The Complete Guide to The Phase Gate Approach to Developing a Hardware Product

The phase-gate approach (PGA) is a supportive tool that guides hardware manufacturers to successfully develop innovative products, avoiding common manufacturing errors, failures, or reducing defects.

Manufacturing processes have seen an unprecedented transformation partially thanks to engineering advances, digitalization, and the increasing influence of Artificial intelligence (AI). In this industrial shift, approaches to manage product development have also seen a significant change. From the first Phase Review Process developed by NASA to the third generation of product development processes, the stage-gate or phase-gate method remains a staple approach for product development.

For matured companies, SMEs, and start-ups, effective product development is a major concern and the search for effective hardware production has not yet finished. This article examines the cycles of hardware development through the phase-gate approach.

Introduction to PGA

By following a series of well-defined phases or steps, the PGA enables the conditions for companies to take advantage of innovation while acting rapidly to capture potential new markets with the use of advanced technology and cross-team collaboration.[1] From a product idea to the final production and marketization stages, the phase-gate approach (PGA) is a supportive tool that guides hardware manufacturers to successfully develop their products, avoiding and preventing major manufacturing errors, failures, or possible defects. The PGA offers companies the possibility to manage more effectively product development by increasing quality and reliability.

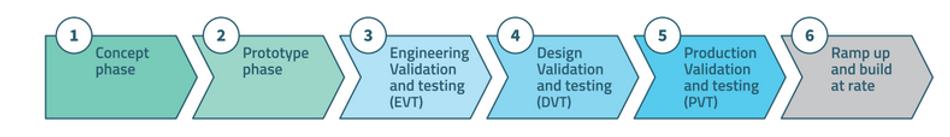

Figure 1. The KREATIZE phase-gate approach

Each of the six phases offers the possibility to improve the possible outcome of a future hardware part or a more complex product. Project management, the manufacturing of a component, a machinery part, or a specific client request can also be done following an established PGA methodology.

The PGA Journey

In a PGA, each phase is highly dependent on another. Every phase consists of elaborated tasks, including product definition, standards compliance, testing, or the integration of customer feedback (voice-of-customer). In between each phase, a gate or checking point is allocated to ensure that the right decisions are made. With these gates, each team can funnel the best possible solution and communicate them to other departments as accurately and quickly as possible.[2]

6 Steps towards advanced product development.

The model consists of 6 phases. Each phase is designed to ensure fluidity (move from phase to phase with higher accuracy and speed) and adaptability (each product requirements are unique).[2] In this section we explore the PGA step by step and present the main points to understand how the PGA is applied in product development:

Concept

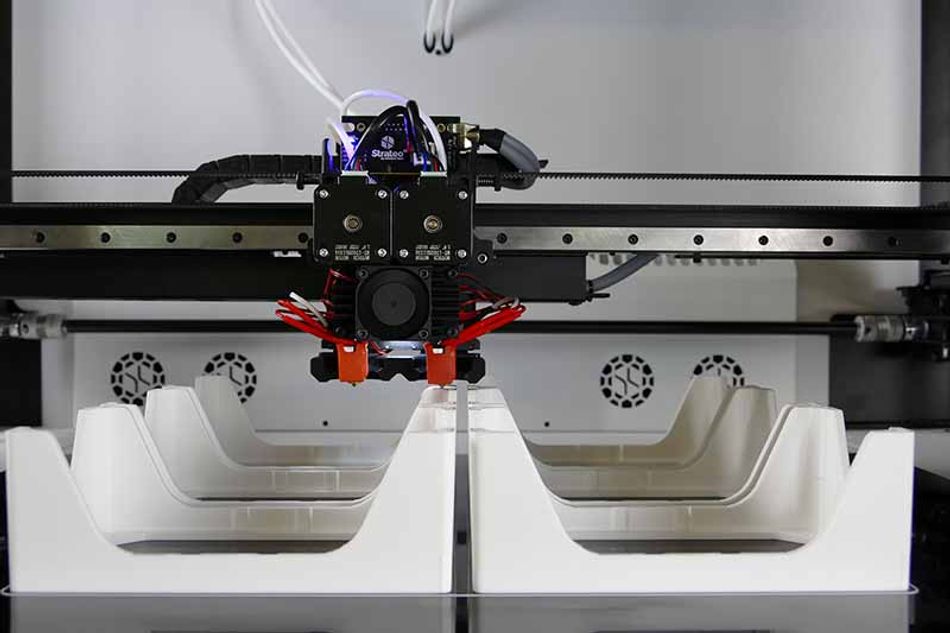

This is the first step. Engineers sketch the first product concepts, defining features such as material content, physical properties, purpose, performance, functional cycles, and design. Initial models are created using for example computer-aided design software and printing the models in 3D. Once initial designs are drafted, the proof-of-concept is decided. Several ideas are created and compared.

If you are creating fully new hardware, this phase could take several months or even years as you want to ensure your product will be good enough to satisfy clients, potential customers, and competitive markets. In the case of a singular hardware component, the process should not be so time-consuming. When form, fit (meeting requirements), and function are achieved, the concept can move to the next stage.

Prototype

Prototypes are built and technical teams start initial testing. The first idea of parts, materials, and necessary components is known. The procurement team takes the task of finding providers. The bill of materials is developed and the necessary arrangements for future testing and reliability assessments are defined. The quality assurance procedure begins.

Engineering Validation and Testing (EVT)

At this point, enough prototypes have been developed to select the one that fulfills all determined functionalities. The compatibility of different parts and components is tested and optimized in the case any interference is suspected to affect other components. If an idea of the number of products requested is known, the purchasing team can start calculations to order materials, specific components, customize equipment, and consumables.

During this stage, prototypes are built with the intended materials and the most convenient manufacturing processes. Assembly, manufacturing, maintenance, producibility, procurement, and reliability are the factors required to meet product functionality, and therefore, engineering approval.

Design Validation and Testing (DVT)

Operational units can potentially be produced. Once a set of samples with the original materials and features are provided, final testing should be executed. All product deficiencies should be corrected here. The engineering team as well as management need to coordinate with precision the details for final production. Reliability tests take place. The mass production team starts verifying yields to calculate profitability and marketing strategies. After all, teams have agreed on the product fulfilling the gate between phases. Therefore, production can move to the next stage.

Production Validation and Testing (PVT)

No more prototypes. The product selected should be ready to be provided to customers. Uncertainty of failure has been minimized or eliminated and all product functions fit the safety and quality requirements and comply with functionality. The design is validated. Production and assembly lines are set up for high volumetric production and testing at maximum velocity. The production phase begins, and the production team continues optimizing manufacturing.

Production and Selling

High volume production starts with security that all teams agreed upon the best most reliable and cost-effective decisions. Because every good company cares about quality, a random product sample is periodically selected and tested to ensure the physical characteristics of each product comply with predefined requirements. This is the so-called Ongoing-Reliability-Test (ORT). Marketing and sales have been working hard to get the product to the markets and access clients at a rapid phase. You have gone through the laborious PGA methodology.

Increasing Team Collaboration

The PGA is a complex process. To ensure the PGA fulfills its purpose, all teams should be familiar with the method. Training and willingness to cooperate are essential to create a more solid sense of mutual responsibility while sharing the know-how. The PGA helps to ensure that undesired miscommunication is avoided from the beginning of product development. Teams decide how the approach will be used to meet the client's needs, the product requirements, and maintain the company's reputation.

Therefore, the system is not performing as a rigid system, rather as a “smart system”[2] tailored to each product development. In the PGA, every team is self-managed but team leaders communicate advances, requests, errors, or other types of important information.

But like any other system, this approach also has its weaknesses. If flexibility is not allowed from the start, the process can become linear and the phase of improvement limited. Consequently, the company will not be able to adapt to increasingly rapid market demand and technological changes. On the other hand, excessive planning or flexibility could hinder the process's robustness and result in more demanding work for all teams.[3]

Four key supportive elements for a successful PGA are:

- Integrate agile methods to respond quickly to external marketspace of change [3]

- Digitalization allows faster communication, more intuitive work approaches, and receives customers' feedback at the speed of a click.

- Cloud manufacturing could omit some of the challenges of PGA methods such as long product development periods, better collaboration tools, or the creation of pay-as-you-go models.

- Move towards Industry 4.0 with the introduction of Internet of Things (IoT), Digital Twin (DT), or Artificial Intelligence (AI) [5]

Supporting Process Robustness

PGA has a big potential to increase quality and performance. From the beginning of the process, each team is in control and can test product performance with more accuracy. The quality of the product is continuously improved as prototyping becomes easier with the aid of automated manufacturing machinery. High-quality standards are followed from the start of the process. Because the product has gone continuously through rigorous evaluation and reliability testing, process robustness potentially increases[4].

Is PGA The Right Approach For Your Company?

If your company resembles isolated teams working in silos instead of cooperative structures, the PGA is not for you. German-based cloud manufacturing platform KREATIZE uses the PGA when working with clients on hardware projects understands that teamwork should be promoted in each step. This can represent a challenge for some companies, but success in implementing this approach can generate a powerful transformation in internal cooperation. As teams begin to work together, the potential for a successful product increases.

Conclusion

The speed of technological transformation is challenging businesses to respond to changing customer and market demands. With the help of methods such as the PGA, several companies can benefit by breaking down product development into well-defined phases. From concept design to manufacturing and sales, the PGA is the tool that enables product improvement throughout the entire development process.

This article is based on the whitepaper 'Developing a hardware Product: The PhaseGate Approach' produced by Kreatize, with editing by Nicolas Sarmiento Sierra. Download the full whitepaper here.

References

1. KREATIZE. (2021). Developing a hardware product: the phase-gate approach. Kreatize.

2. Cooper, R. G. (1994). Perspective third-generation new product processes. The Journal of Product Innovation Management, 11(1), 3–14. https://doi.org/10.1016/0737-6782(94)90115-5

3. Cooper, R. G., & Sommer, A. F. (2016). Agile-Stage-Gate: New idea-to-launch method for manufactured new products is faster, more responsive. Industrial Marketing Management, 59, 167–180. https://doi.org/10.1016/j.indmarman.2016.10.006

4. Cooper, R. G. (2019). The drivers of success in new-product development. Industrial Marketing Management, 76(January 2018), 36–47. https://doi.org/10.1016/j.indmarman.2018.07.005

5. Lo, C. K., Chen, C. H., & Zhong, R. Y. (2021). A review of digital twin in product design and development. Advanced Engineering Informatics, 48(March). https://doi.org/10.1016/j.aei.2021.101297