ways of conducting business.

Current state of the art of our sector

Currently, China holds a monopoly in the manufacturing of solar panels with over 90% of them being manufactured. The manufacturing is optimized for low cost and ease of manufacture. The panels are cheap and due to the drop in the prices of the solar cells due to the scale of production, the electricity generated has reached grid parity in many places, i.e. competes with electricity prices from conventional sources of energy without subsidies from the government.

Photovoltaic technology has been dominated by mostly Silicon in the past and will share a dominant share of the market in the near future. However, there have been upcoming thin-film technologies like CIGS and perovskites which show huge potential for the future. These technologies are not only more efficient in energy generation than the incumbent, but also use fewer materials by weight and require less energy in the manufacturing process. There are rapid advancements being made across the globe and the conventional means of manufacturing needs to be adapted to accommodate these technologies for scaling up.

These technologies are at the photovoltaic cell level and the construction of the support structure, or the frame would still largely remain the same. This makes our solution more attractive as with our design it is possible to replace just the cells in the panel with the latest technology available in the market instead of replacing the panel altogether. This avoids the creation of large amounts of waste and effectively recovering the materials the cells were made from. Furthermore, it brings down the levelized cost of electricity (LCOE) of solar energy and hence improves its reach to more people across the world helping accelerate the energy transition.

About the team

The team began to take shape initially through participation in entrepreneurial competitions at TU Delft where we were able to get feedback and validation from industry experts about our idea. The team has been dynamic with people contributing at various stages over the last one and a half years with a core team that has been constant. The team has expanded in the recent months to twelve members which include interns working on solving the technical challenges, others helping in developing the business model through participation in more competitions, and looking for funding opportunities.

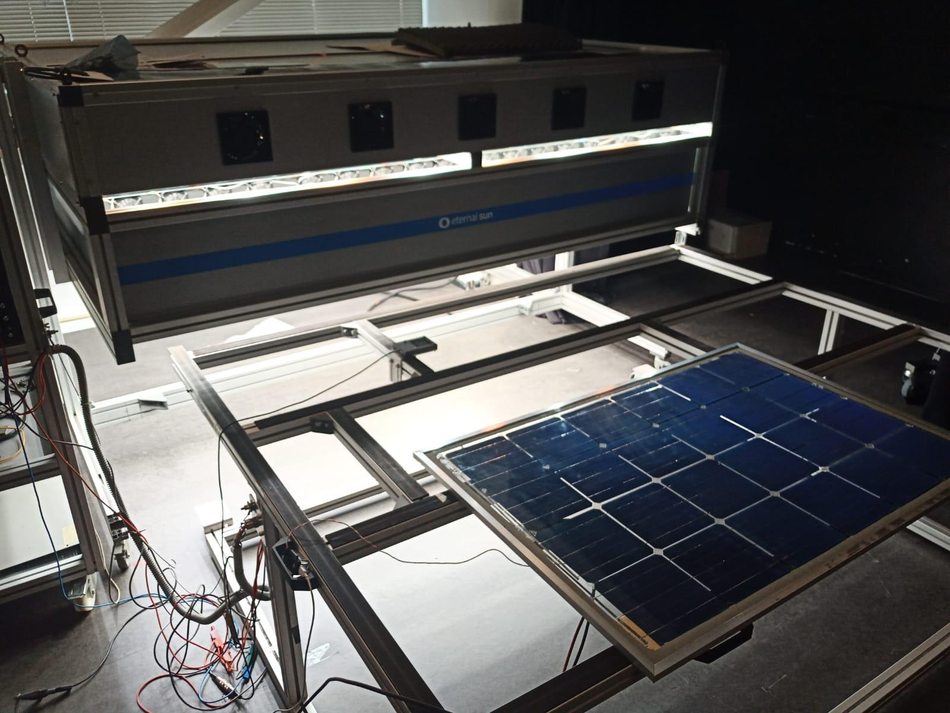

Biosphere Solar now has a workspace to fabricate more prototypes to make improvements and learn through testing it in a field lab at the University. The momentum that the team has gathered in the last year is exciting and is looking forward to bringing a circular revolution in the solar panel industry.

About the University Technology Exposure Program 2022

Wevolver, in partnership with Mouser Electronics and Ansys, is excited to announce the launch of the University Technology Exposure Program 2022. The program aims to recognize and reward innovation from engineering students and researchers across the globe. Learn more about the program here.