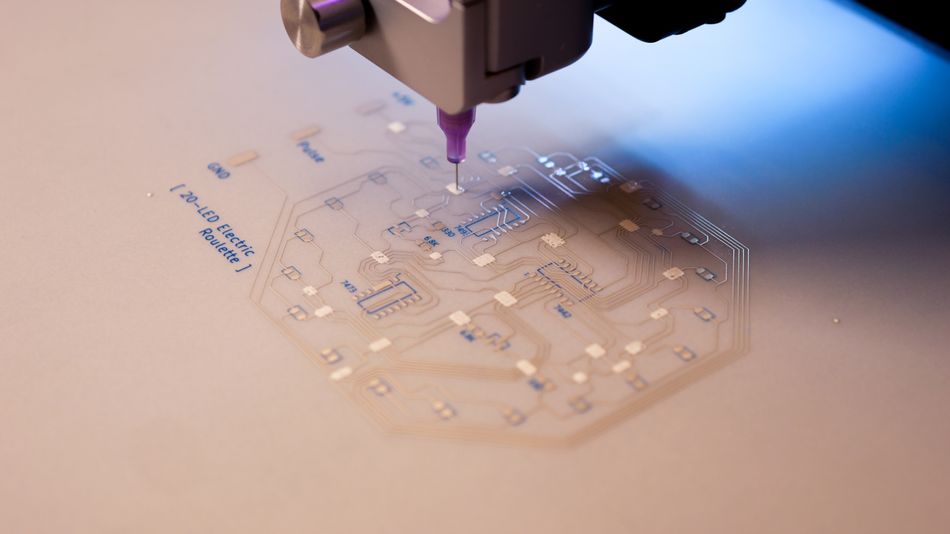

High-Resolution Electronics Prototyping: Pushing the Limits with Closed-Loop Dispensing Systems

Discover how NOVA’s Smart Dispenser module unlocks consistent and high-precision trace printing for a range of ink viscosities.

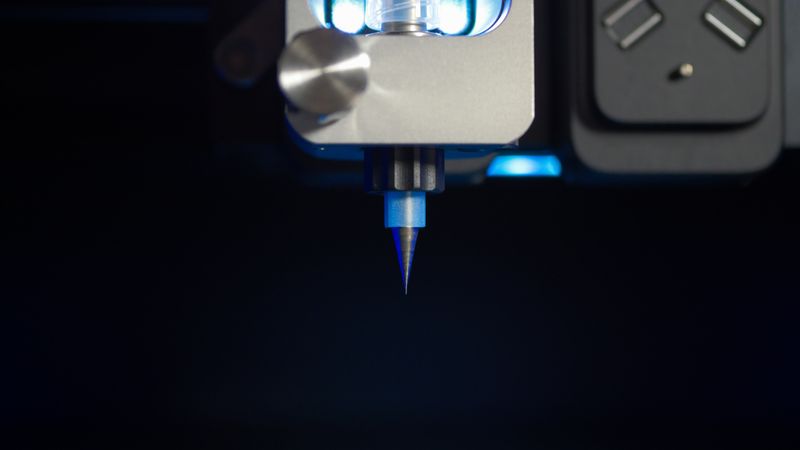

Precision nozzle on NOVA’s Smart Dispenser

In recent years, the process for developing electronics has transformed significantly due to the rise in electronic printing technologies. Compared to more conventional electronic production methods like physical vapor deposition (PVD) and etching, additive printing technologies such as direct ink writing (DIW) have ushered in a more agile and cost-effective way to design and prototype cutting-edge electronic devices, including flexible electronics and biosensors.

Not only that, advanced printing hardware, like Voltera’s NOVA materials dispensing system, is unlocking unprecedented capabilities in terms of complex and highly intricate circuits, which offer enhanced functionality without significantly increasing the cost or complexity of the production process. These benefits are in large part thanks to precision fluid dispensing, a system that facilitates the controlled deposition of conductive inks in micro amounts onto a substrate.

In this article, we will explore how closed-loop precision fluid dispensing systems, such as the Smart Dispenser integrated in Voltera’s NOVA platform, are playing a central role in the development of advanced electronics and are opening up greater material possibilities for future electronic devices.

Smart Dispenser: unlocking precision with closed-loop control

Voltera’s NOVA is a modular materials dispensing platform capable of printing a wide range of functional materials (conductive, dielectric, adhesives, luminescent) onto an equally diverse array of substrates, from rigid PCBs to flexible materials like PET, TPU, polymers, and paper. The system, used for the rapid development and prototyping of electronic devices, requires no tooling and minimizes material waste, resulting in 90% faster iteration times and 96% reduced material costs.

One of the key technologies behind NOVA’s versatility and precision is the Smart Dispenser, a self-contained dispensing module for ink and paste materials. In short, it is the Smart Dispenser that makes it possible to create high-resolution traces using virtually any screen printable ink (from 1,000 to 1,000,000 cps).

Depending on the viscosity of the ink used, the Smart Dispenser is able to print traces down to 100 μm in width with incredible consistency thanks to a closed-loop pressure feedback system. This system relies on an advanced pressure sensor, which monitors both the dispensing pressure and ink flow rate, as well as a new dispensing algorithm and automatic fluid level detection.

In addition to the Smart Dispenser’s closed-loop pressure feedback, the dispensing module integrates a heater, which enables users to control the temperature of the printing material. Maintaining an optimal temperature throughout the printing process is key to ensuring a stable material viscosity, which in turn results in more consistent trace widths.

Voltera has found that a temperature of 35°C (95°F) is ideal, striking a balance between keeping a stable material temperature—even with ambient temperature fluctuations and passive heating from the system’s electronics—and maintaining the ink’s properties, which could be affected by a higher temperature.[1] Other knock-on benefits of the dispenser’s heating function include minimized leakage (as a result of creating a negative pressure inside the material cartridge) and faster printing since cartridges do not need to be re-pressurized throughout the printing process.

Overall, NOVA’s Smart Dispenser and its closed-loop pressure feedback give users the ability to confidently work with a wide range of conductive inks and pastes while benefiting from rapid printing speeds and consistent print quality. From a user’s perspective, the Smart Dispenser is also adaptable, allowing for rapid material changes for multi-material prints, and can be used with various precision dispensing tips (like Nordson EFD 5CC syringe barrels and other standard Luer lock nozzles).

Integrating the NOVA into an electronics prototyping workflow

Just as users can easily swap material cartridges in the Smart Dispenser module, the entire NOVA platform is designed for ease of use. Intended for materials testing and flexible hybrid electronics R&D, rapid prototyping, and small-volume production, Voltera’s NOVA dispensing platform is remarkably simple to install, enabling users to start printing shortly after unboxing and seamlessly transform their materials and electronics development workflow.

Setting up NOVA only takes minutes. Simply unbox NOVA’s components, connect it to power and Wi-Fi via the included USB dongle, and then log into the browser-based interface to finish the guided set-up process.[2] Additionally, NOVA can also be used in offline mode for those wanting to protect their IP.

Initiating the printing process is equally seamless thanks to a semi-automated calibration procedure and simple material loading with the Smart Dispenser. NOVA’s calibration process also includes test patterns, which users can check and approve remotely before the printing begins. To adjust print settings, users simply have to indicate what needs improvement (i.e. more or less pressure is needed, or changing when pressure is increased or decreased along trace starts and stops) and NOVA’s software will automatically apply the new settings. Once the user is satisfied with the calibration test, the real printing can begin. With NOVA, you only need to calibrate yourtheir materials once as it allows you to save the material profile for future use.

A new software feature, Plan, also enhances the user experience and control over output, allowing for multi-material printing of up to four stack-up layers, as well as making it possible to visualize and edit print jobs in a single workflow. Moreover, Plan offers an upgraded user experience in terms of minimizing print setup times and reducing the risk of failed prints by identifying possible errors in the planning stage.

Researchers leverage NOVA for GI-monitoring device

Voltera’s NOVA has been eagerly adopted by a number of research labs for a range of applications, including the development of bioelectronics, flexible displays and PCBs, materials research and more. The platform’s ease of use and material versatility have also enabled researchers to explore the development of new and innovative materials for printed electronics, while advanced functions like the Smart Dispenser’s closed-loop pressure feedback and Plan software have given users access to professional, highly consistent results even at the prototyping stage.

NOVA was recently used by a research team out of the University of Southern California who were developing an ingestible electronic device to better monitor gas in the gastrointestinal (GI) tract for the diagnosis and monitoring of IBS, inflammatory bowel disease and other GI issues. NOVA was used to create wearable bend sensors to help locate the electronic pill inside the body (the pill itself is made from a PCB encapsulated in a 3D printed shell made from a biocompatible medical-grade resin). The bend sensors were made using stretchable carbon and silver inks on a PET substrate. According to the team’s research paper, published in Cell Reports Physical Science, NOVA offered them “high precision, reproducibility, and on-the-fly design modification capability”, all important factors when developing the non-invasive biomedical device.[3]

Transform your electronics prototyping

Overall, Voltera’s NOVA platform and Smart Dispenser module give researchers and electronic product developers the means to rapidly and cost-efficiently test materials and create circuits and electronic devices with a high level of quality and consistency. This unprecedented capability opens the doors to the development of new and potentially game-changing devices, such as ingestible biosensors for health monitoring.

References

[1] Why do we heat the Smart Dispenser? [Internet]. Voltera, 2024. https://docs.voltera.io/nova/learn-more/why-do-we-heat-the-smart-dispenser

[2] Voltera. Voltera NOVA: Unboxing and First Time Setup [Internet]. Youtube, August 17, 2023. https://www.youtube.com/watch?v=dcAq5-zZj_Y

[3] Abdigazy A, Arfan M, Shao J, Islam MS, Hassan MF, Khan Y. 3D gas mapping in the gut with AI-enabled ingestible and wearable electronics. Cell Reports Physical Science. 2024 Jul 17;5(7).