Dry Multimaterial Printing Technology: Unraveling New Realm of Possibilities in Printed Electronics

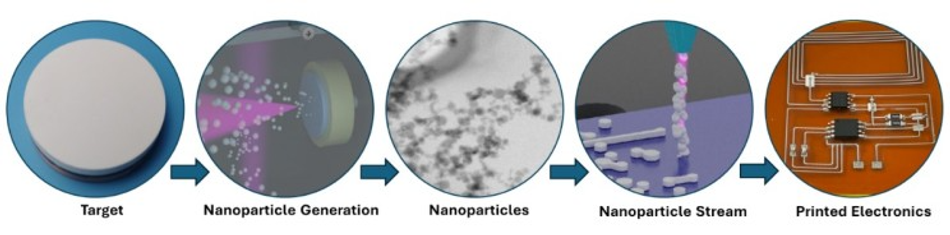

Multi-material printing without inks? The technology’s on-demand and in-situ nanoparticle generation and real-time sintering capability allow the printing of various electronics and functional devices with pure, multifunctional, hybrid materials printing - without inks and with bulk properties!

This article was first published on

www.techblick.comAuthor: Masoud Mahjouri-Samani, PhD | NanoPrintek | info@nanoprintek.com

Modern technology and the move toward the Internet of Things have escalated the demand for innovative and efficient printing techniques, particularly in electronics and functional devices. Traditional ink-based printing methods have long been the standard, but now NanoPrintek’s dry multimaterial printing technology has emerged as a disruptive alternative, offering numerous advantages over its ink-based counterparts. The technology’s on-demand and in-situ nanoparticle generation and real-time sintering capability allow the printing of various electronics and functional devices with pure, multifunctional, hybrid materials printing. This thus opens the path to electronics printing and other applications ranging from energy and health to sensing devices.

Minimize imageEdit imageDelete image

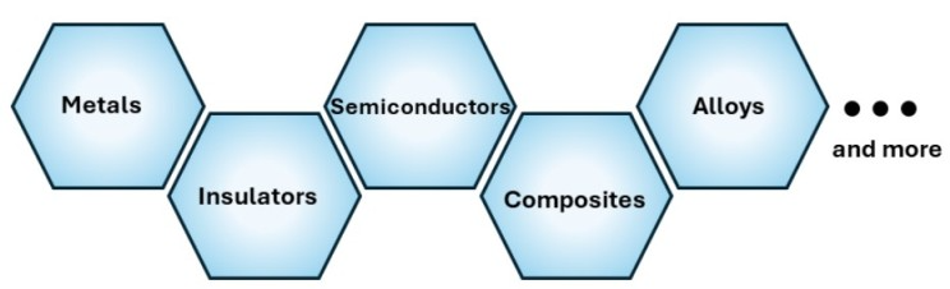

Unveiling a Universe of Materials Beyond the Limitations of Ink: Traditional inks can be restrictive regarding the materials they can accommodate. Dry printing, on the other hand, opens doors to a wider range of possibilities. From semiconductors and conductors to insulators and nanocomposites, dry printing can handle a broader spectrum of functional materials rapidly, enabling the creation of more advanced and innovative functional devices.

Minimize imageEdit imageDelete image

Environmental Friendliness: Ink-based printing often necessitates complex ink formulations, storage, disposal, and cleaning procedures. Solvents and other hazardous materials can pose environmental and health risks. Dry printing, however, bypasses these concerns entirely. By utilizing solid targets as a source for on-demand and in-situ pure nanoparticle generation, dry printing eliminates the need for harmful solvents and additives, leading to a cleaner, more sustainable, and environmentally sustainable manufacturing process.

Minimize imageEdit imageDelete image

Cost Efficiency: Dry printing technology significantly reduces production costs compared to traditional ink-based techniques. By eliminating the need for timely and costly ink formulation processes as well as consumables like inks and solvents and minimizing waste and downtime associated with cleaning, dry printing offers a more economical solution, leading to tens of thousands of dollars in savings per year.

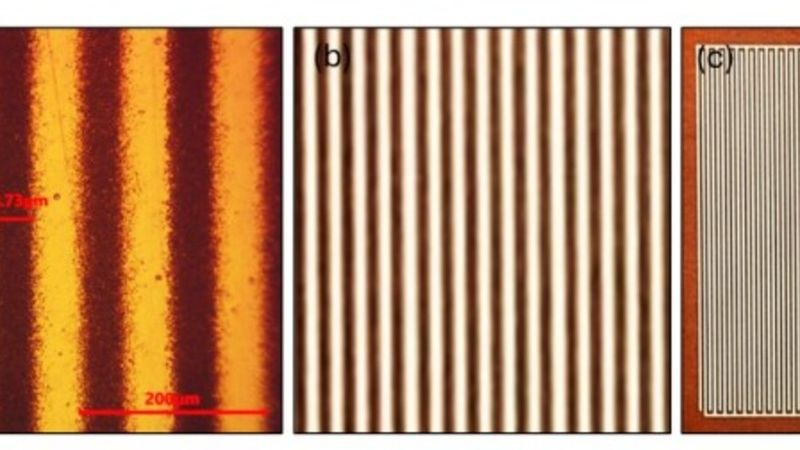

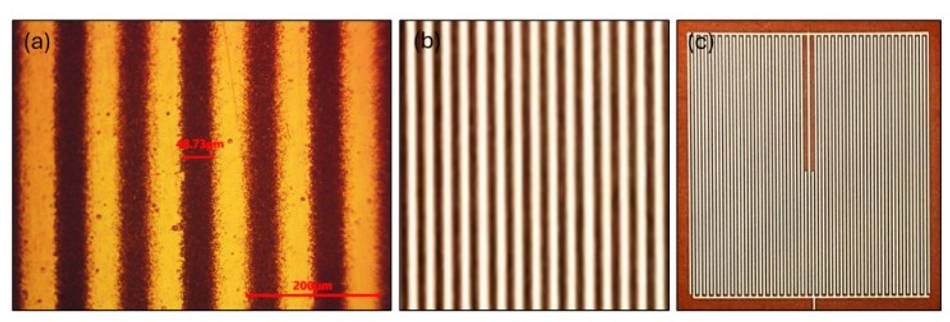

Potential Precision and Resolution Enhancement: Due to the nanoscale size and purity of the dry nanoparticles, dry printing enables higher precision and resolution in the deposition of electronic materials. This opens the possibility of creating intricate circuit patterns and fine features, leading to improved performance and reliability of electronic devices.

Minimize imageEdit imageDelete image

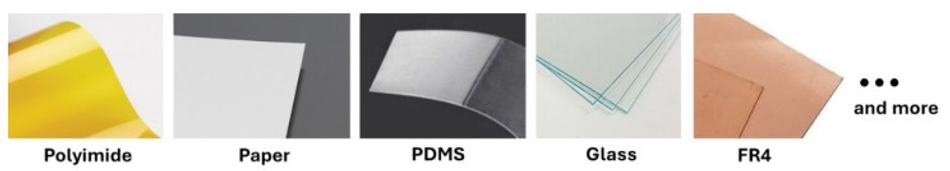

Compatibility with Diverse Substrates: Unlike ink-based printing, which may have limitations in terms of substrate compatibility, dry printing offers greater flexibility. It can be used on a wide range of substrates, including flexible materials like plastics and paper, as well as rigid surfaces like glass, ceramics, and even FR4 substrates, expanding the possibilities for product design and innovation.

Minimize imageEdit imageDelete image

Improved Durability and Longevity: The materials deposited through dry printing electronics often exhibit superior durability and longevity compared to those applied using ink-based methods. This is due to the lack of surfactant and contaminations during the real-time sintering process, which allows better particle-particle fusion and a cleaner interface with the substrate. This results in electronic devices that are more resistant to wear and environmental factors, prolonging their lifespan and enhancing overall performance.

Versatility in Applications: Dry printing electronics offers versatility in its applications across various industries, including consumer electronics, automotive, healthcare, and beyond. Whether manufacturing flexible electronics, RFID tags, sensors, energy devices, or smart packaging, this technology can adapt to diverse needs and requirements.

In conclusion, the advantages of dry printing electronics over ink-based techniques are indisputable. From cost efficiency and environmental friendliness to enhanced precision and versatility, this disruptive technology is reshaping the landscape of functional devices and electronic manufacturing. As advancements continue to propel the field forward, NanoPrintek's dry printing technology promises to unlock new possibilities and drive innovation across industries.

We are Exhibiting at the Future of Electronics RESHAPED event in Boston (12 & 13 June 2024) : https://www.techblick.com/electronicsreshapedusa

Minimize imageEdit imageDelete image