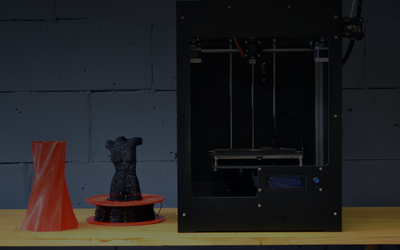

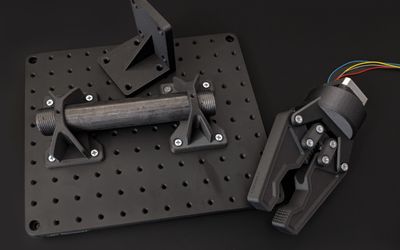

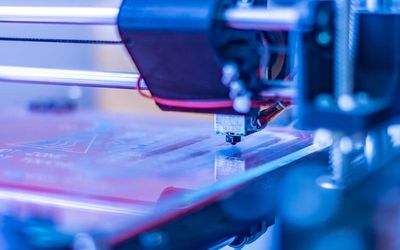

How do you choose the perfect 3D printing filament - A comprehensive overview of large scale printing materials

When it comes to FFF (Fused Filament Fabrication) 3D printing, selecting the appropriate printing material is crucial and should never be underestimated.