Be the first to know.

Get our pcb weekly email digest.

Tagged with

PCB

ORGANIZATIONS. SHAPING THE INDUSTRY.

HQ NextPCB

Appliances, Electrical, and Electronics Manufacturing

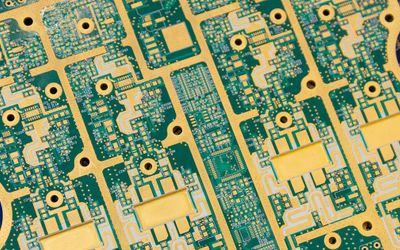

HQ NextPCB specializes in reliable multilayer PCB manufacture and assembly ...

1 Post

AllSpice

Software Development

Hardware collaboration platform 🤖 Inspired by software development princip...

View more

Latest Posts

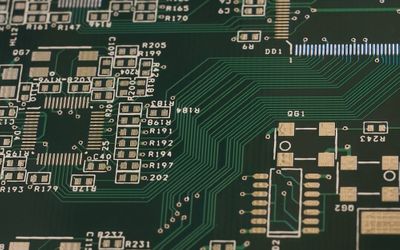

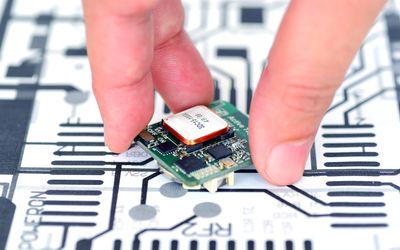

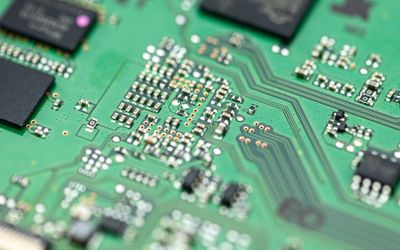

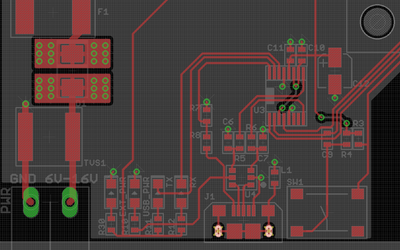

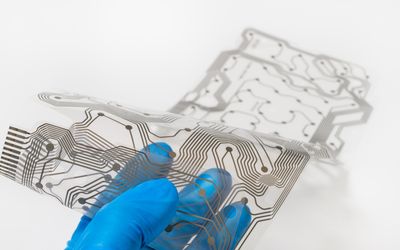

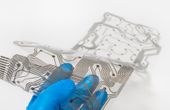

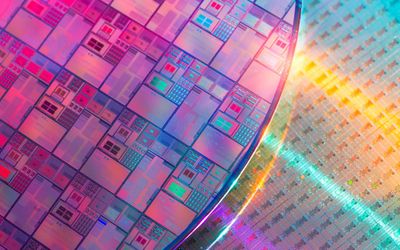

The rigid, flex and rigid-flex PCBs are all types of printed circuit boards. The rigid PCB is the traditional board and the base from which the other two variations came about, in response to industry and market needs. Flex PCBs introduced versatility to PCB fabrication and rigid-flex combines both for increased performance. Learn more about these board types, their benefits, disadvantages, and applications in this article.