Solve Problems by Going Back to the Start

Let’s not think about things just as they are but let’s think about things as they could be – that is the heart of problem-solving.

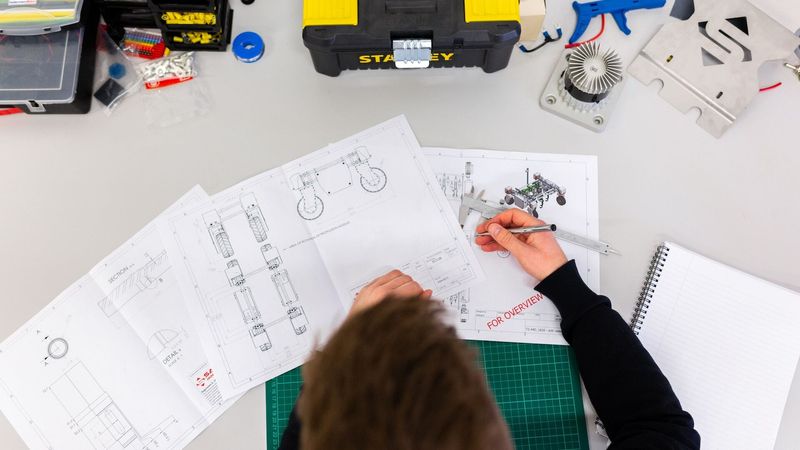

Photo by ThisisEngineering RAEng on Unsplash

The world is not short on pressing problems. And many of them will fall to us - to the engineers - to solve. This article explores, arguably, the best approach to problem-solving, including the way I applied that approach to my own company which solves a problem inherent to the world of manufacturing.

Engineering is about solving problems. And, for the most part, we’re engineers in the first place because we’re curious about things, the way they work and the way they can be improved. But that doesn’t make us perfectly diligent and dependable.

Engineers – at time of writing – are all too human and we often think we are solving problems when in fact we are just finding clever ways to live with them. Often that’s because time and resources are limited. To tear something up and start again is normally the expensive, difficult route, at least at first. But I feel strongly we should always try to consider what something might look like if we went back to the start and approached it as if for the first time.

There’s an important distinction between completely fixing something and merely improving something. The latter is a kind of solution, but often it’s just delaying the inevitable, kicking the can down the road, as they say. A useful way to ensure you are solving a problem and not simply finessing it is to ask how you would approach things if you went back to the beginning. This clears your mind from the existing solutions and creates room for visualising the perfect future without constraints. Once you get there, you can start asking what else should be true for this perfect solution to be true? This gives you the requirements along with the smaller problems to solve and you can assess whether this completely new and better solution is viable or not. That new beginning, that new way of doing something, will probably be hard to get to. There will be serious barriers, not least time and cost. But in the long run the right solution will be more economical, efficient and sustainable than any easy improvements you might make to the old method.

Starting over with Fractory

My own company was created to solve a problem, one I feel acutely as an engineer because it takes up my time and energy and is expensive and distracts me from the core engineering work I would prefer to focus on. It’s the problem engineers face in procuring parts. It’s the problem they face navigating supply chains. For the wider industry it even incorporates the problem of better utilising machinery and material resources.

So, with my co-founders, we created Fractory, which automates time-consuming and difficult aspects of the manufacturing process, specifically quoting and buying as well as project management and logistics. We free engineers from the intensive work of traditional drawings because metal parts can be ordered simply by uploading CAD files to our platform. We free them from the crazy stresses of managing supply networks. And we improve things for suppliers too, for the metal fabricators themselves, by providing demand where and when there is capacity and capability to supply.

Our solution saves time and saves energy, freeing up talent and allowing people to focus on important work and perhaps allowing them to solve vital problems. Engineering time is precious and the shortage of engineers is a serious threat. So, Fractory greatly improves utilisation of the existing engineering resource.

And we really did go back to the beginning. We built a machine (our platform) for instantaneous quoting and ordering from design files, which optimises for cost and lead times. And we built an organisation (our people) to handle those orders that don’t achieve an instant quotation and to handle design complexities and supply chain intricacies where they occur. We didn’t create just a marketplace where people upload designs and companies quote for them, as this would have actually made the situation even worse for companies wasting their time on quoting. That would be an example of building on top of existing solutions. Rather, we imagined a new way, a solution for both ends - the customer and the supplier.

We wondered what a brand-new solution would look like. In fact, the goal was not just a new solution, but rather a perfect solution, something to be imagined without fear of the status quo. And that’s what the Fractory software engineers and mechanical engineers are building. And now global businesses come to us for their series and project manufacturing needs. And universities and inventors come to us for their prototyping needs. Our solution is being adopted across the manufacturing spectrum and is already making a difference.

Things as they could be

In approaching problems it’s useful to make sure we are not just thinking about things as they are, but about things as they could be. The pen is powerful, most writers would acknowledge. But someone once decided that the status quo on writing implements could be smashed and that we should create something new, something that was hugely difficult to make, that had thousands of moving parts and weighed a tonne, that would cost a lot of money and take a lot of time and that would be difficult – at first – to use. Lo and behold, the typewriter, an object currently recognisable as a crucial part of most computers.

That was quite a leap! The process to get to a working typewriter and then to settle on the famous QWERTY layout was not straightforward, surely.

Admitting there’s a problem

It would have been easy to just make do with the pen! But somebody recognised a problem and got curious about a solution. Early efforts, machines as big as cars, were perhaps dispiriting. But the search for a solution went on and soon small electric models were being churned out. (And look where it’s got us: everyone’s got a novel in them!)

Yet a great many are all too happy with things as they are. We see it with Fractory. Some engineers do not easily recognise the problem we first identified, the huge amounts of time and expense spent on procurement, spent on navigating supply chains: the problems that Fractory solves. That’s why often it is good to talk less about solutions and more about problems. Get into the problems! Recognise them! Admit to them! And then be brave and go back to the beginning. Ask yourself, what would it look like if we started again?