A Practical Guide to Solder Flux

Solder flux has a large impact on final product quality. This article reviews how to use flux during soldering and how to decide on the right technology options for your project.

Learn more about solder flux

This article was first published on

macrofab.comA Practical Guide to Solder Flux

The assembly manufacturing process, including solder flux, has a large impact on the success of final product quality. A robust surface mount assembly maintains high reliability over the life of the product, and the soldering process and type of flux used are key contributing factors to surface mount technology (SMT) assembly success. Let’s review how to use flux during soldering and how to decide which technology and contract manufacturing (CM) partner to choose.

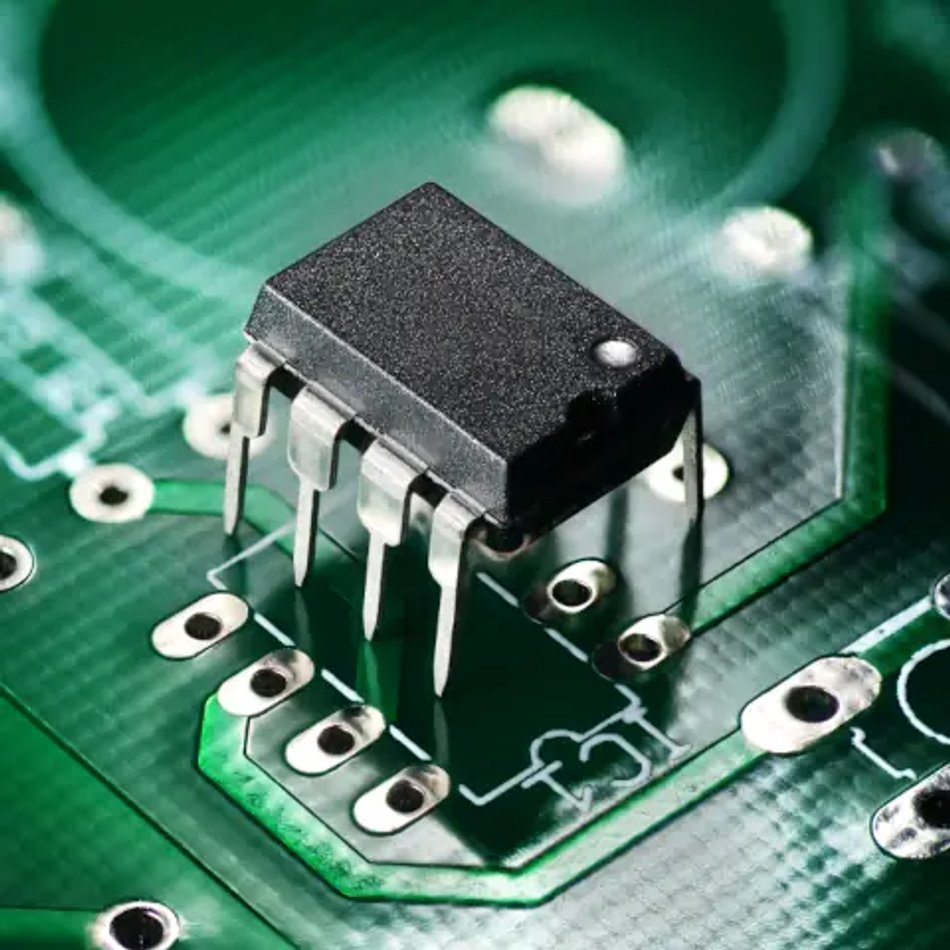

Soldering is the primary technique used within electronics manufacturing to electrically attach components to a printed circuit board (PCB). Soldering involves melting metal conductive material across masked metal pads. This forms electrical connections between the PCB and components called solder joints.

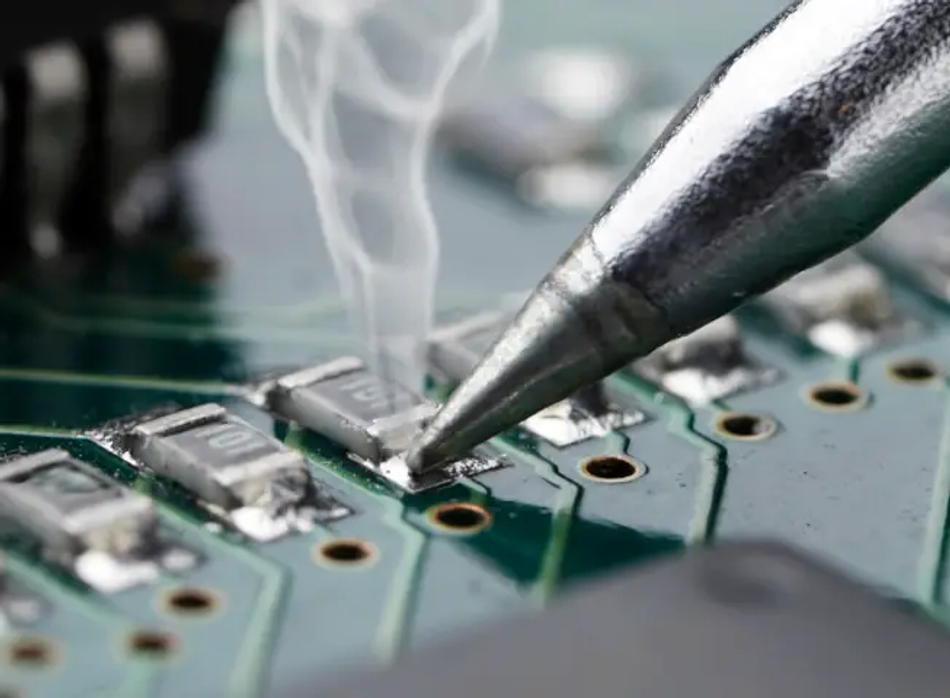

The soldering process requires a special type of agent called flux. The physical properties of solder flux can vary significantly from type to type. Flux removes oxides that form as metal gets exposed to air; oxides prevent the formation of good solder joints between the two oxidized metals.

Flux acts as a chemical compound to clean away oxidation from the component metal pins and the PCB solder pads before soldering. Without this proper flux cleaning, the solder won’t properly adhere to the component or the PCB, and a bad solder joint may result. Flux also prevents corrosion between the two metal surfaces joined together by solder application.

What Does Solder Flux Do?

Flux is critical in the creation of solder joint formation. Inherent in the soldering process are metallic impurities from the solder and the PCB fabrication processes. Flux removes these impurities from the PCB soldering surface and acts as a cleaning agent to remove oxides from the exposed metal surfaces.

After cleaning, flux presents a clean surface for a high-integrity solder joint. But once completing the soldering process, the residue must get removed through a final cleaning step. This is dependent upon the type of flux used.

Flux is a mixture of an activating chemical and a base material. It is the activator that removes oxides from metal and promotes better solder wetting. Depending upon the final system use application, different types of flux types may lend to a more successful manufacturing outcome.

Flux Application Methods

Flux is often applied in one of these three methods. Each category has different chemical properties based upon component and board soldering requirements.

- Wave Soldering: Wave solder flux composition includes many solvents. Flux gets sprayed onto the PCB before the solder wave. The flux cleans the components and removes oxidation. Depending upon the prior manufacturing steps, the PCB may need pre-cleaning.

- Solder Reflow: Solder paste screened onto the PCB only targets the intended metal pads for connection to components. The paste holds the parts in place for a short duration until the oven heat causes the solder paste to reflow and adheres between the PCB and the component leads. Solder reflow cleans metal surfaces while the sticky flux prevents more oxidation. This type of paste flux contains additives to improve solder flow as it melts.

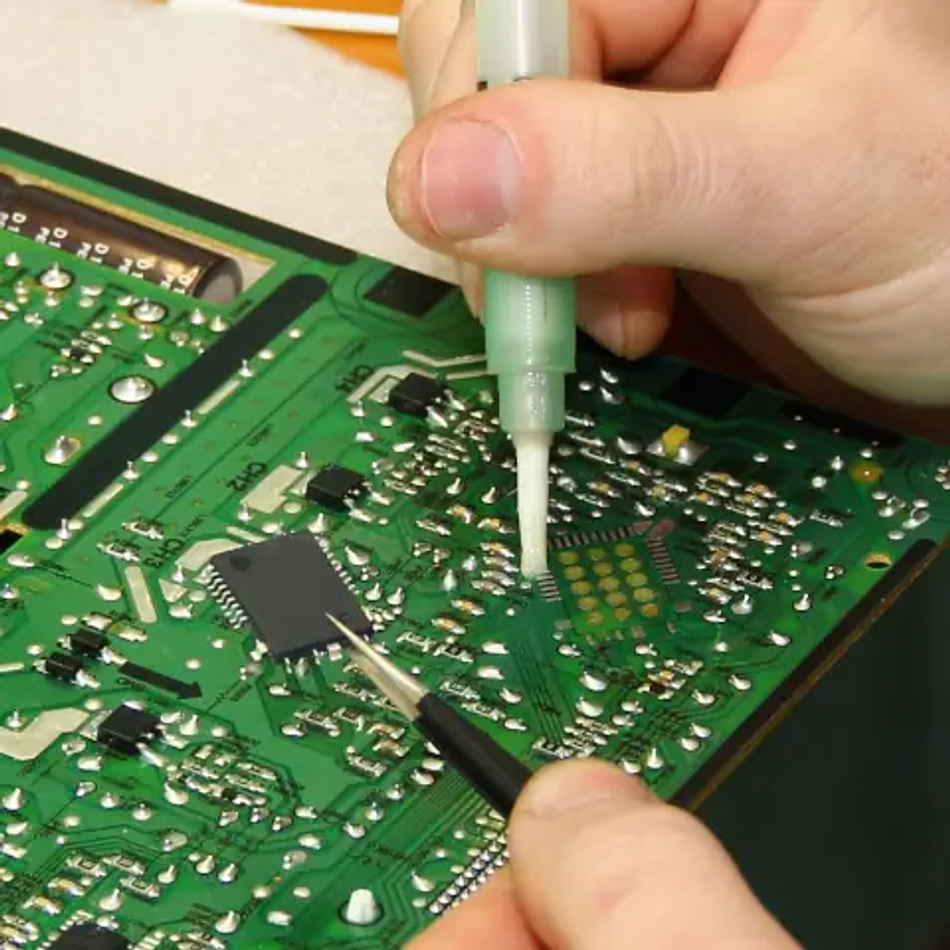

- Selective Solder: In this case, the flux targets specific areas of the PCB through a spray application or a precise drop jet process.

Cleaning Different Flux Types

Fluxes can have corrosive properties; if residue remains, it can affect board performance months or years later. Don’t forget to clean the solder flux off circuit boards.

There are three primary flux types that have different manufacturing processes and cleaning requirements:

- Rosin-Based: This flux gets cleaned off the finished PCB with specific chemical solvents that often involve fluorocarbons. Most countries have restrictions on how to use this type of flux and the disposal of its chemical byproducts. As such, this older flux type is often rejected for either of the more favorable options.

- Water-Soluble: There are several cleaning agents that are more environmentally friendly that can be used for water-soluble fluxes. These options include deionized water and simple detergents.

- No-clean: No-clean fluxes need little to no cleaning after application. Instead, cleaning is more to improve appearance than to prevent imperfections, as residue rarely leads to any contamination. But sensitive electronic and optical inspection equipment can experience some failures, and no-clean fluxes can interfere with testing and conformal coating. Thus, cleaning is still recommended.

All three of these methods need tight process controls to make sure that the flux works as intended without compromising soldering joint integrity. If not properly controlled, heated solvents have the potential to outgas and form a void within a solder joint.

Another quality problem could involve molten solder splattered onto unintended areas of the board that should get masked from solder. You can read more about solder mask in our article about SMD vs NSMD.

Choosing the right solder flux will depend upon your application, customer use, and the complexity of the component layout. By working with your CM during the design process, they can help guide you in the best solder flux manufacturing processes for your solution. MacroFab offers only no-clean and water-soluble fluxes.

Conclusion

Selecting a CM that follows your guidance on soldering processes is important. Not only will environmental policies in the country of origin impact your decisions, but also your customers will have an impact. Strict requirements imposed by some customers on the solder application and cleaning methods of flux will dictate manufacturing compliance. In addition, economic regions such as the European Union have banned the use of lead within solder and flux for all new electronics solutions.

Ready to Get Started?

Build from anywhere, anytime, with MacroFab