Tagged with

Printed Electronics

ORGANIZATIONS. SHAPING THE INDUSTRY.

Latest Posts

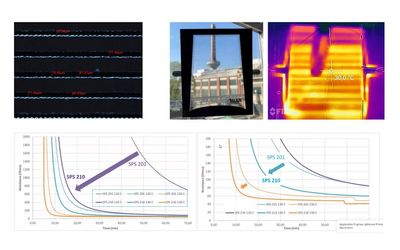

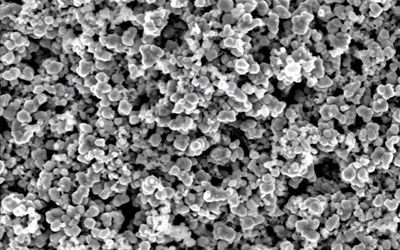

Silver nanoparticle inks improve every year. These improvements are often incremental, but very important. One ever-present direction of development is towards inks which offer ever higher conductivity levels at a low curing temperature and a short curing time. This a critical figure of merit because it opens more substrate choices, saves time, and lowers energy consumption costs.

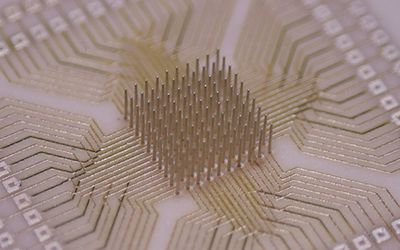

Experimenting in the world of Flexible Hybrid Electronics (FHE) comes with a variety of hurdles. Printing technologies are vastly different in terms of materials compatibility and have pros and cons that make them suitable for particular applications. Choosing materials that match the printing technology you intend to use is the most important decision you’re going to make. But what if one could print, digitally, using any paste and ink on any substrate? Read more

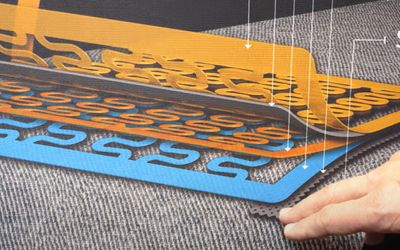

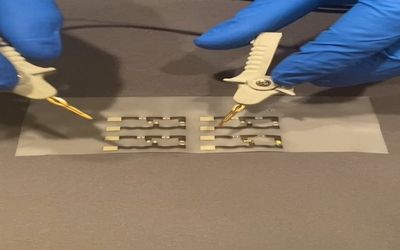

Wearable electronic textiles are a demanding environment for reliable interconnects – the ability to function with movement and survive multiple cleanings and reuse. Good adhesion is particularly challenging in these wearable and conformable electronics applications. While solders provide the most conductive electrical connection, they are rigid and require not only the addition of an underfill adhesive but usually a post bond encapsulation. This Anisotropic Conductive Epoxy, provides reliable interconnections between electronic components and circuitry on textiles with excellent structural bonding, without encapsulation, even under repeated stretching and washings. This technology has been shown as a scalable assembly process for e-Textile manufacturing in an SMT line.

Will copper nanoparticle inks finally come of age to disrupt the dominance of silver in the conductive paste business?

Cost of production has been a major barrier despite the fact that Cu raw material prices are far lower than Ag. This is because this large raw material cost difference does not often get translated into equally large nanoparticle dispersion or ink costs. Can this be overcome?