Tagged with

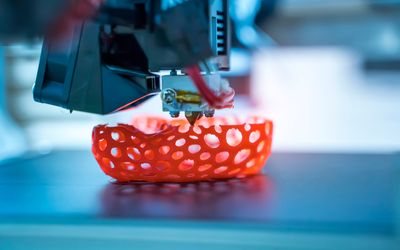

additive manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

FACTUREE – The Online Manufacturer

Manufacturing | Procurement

The digital all-in-one solution for effortless procurement of custom parts

12 Posts

View more

Latest Posts

Harnessing the potential of micro precision: how Electroformed micro nozzle plates empower applications across industries

The world of precision technology is constantly evolving, and one of the innovations that have gained significant attention in recent years is the development of micro-fabricated metal nozzle plates. These tiny, intricate components are revolutionizing industries across the board, with various applications in fields like Inkjet Printing, Medical, and Flow Control. In this article, we'll explore the key features of these nozzle plates, their applications, and how they empower important industry applications.

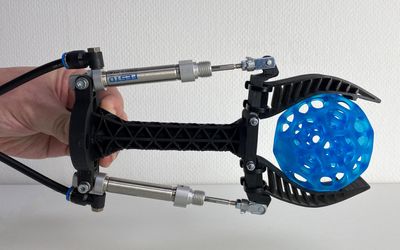

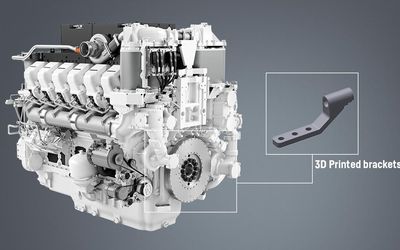

While industries like aerospace and automotive have been using additive manufacturing technologies for many years, the marine sector has recently picked up the pace of adoption thanks to the benefits provided by Large Format Additive Manufacturing. Companies like yacht and ship-builders are quickly speeding up the introduction of large parts manufactured with technologies like Caracol's Heron AM.

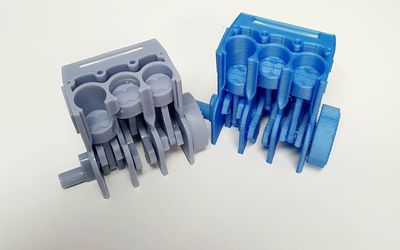

The military and defense sectors are undergoing an unprecedented transformation as military bases around the world adopt 3D scanning and additive manufacturing technologies for a wide range of applications. That includes maintenance, repair, and overhaul (MRO) processes, damage assessments and reverse engineering of parts, to name a few.