Tagged with

digital manufacturing

ORGANIZATIONS. SHAPING THE INDUSTRY.

View more

Latest Posts

Online Manufacturing of special parts adds benefits for textile manufacturers such as quick availability

Freudenberg Performance Materials, a leading global developer and manufacturer of innovative technical textiles, explores new paths with its procurement of components. In this endeavor, the company has chosen FACTUREE – The Online Manufacturer as its supplier for various parts.

Computer Numeric Control (CNC) Machining is one of the most popular manufacturing techniques that use automated tools to generate the needed shapes and parts. What is CNC machining or how it works is a common question that anyone associated with the industry should know about. The following text will take a look at the basics of CNC machining and briefly discuss its major applications across different industries.

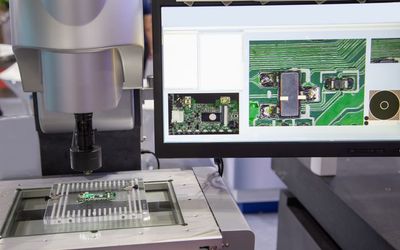

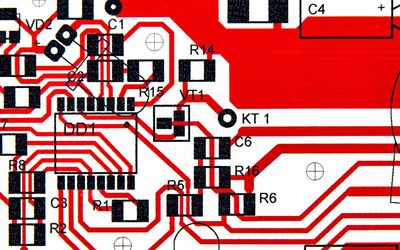

First article inspection (FAI) is a crucial step in the manufacturing process. The quality control (QC) team needs to optimize this phase of inspection in order to limit the back and forth between conception and fabrication. The QC team must not only correctly identify the defects, but also provide relevant data, measurements, and results for solving the identified problems.