Be the first to know.

Get our collaborative robots (cobots) weekly email digest.

collaborative robots (cobots)

Engineers Wiki. Most Asked Questions.

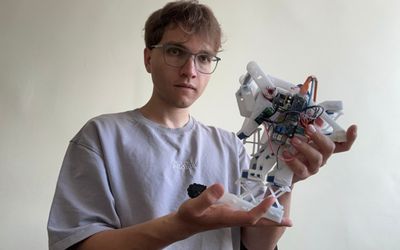

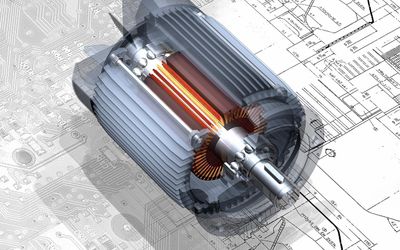

This article delves into what is a cobot, exploring its architecture, programming interfaces, control systems, safety protocols, intricate mechanics, and integration capabilities of modern cobots.

Robot Joints: An In-Depth Guide to Anatomy, Physics and Challenges in Design...

By Ravi Rao.

16 minutes read.

Cobots vs Robots: Understanding the Key Differences and Applications

By Ravi Rao.

11 minutes read.

ORGANIZATIONS. SHAPING THE INDUSTRY.

NEURA Robotics

Robotics

To handle the rising global demand, companies necessitate individualized solutions which require increasingly complex production p...

1 Post

Pickit 3D

Industrial Automation

Guide your robot with Pickit 3D vision systems. Pickit is an ambitious scal...

APEX Motion Control

Machinery Manufacturing

Automation and Robotics for Food, Bakery, Pet Food and Pharmaceuticals.