Understanding Conformal Coating vs Potting or Encapsulation

Conformal coating protects from damage caused by fungus, moisture, salt spray, or corrosion.

Conformal coating and encapsulation provide different levels of protection.

This article was first published on

macrofab.comUnderstanding Conformal Coating Vs. Potting/ Encapsulation

The manufacturing of PCBAs increasingly requires conformal coating and potting/encapsulation. The world’s technological advancements enable PCB assemblies to find their way into an expanding number of products in a wide range of industries. Occasionally, these products need extra protection to shield them from external contamination while preserving their original design and functionality.

Designers can achieve this result with conformal coatings or potting and encapsulation resins. Aside from providing chemical and thermal resistance to boards, both organic polymer substances also deliver electrical insulation. In spite of this, they differ significantly and shouldn’t be confused with each other. Here is a quick overview of conformal coating vs. potting vs. encapsulation, as well as their best uses.

Conformal Coating vs. Potting vs. Encapsulation – What’s the Difference?

The conformal coating and potting or encapsulation of PCBAs provide different levels of protection.

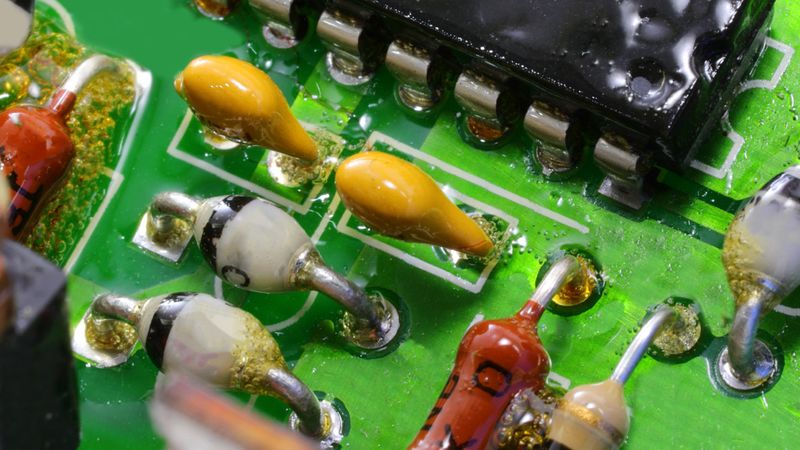

A thick resin is used to encapsulate electronic components. Resin provides protection from physical shock and chemical exposure. This step involves mixing the resin with a hardener before applying it to the board. When the crosslinked polymer dries, it obscures the component underneath.

Potting is sometimes confused with encapsulation, but the two processes are actually different. During potting, a case or shell is created, and resin is poured over it to completely encase the component. The resin-filled pot becomes part of the final product. Often, potting protects sensitive components against moisture and water damage. Furthermore, it can act as a visual and physical barrier that prevents IP theft and tampering.

A conformal coating provides a nonconductive dielectric protective layer. While this thin, lightweight coating has little to no structural effect on the PCBA, it protects it from damage caused by fungus, moisture, salt spray, or corrosion. A conformal coating is most often applied with a brush or spray.

The Best Way to Protect Your PCBA

If you have a variety of options at your disposal, how do you decide which is the best one for your application? To begin, you should consider the environmental factors that will affect your assembly, such as

- Chemical exposure: Coatings and resin both provide excellent protection from chemical exposure.

- Mechanical stress: Resin provides a thick layer of protection against physical damage in environments where components may be abraded or scratched.

- Moisture from water, humidity, etc: Conformal coating is a cost-effective method of preventing water infiltration. Water resistance varies from coating to coating.

- Physical shock: Resin spreads the impact over the entire material, reducing or eliminating damage to underlying parts.

- Temperature extremes: Extreme temperatures require additional consideration, especially when selecting resins. A special type of epoxy compound designed for aggressive environments exists.

Although encapsulation and potting provide protection from extreme environments, coatings offer more flexibility. With their thin application methods, conformal coatings can last for a long time and do not add extra weight or stress, as resin coatings do. Conformal coating often provides a secondary level of protection below the surface of an external housing. This partnership results in more effective risk management while maintaining board workability.

How to Apply a Conformal Coating

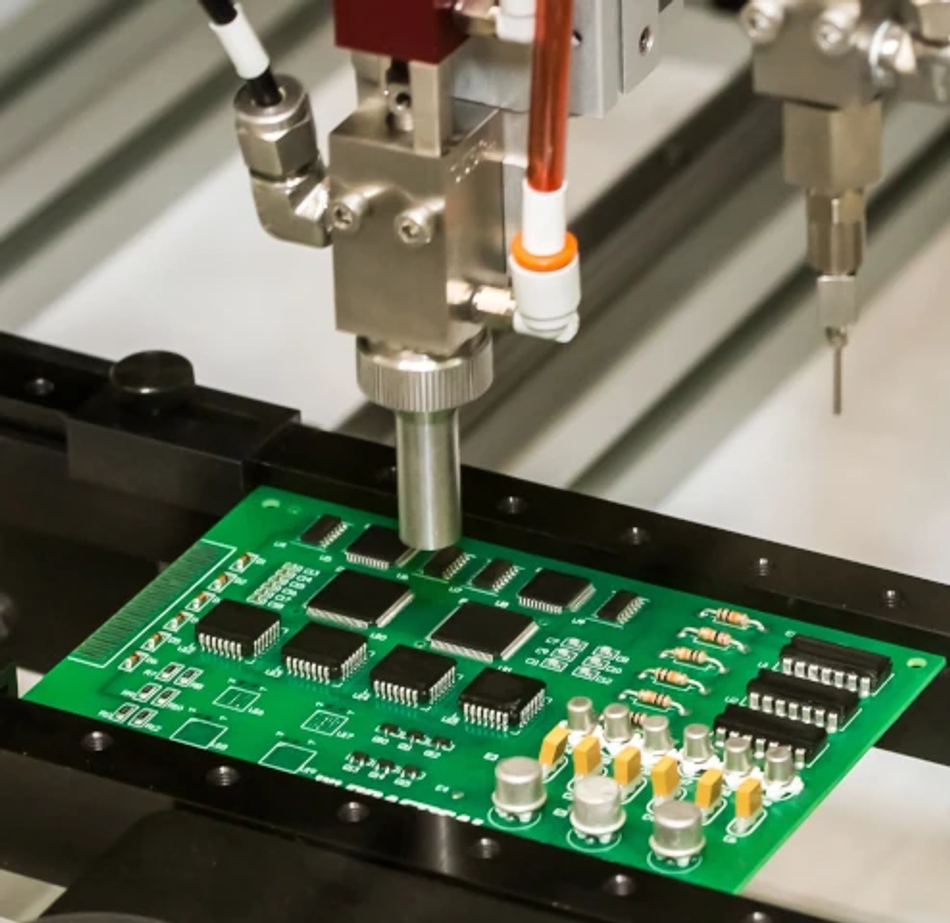

It is possible to apply conformal coatings in several different ways. This is determined by production yield and includes

- Dip Coating: In dip coating, the PCB or components get immersed in the coating solution. It allows for a full application, but issues may arise during drying.

- Brush Coating: Wet coating gets applied piece by piece with a brush. When misapplied, brush coating can lead to unsatisfactory performance results.

- Spray Coating: Spray coatings can be applied manually or by machines. In addition to its extreme accuracy, automatic spraying facilitates high-volume production due to its highly repetitive nature.

Final Considerations

Consider your vendor’s capabilities, your product needs, and any regulatory requirements that may apply to your project before deciding whether to coat or encapsulate. The Montreal Protocol restricts some chemicals once used in conformal coating formulations as ozone-depleting chemicals, so make sure your CM understands these limitations (especially if they are located in a country with fewer environmental restrictions.)

Among the conformal coating types and methods offered by MacroFab are acrylic, silicone, and polyurethane. As per industry standards, we conduct quality control under UV light and add a UV tracer to our conformal coatings.

Ready to Get Started?

Build from anywhere, anytime, with MacroFab.