Open-Source Software for Unconstrained Design in Additive Manufacturing

Andy Gleadall, Lecturer at Loughborough University develops FullControl GCode Designer in the hope to empower people to do the impossible with scripts and slicers.

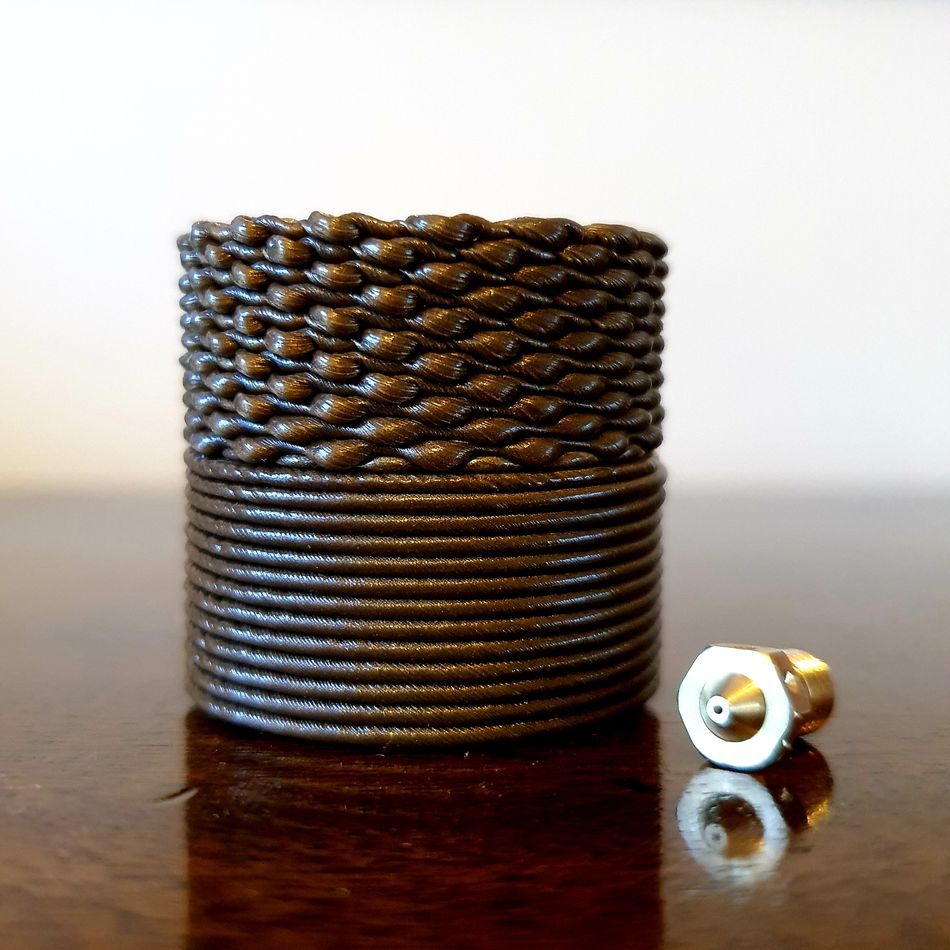

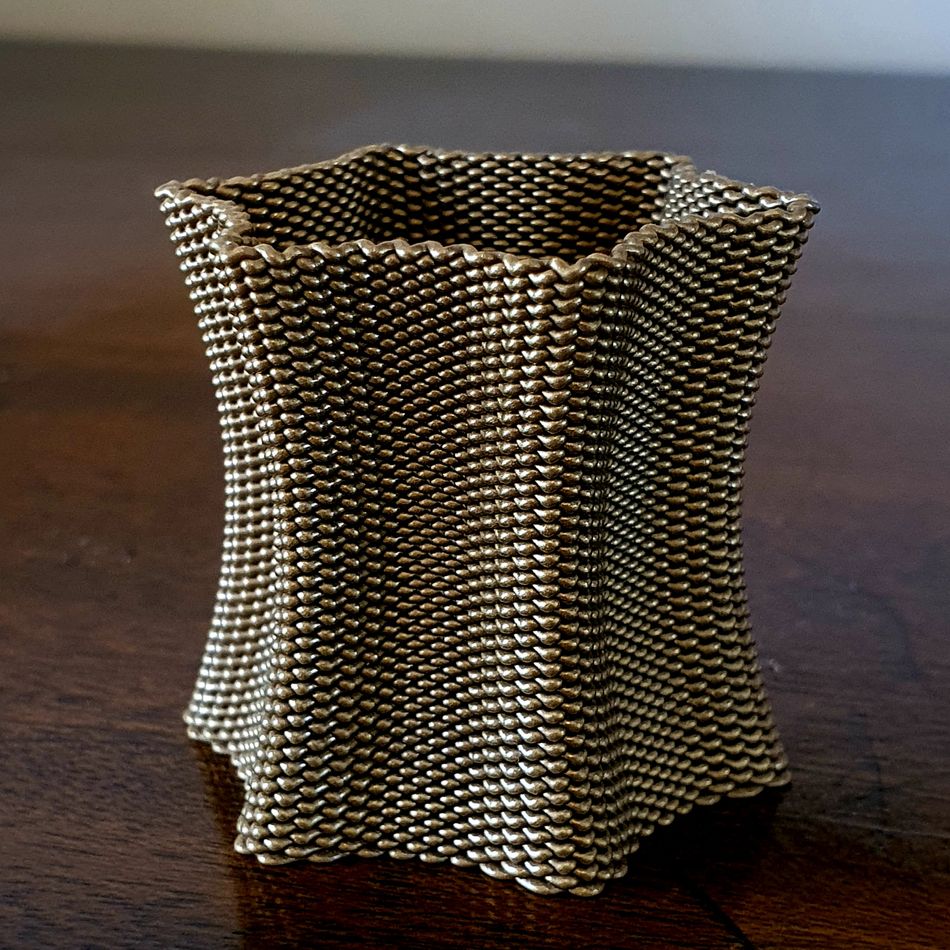

Ripple texture printed using the a simple print-path design, using a parametric FullControl design file.

FullControl GCode Designer is new open-source and free software for the unconstrained design of additive manufacturing print paths and related aspects of the manufacturing plan.

Challenge

The conventional workflow for additive manufacturing is to develop a CAD model, convert it to triangulated STL surface geometry, slice that model into layers, identify the print path for each layer, and output a manufacturing file (GCode). Each stage introduces errors and limitations.

Solution

In contrast, FullControl GCode Designer (www.fullcontrolgcode.com) turns this whole process on its head. Rather than creating a CAD model and then determining how to move a print head around to simply fill the required 3D volume, FullControl GCode Designer allows the precise print path to be designed directly. This provides unparalleled design freedom and epitomizes the concept of Design for Additive Manufacturing. It allows the designer to think “What can I produce by moving a nozzle with a controlled extrusion rate?” which can allow dramatically different structures to those seen conventionally.

Results

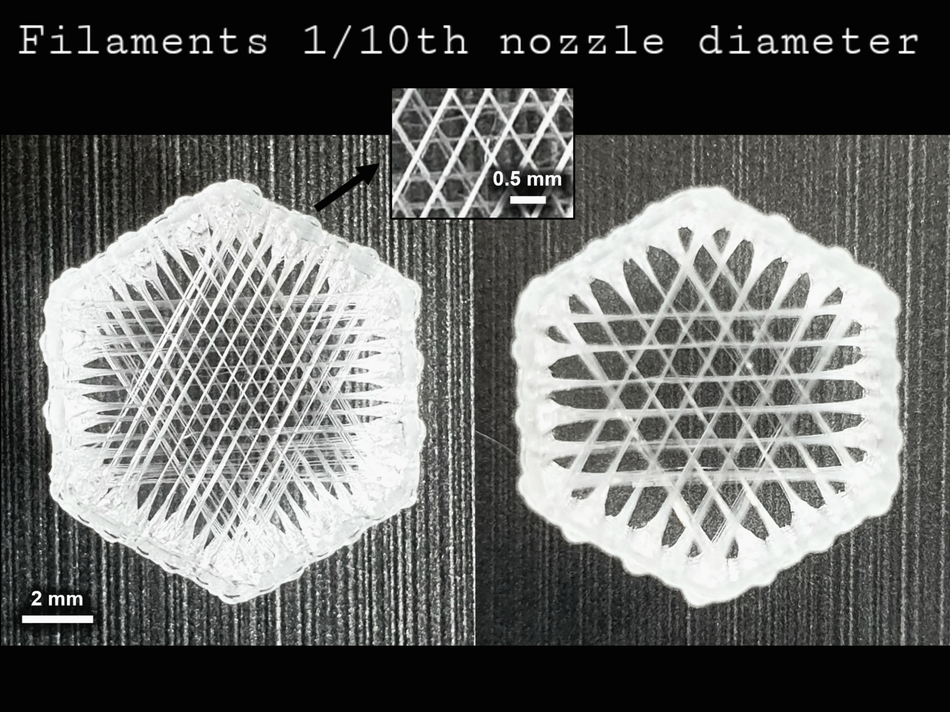

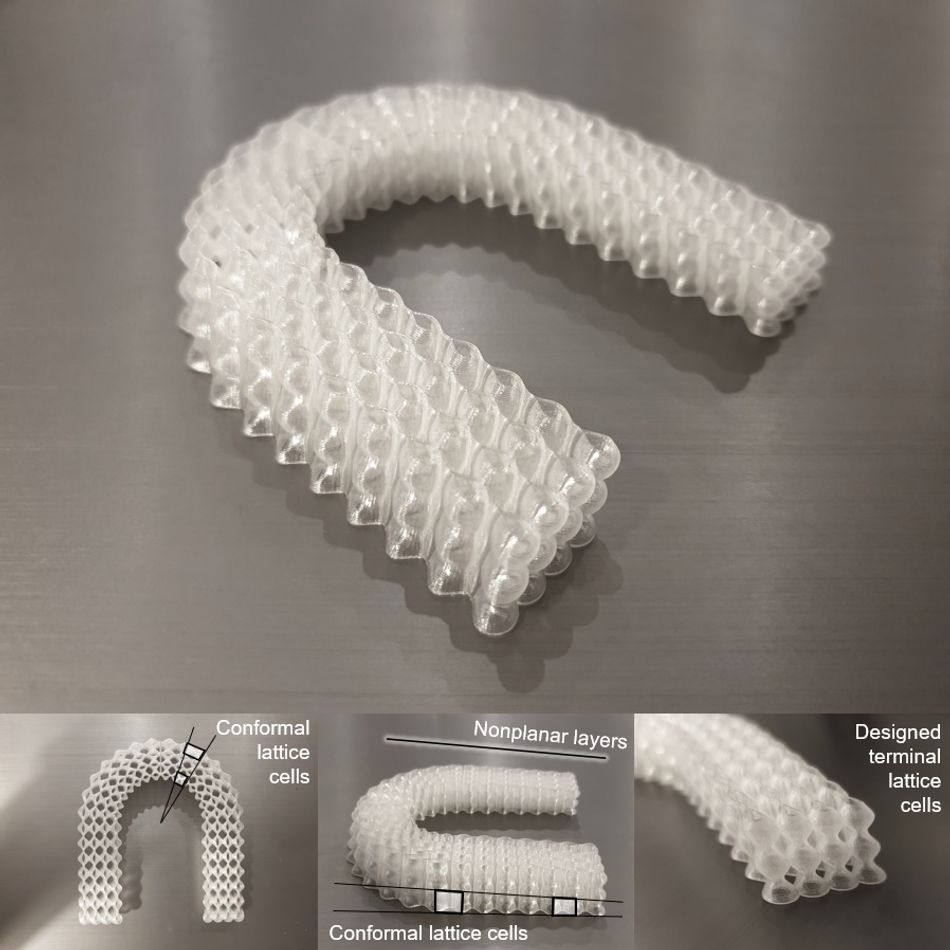

FullControl allows unlimited exploration of 3D space for printing and of the potential capabilities of 3D printers. It’s been used to print single extrusions 10x wider than the nozzle diameter and other extrusions 10x narrower than the nozzle diameter. That means a 100-fold difference in design resolution of fully dense extrusions is possible from a single system, which is entirely incomparable with conventional additive manufacturing print paths. It’s an example of how FullControl GCode Designer encourages innovative thinking beyond the general design rules, which are actually based on principles of printing with slicer software rather than the true capabilities of 3D printing hardware. Similarly, creating structures with innovative texture and porosity is possible when explicitly designing the 3D movement of the nozzle whilst extruding.

|

|

|

|

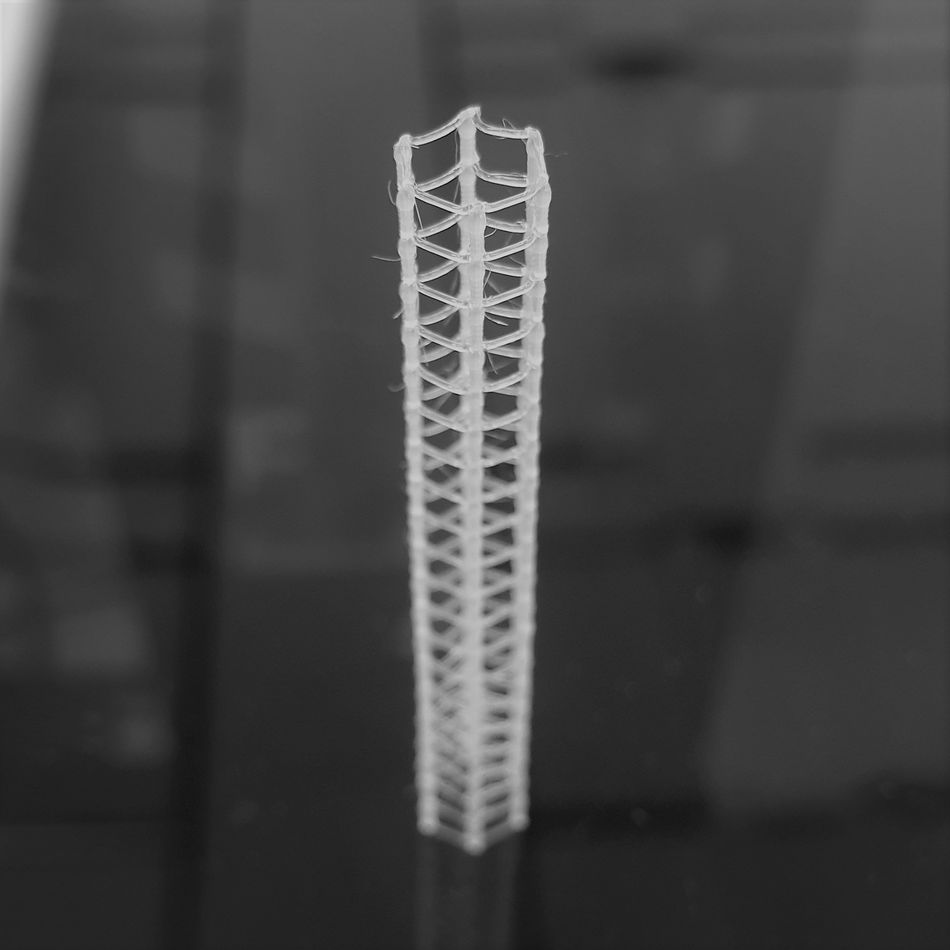

FullControl GCode Designer is applicable for a wide range of designs and applications. It’s been used to print highly controlled simple structures for material characterization as well as complex mathematical forms, in-situ process monitoring, hybrid manufacturing, and production runs >1000. The benefits apply to structures designed and printed at the microscale, such as medical stents, to those at the other end of the spectrum such as large-format polymer and concrete 3D printing. Materials printed with FullControl include thermopolymers, ceramics, silicone, conductive metal inks, biological cell-laden hydrogels, fibre-reinforce polymers and many more materials. Wherever a print path is used, FullControl GCode Designer is relevant because the benefits translate across material systems and size scales.

Major Benefits of the FullControl GCode Designer are

- Quality - the ability to optimize all aspects of the printing procedure to maximize quality, reliability and speed, and overcome any challenges associated with a specific material, printing system or part design.

- Design file efficiency - the design file for the sinusoidal shoe sole concept in the image below requires about 1KB of data, whilst also allowing full parametric adjustment of the size and shape, whereas an STL file (nonparametric) of a similar model may require 1000000 times more data.

- 3D print paths and previously impossible structures – the stent in the image above was printed with continuous vertical extrusion (see the video below)

- Hybrid manufacturing and multi-tool processes – FullControl facilitates the use of multiple tools and auxiliary equipment. Explicit design of tool movement paths eliminates the challenges of tool-part collisions during hybrid manufacturing and allows advanced manufacturing activities such as in-situ process monitoring.

- The software is entirely free and requires no installation. It’s integrated into Excel, which is used as an extremely powerful user interface (enabling Excel’s broad functions to be used in design parameters). No CAD software or software licences are required.

For a detailed demonstration of the design workflow, see the technical introduction video (20 mins)

More information and other tutorials are available at www.fullcontrolgcode.com

CREATE Education would like to thank Andrew Gleadall for taking the time to share his work in research focusing on biomedical polymers and additive manufacturing at Loughborough University.

To learn more about additive manufacturing solutions and how CREATE Education can help and support your University research visit www.createeeducation.com or speak to our specialists at enquries@createeducation.com.