Prototyping in Additive Manufacturing

How Do You Manage Your AM Prototyping Efforts - Is Engineering or Delivery Time More Important to Satisfy Customers?

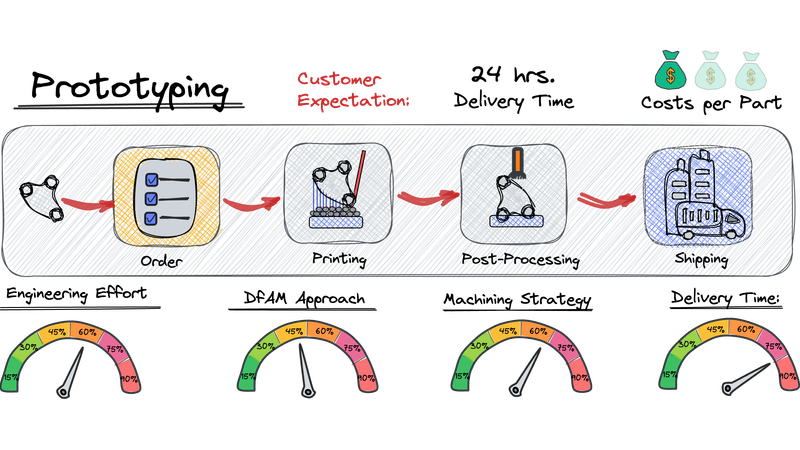

AM Process Chain - Focus on Prototyping

Overview

In the past, additive manufacturing (AM) was most likely used for prototyping. Quickly and with minimal effort, a component was made available to the customer. At the same time, manufacturing should require as little post-processing as possible to meet short delivery times. Is AM prototyping really as easy as the comment above suggests? Let's focus on some of the challenges you will face in preparing your part for AM prototyping and start get a better understanding.

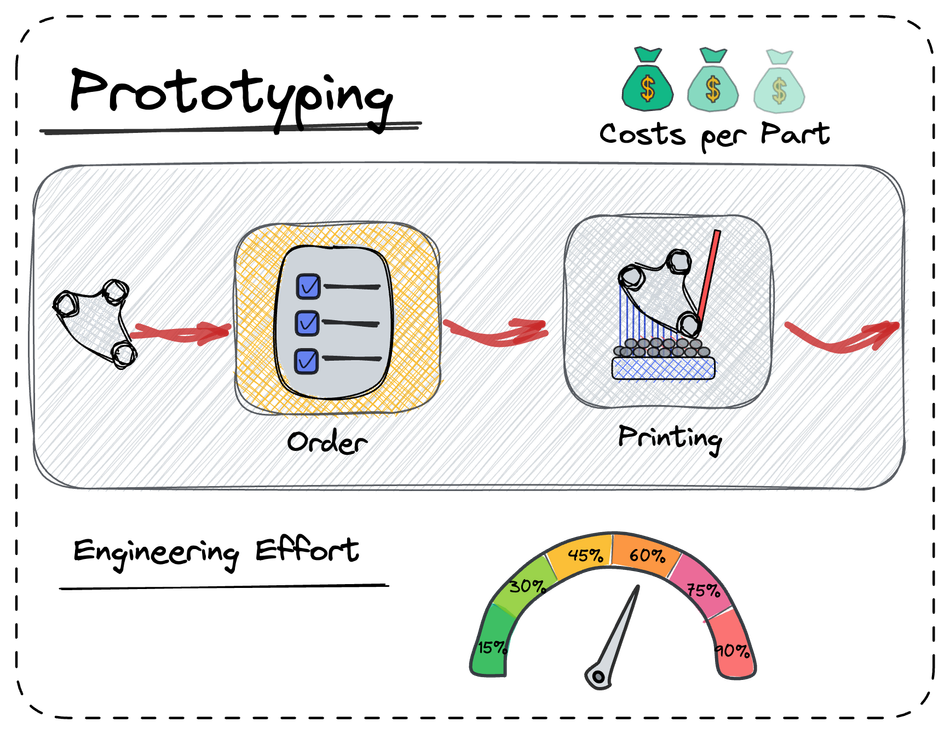

Engineering

Time is probably one of the most common problems in prototyping. The customer needs a part as soon as possible, whether for use in a new product line, as the basis for a simulation, to present an idea to management, or to motivate an upcoming series. Engineering time should be kept to a minimum because short lead times mean there is no time for engineering, which would increase the cost per part anyway. Getting print jobs right the first time takes on a whole new meaning.

In reality, however, time must be invested to achieve good part quality, especially for prototypes. In order to produce an OK part as quickly as possible, standards are created in process preparation. These standards are created in process preparation to produce a part as quickly as possible without having it evaluated by process engineering. However, it takes time and experience to establish these standards and develop a good manufacturing parameter that is not only product specific.

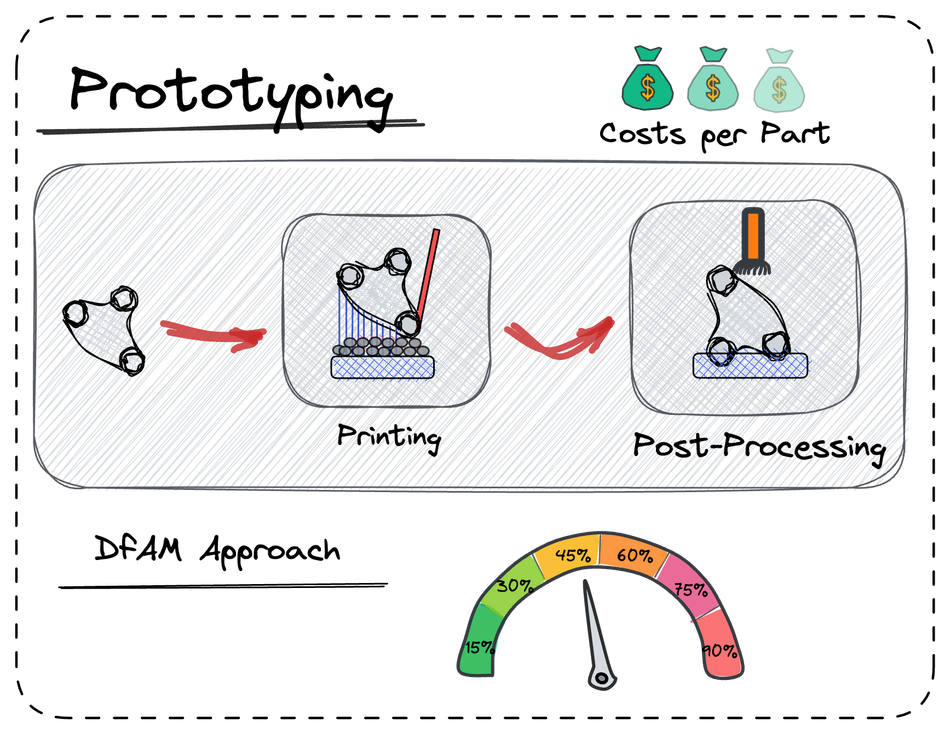

Design for Additive Manufacturing (DfAM)

Because parts are often not optimized for additive manufacturing, the risk of process failure also increases. Design for Additive Manufacturing (DfAM) is already being used much more than it was a decade ago. However, parts still have a high level of support structures that need to be completely removed afterwards to achieve good quality. This does not always make it easy for process preparation to optimally orient the components and nest as many components as possible on the platform.

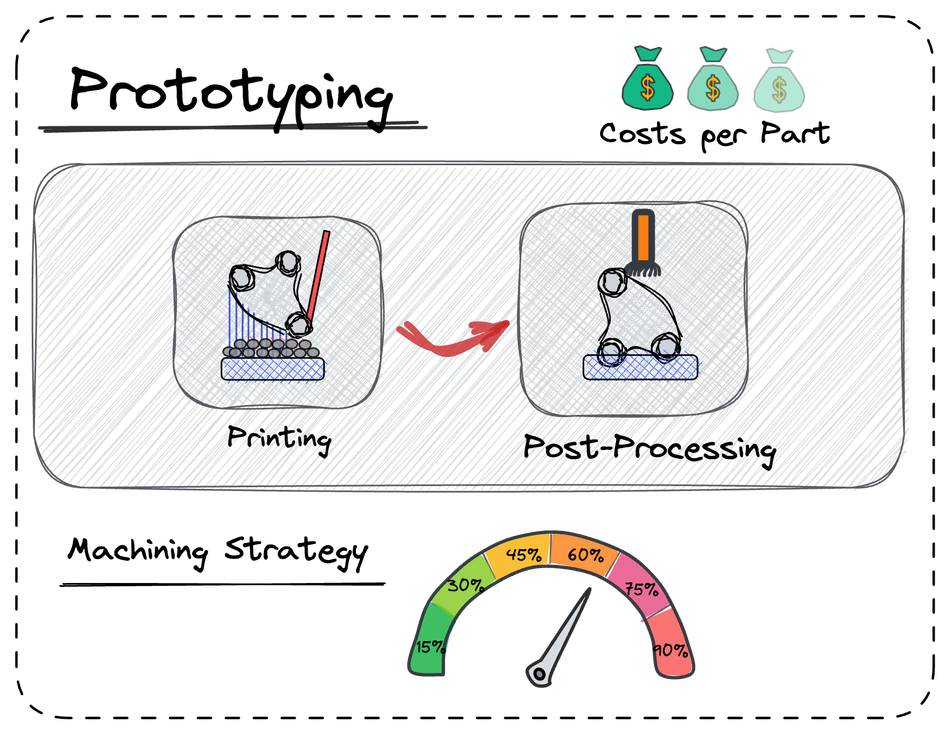

Machining Strategy

Post-processing of the parts requires a high degree of creativity. Parts receive different finishes after printing. Functional surfaces are usually reworked so that the components can be installed. This requires a high degree of creativity because additive parts tend to warp and their complexity makes it difficult to create a reference for post-processing. In most cases, post-processing is considered a "no-brainer," but it is another major skill in the AM process chain that is often underestimated.

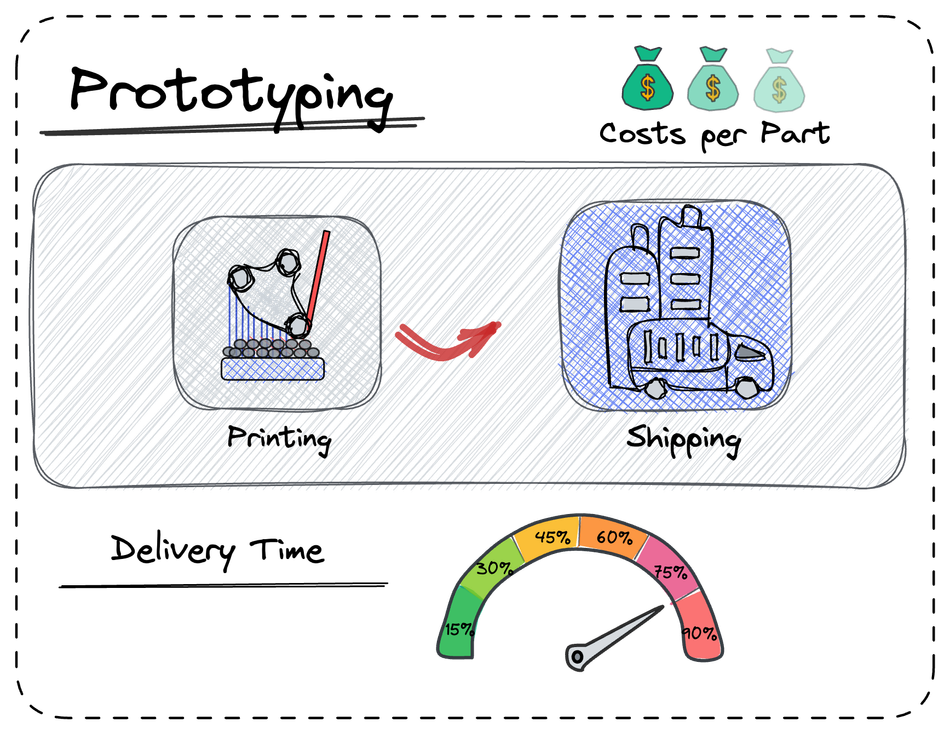

Delivery Time

Finally, the components are shipped to the customer. The production status of the components and the documents must be correct so that no time is lost in the downstream "simple" processes. This requires digital systems and component monitoring throughout the process chain. Sounds simple, but can be time consuming.

Conclusion

In summary, I believe that prototyping is essential to the AM industry. It will continue to be demanded by customers, even though many companies are looking towards volume production and prefer established processes with developed support and process parameters. The technical requirements for prototyping allow for rapid adoption of AM processes. Therefore, it will continue to be used in the future as the focus increases on AM volume products that require a prototype upfront.

What is your experience on AM Prototyping? Do you use AM manufacturing processes frequently in your daily business?

Looking forward to your opinion!

Sebastian

You would like to understand the potential of Additive Manufacturing (AM)?

First, you need to get a general understanding of Design for Additive (DfAM); Features to Identify new AM Applications and Process Capabilities; as well as an overview of possible Post-Processing Strategies. These topics will help you to identify a differentiator that would increase an "AM-Only Advantage".

That's why I decided to publish a blog for education of young engineers!

www.understanding-additive.com

You are welcome to stop by and join!