Tagged with

prototyping

ORGANIZATIONS. SHAPING THE INDUSTRY.

Mitsubishi Chemical Group

Materials Engineering

Mitsubishi Chemical Advanced Materials is a leading global manufacturer of high-performance materials in the form of semi-finished...

31 Posts

InDro Robotics

Robotics and Drones

We empower R&D by providing the computational power, ROS packages, payloads...

14 Posts

WayKen Rapid Manufacturing Limited

Rapid Manufacturing

WayKen is a rapid manufacturer, specializing in rapid prototyping and low v...

4 Posts

Massivit 3D

Large-volume3D printing

Massivit 3D Printing Technologies Ltd. is a leading manufacturer of large-v...

3 Posts

View more

Latest Posts

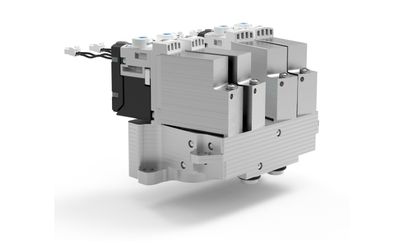

Fast and precise: Parker Hannifin relies on state-of-the-art Online Manufacturing of turned and milled parts

Leading motion and control technology manufacturer benefits from short delivery times, unrestricted capacity and high-quality components

Online manufacturer supplies machined parts for prototypes resulting in significant time and cost savings

Festo relies on parts from Online Manufacturer FACTUREE to develop functional prototypes

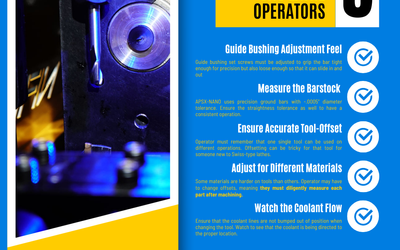

The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC materials available. Furthermore, with the introduction of computer numerical control, the process becomes more accurate, faster, and suitable for making parts with tight tolerance. How much do you know about plastic CNC machining? This article discusses the materials compatible with the process, available techniques, and other things that can help your project.

In this article, we will delve into the diverse world of CNC materials. We will provide you with a comprehensive guide to selecting the right materials for CNC machining, including a detailed list of commonly used materials. Additionally, we will touch on some lesser-known materials that you may not have considered before.

This blog comprises a collection of articles on innovation written by Hubert Martens, the CEO and founder of Salvia BioElectronics. Originally shared on LinkedIn, Martens intended to spark a conversation about innovation and introduce the innovation model he and his team developed over their careers.