How Zeiss is Using 3D Printed Parts in Serial Production

The renowned technology enterprise Zeiss is at the forefront of the optics industry by using 3D printing to create customized parts for its microscope in serial production. This article explores how this innovative solution has significantly improved the manufacturing process, resulting in substantial time and cost savings for the company.

This article was discussed in our Next Byte podcast.

The full article will continue below.

This article is part of our series on making clear the impact of additive manufacturing on manufacturing. Read the first article about the ways 3D printing enables faster design, less waste, and more customization in manufacturing here.

About Zeiss

Zeiss has global coverage, operating in almost 50 countries, 30 production sites, 60 sales and service companies, and 30 research and development facilities. The company develops and distributes highly innovative solutions for industrial metrology and quality assurance, microscopy solutions for life sciences and materials research, and medical technology solutions for diagnostics and treatment in ophthalmology and microsurgery. In addition, Zeiss is known for its leading lithography optics used by the chip industry to manufacture semiconductor components.

One of Zeiss's subsidiaries, Carl Zeiss Optical Components, is a precision-driven company. It manufactures microscopes, multi-sensoric machines, and optical sensors for industrial measurement and quality assurance.

Organizations worldwide rely on Zeiss machines to produce perfect results, making "reliability" and "repeatability" the company's guiding principles. The machines produced rely on accuracy and precision, down to the hundredth of a millimeter, requiring deep know-how for the assembly process.

Challenges in the production process

Producing high-tech products typically requires customized machines to meet unique process needs. However, this presents a significant challenge for companies. One of the biggest challenges in production is human interaction, which can result in inconsistencies, errors, and losses. Manual adjustments of production machines are another challenge, as they can be time-consuming and require skilled labor, leading to inefficiencies.

Furthermore, as companies shift towards a client-focused approach and product customization, more challenges are imposed on the production processes. Customization requires greater flexibility and adaptability to meet customer demands. However, it may be affected by the supply delays and costs of the traditional production process.

To stay ahead in innovative and technological sectors, companies must be open to incorporating new solutions into their production processes. By embracing new technologies and methodologies, these solutions can lead to greater efficiency, flexibility, and adaptability.

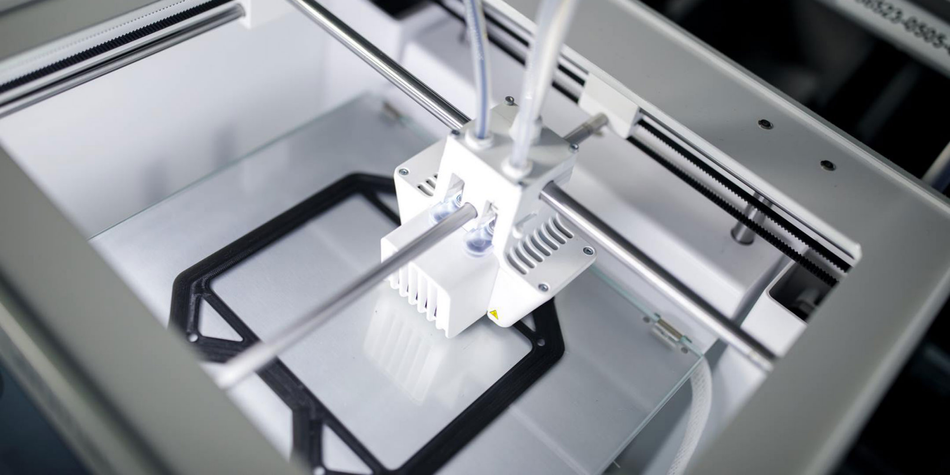

How Zeiss has been using 3D printing

Zeiss has made it a priority to deliver machines with the highest precision and accuracy possible. However, aligning light to optical measurement axes requires brackets and adjustment screws that need to be manually adjusted for each machine. This not only makes the process unstable but also time-consuming. Zeiss has found a better solution using 3D printing technology to address this issue.

The Zeiss team measures the angles of a specific machine and designs an adapter plate that can be 3D printed. This adapter plate ensures that light travels precisely in the right direction and reaches the device's sensor to obtain accurate measurements. Zeiss now 3D prints a unique adapter plate for every microscope in serial production, which further enhances precision and reduces the time required for manual adjustments. This innovative solution has improved the stability and efficiency of the manufacturing process.

3D printing adoption process

Zeiss' digital microscope is an entry-level device for measuring distances or flat components, such as circles. With the adoption of 3D printing, the Zeiss team has recognized the technology's potential to play a practical role in its workflow. Starting with the design and printing of the adapter plate for serial production, the company then expanded the 3D printing application, including jigs and fixtures.

The potential for client-focused projects is also relevant when considering 3D printing use. Using printed prototypes, Zeiss could create customized products using closed-loop and fast-developed iterations to meet customer applications. As the trend of individualization grows, offering tailored solutions to meet each customer's unique needs becomes more relevant. 3D printing enabled Zeiss to quickly and efficiently develop, prototype, iterate, and improve designs rapidly.

Customizing with 3D printing

While Zeiss has shifted away from traditional customized parts, the company continues to utilize customization in the form of adapter plates. Although adapter plates are standardized parts within the product line, each piece is still customized to fit the product's unique specifications, requiring different angles and adjustments.

Johannes Grimm, Manager of Operational Excellence at Zeiss, notes that this approach provides a stable production process and marks the beginning of a trend for customized end-use parts. As the number of different customer needs increases, there is a growing demand for 3D printers capable of handling several materials, including plastics, composites, and metals. This trend presents an opportunity for innovation in the industry, enabling Zeiss to meet the diverse needs of their customers while maintaining a stable and efficient production process.

The new era of parts repositioning

Adopting 3D printing for adapter plates has proven to be a cheaper, more reliable alternative to adjustment screws and brackets and is more customer-friendly. It is also more convenient for customers since Zeiss can produce replacements on demand and send them directly to their location.

Installing the new parts only requires tightening a few screws, eliminating the need for complicated production and mounting processes faced in the past before 3D printing adoption. This has resulted in significant time and cost savings for Zeiss, which is crucial in their competitive industry.

3D printing results

Zeiss has reduced lead times from months to days thanks to 3D printing technology, giving its team members more time to focus on the product design and development process. The ability to iterate quickly with 3D printing ensures that final products are of the highest quality. In addition to time savings, there is a significant cost benefit to using 3D printing. What used to be a €300 process now costs approximately €20 per 3D printed part, resulting in substantial cost savings for Zeiss.

Zeiss selected solution

When Zeiss chose a 3D printing solution, they considered various factors such as ease of use, hardware and software flexibility, and cost. Ultimately, they picked Ultimaker because of its open-filament system, Material Alliance, open-source slicing software Ultimaker Cura, and competitive pricing. Installing an Ultimaker printer in Zeiss' assembly room enabled them to follow their lean production principles and create jigs and fixtures on demand. However, the most critical factor in their decision was Ultimaker's ability to consistently deliver reliable results, which is crucial for maintaining a stable production process and staying competitive.

Leading 3D Printing with UtiliMaker

UltiMaker is a leading company that specializes in creating 3D printers that are both reliable and easy to use. These printers have been carefully designed and rigorously tested to ensure they can run 24/7, giving you the results you need quickly and without hassle. In addition, UltiMaker's software, Cura, is trusted by millions of users and is the world's most popular 3D printing software. Cura software is seamlessly integrated with CAD software and comes with an extensive library of plugins that can be used to customize your print preparation experience.

For businesses looking to expand their production capabilities, UltiMaker offers the Digital Factory. This cloud-based suite of tools allows you to connect your UltiMaker 3D printers and easily upgrade your printing experience. The Digital Factory provides features such as remote print job queuing and unlimited job history. In addition, the Digital Factory includes in-cloud maintenance scheduling to keep you informed about upcoming tasks and maintenance.

UltiMaker's Material Alliance offers the broadest range of materials available today, from advanced polymers to carbon fiber composites. Therefore, you can choose the perfect filament for your application, whatever your needs. Additionally, UltiMaker's global network of service partners provides professional installation, training, and maintenance services in your language and time zone, ensuring that you receive dedicated support no matter where you are.