Tagged with

manufacturing systems

ORGANIZATIONS. SHAPING THE INDUSTRY.

READY Robotics

Robotics & Automation

READY Robotics is a robotics software company that vastly simplifies robot ...

24 Posts

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

View more

Latest Posts

A Closer Look at Digital Twins, Virtual Factory Models that Expand the Potential of Their Real Counterpart

Smart Factories: Giving Form to Digital Transformation in the Manufacturing Industry

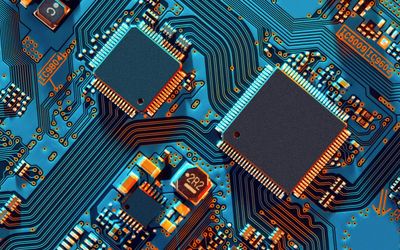

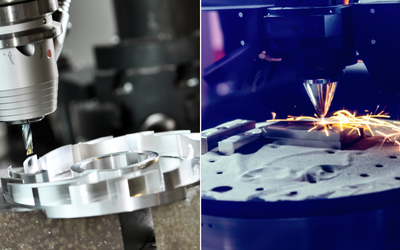

The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC materials available. Furthermore, with the introduction of computer numerical control, the process becomes more accurate, faster, and suitable for making parts with tight tolerance. How much do you know about plastic CNC machining? This article discusses the materials compatible with the process, available techniques, and other things that can help your project.

In this article, we will delve into the diverse world of CNC materials. We will provide you with a comprehensive guide to selecting the right materials for CNC machining, including a detailed list of commonly used materials. Additionally, we will touch on some lesser-known materials that you may not have considered before.

This blog comprises a collection of articles on innovation written by Hubert Martens, the CEO and founder of Salvia BioElectronics. Originally shared on LinkedIn, Martens intended to spark a conversation about innovation and introduce the innovation model he and his team developed over their careers.

The surface finish is an integral part of the CNC machining process because a lot of applications require both aesthetic and functional design. Modern industrial designers have all the right tools and checks to ensure that their designs are functional. So, CNC machining surface finishes is an area where they can cause their product to stand out from the crowd.

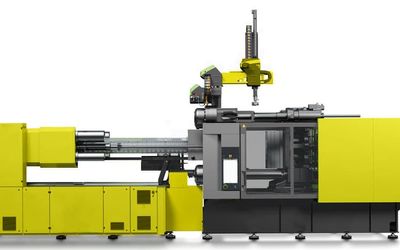

The injection molding cost is a common focus of plastic product manufacturers who use the process. It is an agglomeration of different factors and elements, and understanding such factors and elements plays a critical role in optimizing the cost of any project. As a result, this article breakdown everything you need to know about how much injection molding cost and how you can optimize it for your project.

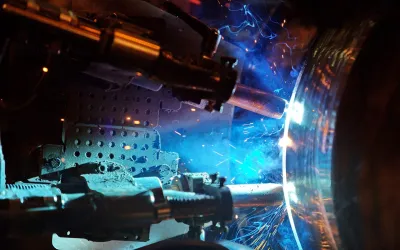

Submerged arc welding is a standard industrial process wherein an arc is formed between a workpiece and an electrode. It was invented in 1935 by the E. O. Paton Electric Welding Institute in Kyiv, Ukraine as a driving force behind the Second World War. One of the most notable applications of this invention is the T34 military tank.

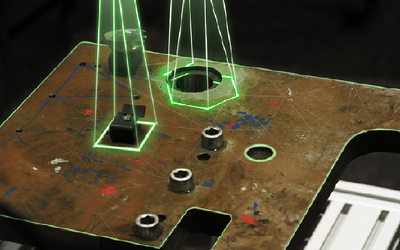

First article inspection (FAI) is a crucial step in the manufacturing process. The quality control (QC) team needs to optimize this phase of inspection in order to limit the back and forth between conception and fabrication. The QC team must not only correctly identify the defects, but also provide relevant data, measurements, and results for solving the identified problems.