Tagged with

3D Printing

ORGANIZATIONS. SHAPING THE INDUSTRY.

The Next Byte

Entertainment

The Next Byte Podcast is hosted by two young engineers - Daniel and Farbod - who select the most interesting tech/engineering cont...

165 Posts

View more

Latest Posts

From solar cells to endless applications across industries: inkjet printing revolution enabled by Electroforming technology

Progress in printhead technologies, material science, and manufacturing processes has markedly enhanced the capabilities of inkjet printers. Inkjet printing has now discovered applications in an expanding variety of industries and processes.

While industries like aerospace and automotive have been using additive manufacturing technologies for many years, the marine sector has recently picked up the pace of adoption thanks to the benefits provided by Large Format Additive Manufacturing. Companies like yacht and ship-builders are quickly speeding up the introduction of large parts manufactured with technologies like Caracol's Heron AM.

The military and defense sectors are undergoing an unprecedented transformation as military bases around the world adopt 3D scanning and additive manufacturing technologies for a wide range of applications. That includes maintenance, repair, and overhaul (MRO) processes, damage assessments and reverse engineering of parts, to name a few.

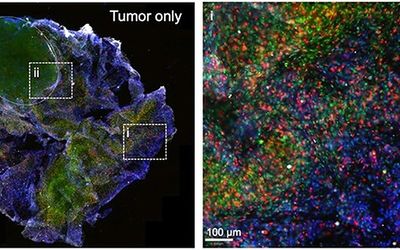

Researchers have developed a 3D bioprinter for cancer research that can be folded into a carry-on pack, transported, and easily reassembled for printing inside a biosafety cabinet. The technology can perform rapid and reproducible manufacture of complex tumouroids – 3D cell cultures which resemble tumour tissues – to test potential immunotherapy treatments.

In this episode we talk about how researchers at EPFL have developed a new method of 3D printing bone-like composites using bacteria-infused ink. The process involves the use of hydrogel as a printing medium that provides a scaffold for bacterial growth, which produces calcium carbonate crystals that mimic the properties of bone.

The beauty of additive manufacturing is in the flexibility these technologies provide in terms of scale, shape, and materials. Building know-how on software has allowed Caracol to leverage these skills and adapt them to working with robotics for LFAM on different processes - from its proprietary thermoplastic/composite pellet extrusion Heron AM to introducing Metal with WAAM.