The Engineer's Guide to 3D Printing with Wear Resistant Plastic Materials.

A comprehensive introduction to 3D printing with wear-resistant plastics, exploring their origin, benefits, and the technologies available to print with them.

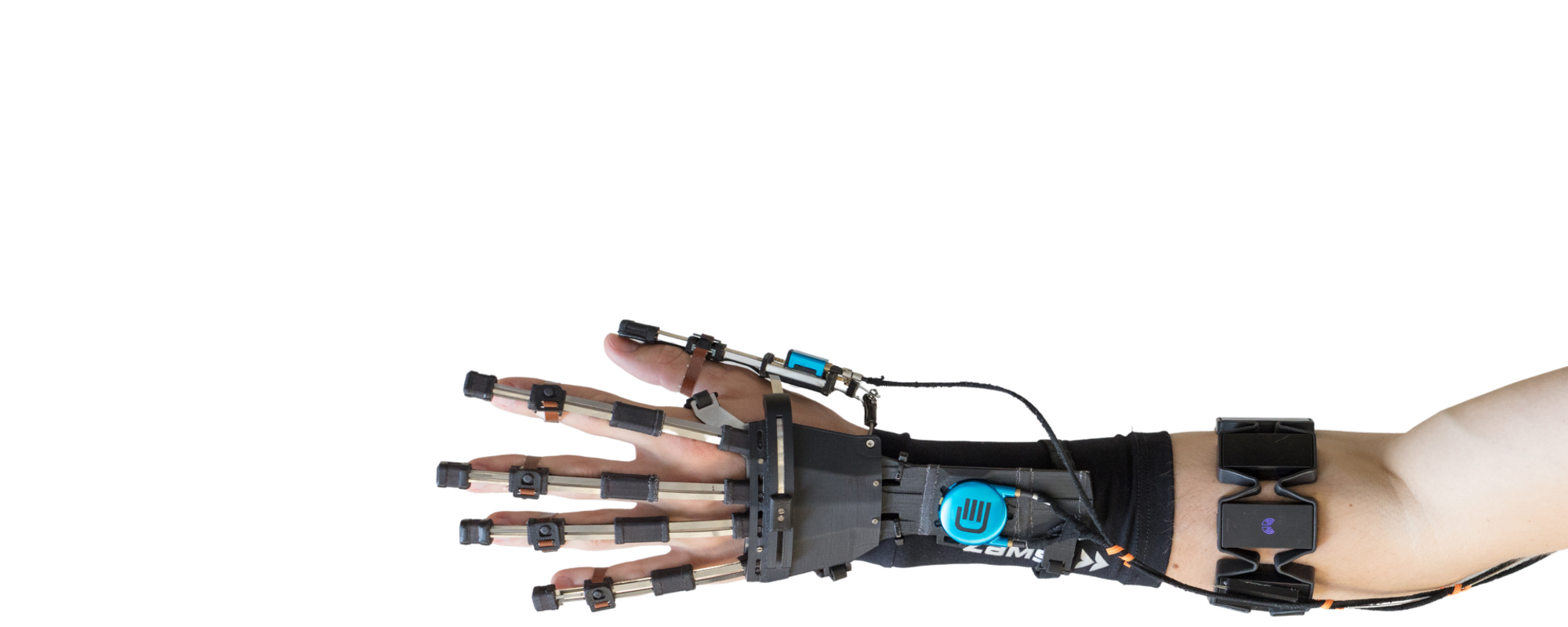

3D printing for low-friction sliding applications

In the ever-evolving landscape of engineering and manufacturing, 3D printing has emerged as a technology, promising to solve a myriad of challenges. However, not all 3D printing materials are created equal. This comprehensive guide aims to shed light on a specialized category of 3D printing materials—wear-resistant plastics.

These unique materials are not just another addition to the growing list of filaments, powders, and resins available in the market. They are engineered with a specific purpose: to excel in low-friction sliding applications. Unlike generic materials that offer broadly desirable attributes like tensile strength or flexibility, wear-resistant plastics are designed to meet a highly specific engineering need. Infused with solid lubricant additives, these materials offer unparalleled wear resistance and sliding performance, setting them apart in the additive manufacturing materials market.

Valuable engineering insights

The guide provides a comprehensive introduction to 3D printing with these wear-resistant plastics, exploring their origin, benefits, and the various technologies available for printing them. Whether you are an engineer looking for innovative solutions in prototyping and production or an industry professional seeking to understand the latest advancements in material science, this guide offers valuable insights.

In each chapter of the report, we delve into the specifics of why these materials exist, how they can be exploited for maximum advantage, and the different technologies available for printing them. From the basics to advanced applications, this guide aims to equip you with the knowledge you need to make informed decisions in the realm of 3D printing with wear-resistant plastics.

The report is sponsored by igus®, a globally recognized leader in the manufacturing of innovative motion plastics products. With a diverse range of offerings, including energy chain systems, cables, polymer bearings, and linear systems, igus® has carved a niche for itself in the industry. The hallmark of their products lies in their cost-effectiveness, durability, and versatility, making them a preferred choice across various industrial landscapes. Learn more about them here.