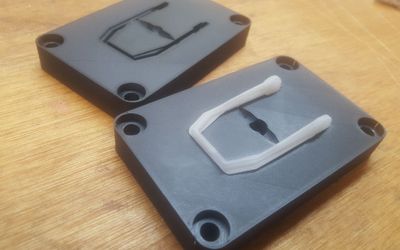

Injection molding is an invaluable process for creating plastic parts. This process is fast, cheap, and helps create vast volumes of identical objects. One of the most significant advantages of injection molding is the natural surface finish of molded parts. Even without any injection molding surface finish or post-processing treatment, molded parts have smooth surface finishes suitable for many end uses.

Tagged with

product design

ORGANIZATIONS. SHAPING THE INDUSTRY.

Xometry Europe

On-Demand Manufacturing

From instant quotes to expert insights—Xometry powers smarter manufacturing...

23 Posts

View more

Latest Posts

The renowned technology enterprise Zeiss is at the forefront of the optics industry by using 3D printing to create customized parts for its microscope in serial production. This article explores how this innovative solution has significantly improved the manufacturing process, resulting in substantial time and cost savings for the company.

The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC materials available. Furthermore, with the introduction of computer numerical control, the process becomes more accurate, faster, and suitable for making parts with tight tolerance. How much do you know about plastic CNC machining? This article discusses the materials compatible with the process, available techniques, and other things that can help your project.

Online Manufacturer supports assembly work at the world's largest stellarator fusion reactor with CNC-machined special parts

FACTUREE supplies components for fusion research facility at the Max Planck Institute for Plasma Physics

In this article, we will delve into the diverse world of CNC materials. We will provide you with a comprehensive guide to selecting the right materials for CNC machining, including a detailed list of commonly used materials. Additionally, we will touch on some lesser-known materials that you may not have considered before.

This blog comprises a collection of articles on innovation written by Hubert Martens, the CEO and founder of Salvia BioElectronics. Originally shared on LinkedIn, Martens intended to spark a conversation about innovation and introduce the innovation model he and his team developed over their careers.