Trends in 3D Printing

Four trends are setting the scene for 3D printing to become ever more versatile and deliver products that are closer to end-use, production level

Image by Andrew Cameron at Noun Project

This article was first published on

www.xometry.comWhat lies ahead for 3D Printing

3D printing (additive manufacturing) technologies have continued to evolve, adapt, and reinvent themselves. 3D printing has become commonplace with the added demand from engineers and consumers alike. The production of additive manufactured parts is commonplace at Xometry and nests nicely with piece-parts for prototyping or one-offs. 3D printing bureaus must keep an eye on the future of 3D printing. Below are some of the hottest trends in 3D printing that will help elevate the manufacturing industry.

You can also download the full eBook version of this article here.

Trend 1: Additive Process Control Software is On the Rise

Most application-specific additive manufacturing technologies require a comprehensive build setup to ensure the part completes the printing process and can undergo post-processing. As most operators know, this is sometimes easier said than done. Stresses introduced to parts during building can sometimes cause peeling, warping, or even cracks that result in a failed build. In order to close the gap between the expectations and reality of industrial 3D printing, the process must become more reliable end-to-end.

Virtual machines

These are being used to optimize build orientations, organically generate support, and even pre-deform parts to compensate for built-in stresses during processing. By simulating a part’s custom shape, how it is supported, and the conditions in which it is built, novel software like virtual machines have been able to drive better outcomes with little to no additional iterations. This process can significantly reduce a process called “part characterization” where designs and machines are tuned to generate consistent and predictable results. Without software, part characterization can often take weeks to months depending on the application with significant non-renewable engineering investment.

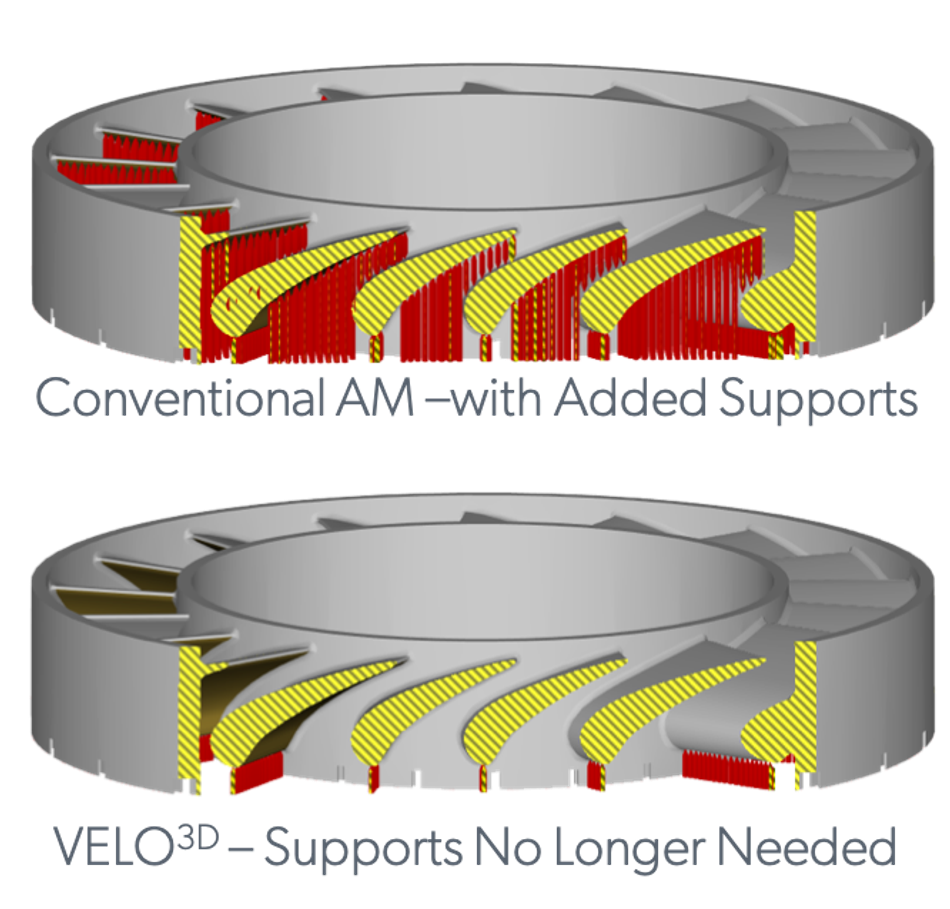

Companies like Velo3D have been able to reinvent the metal laser sintering platform by incorporating software that predicts and mitigates overhangs. Velo3D’s additive manufacturing solution can make metal parts with much less support, or even with no support structure at all, flipping traditional DMLS paradigms upside down.

In-situ monitoring

A process called in-situ monitoring is now built in to many high-performance platforms. Originally, it allowed manufacturers to see snapshots of their layers as they were built so they could identify potential issues that may not be visible in the final part. Products like Sigma Labs PrintRite3D ® combine software and hardware for monitoring 3D metal prints as they are built. This is significant if a 3D print is for aerospace or automotive applications, where a small defect could have huge liability. Some 3D printing platforms can even use take in-situ monitoring to the next step by steering corrective actions during the print if the monitored layer was not behaving as predicted. This reduces scrap and increases part quality.

In-situ monitoring has transformed HP’s Multi Jet Fusion’s technology by not only providing print feedback, but also by providing data-driven improvements and parameter upgrades across the entire printer product line. This means that the more parts that are built on the HP platform, the better all platforms will get at building parts through automatic feedback systems.

Trend 2: Increased Isotropic Print Possibilities

Process control will help make future printers and 3D printed solutions more predictable and measurable. But what about the process itself? 3D printing historically has been difficult to simulate via finite element analysis (FEA) because of direction-dependent properties. This can lead to good design intentions with low performing outcomes. Vertical feature strength is often not directly tied to the material, but instead, to the strength of the bond between layers in a 3D print.

When there is a significant difference in directional strength, the part is called anisotropic. Injection-molded, cast, and machined parts all exhibit isotropic properties, where the strength of the part is direction agnostic. Luckily, 3D printing is increasingly becoming isotropic, and therefore, structurally comparable to traditional manufacturing processes.

Continuous 3D printing, like Carbon DLS™, is one method of producing parts with isotropic features. If you think of each 3D printed layer as a “slice,” where each is fused to the previous, you might think of continuous 3D printing like a video, moving in tandem with a progressive Z-direction movement. Because there is no start, stop, move, and repeat motion, the traditional consequence of different properties existing in the vertical no longer comes into play. This does not mean that Carbon DLS parts do not have layers, since there still is subdued visible stepping inherent in the translation from model to the projector. However, the continuous movement ensures the curing does not cause inconsistent properties.

Novel fusion on filament-based systems like fused deposition modeling (FDM) and fused filament fabrication (FFF) can also produce isotropic properties. This can happen by using a jetted material between layers or even manipulating material properties to influence fusion. RIZE ™ has 3D printers that deposit specially formulated agents between layers. These agents can either enhance the layer bond or promote release for features like a support structure. Fortify has built a printer that uses a composite in its materials that can be manipulated in the melt state. This process, called Fluxprint, uses a magnet to directionally align small fibers as the layers are melted and fused, creating custom mechanical properties and greatly reinforcing Z-adhesion. Essentium has its flashfuse filament technology which electrically welds layers to produce significantly higher Z-strength.

3D contouring is another option for filament-based 3D printing, and was demonstrated recently by researchers at the University of Hamburg. This method deviates from the typical method of making a stack of 2D flat layers to build a model and instead, builds non-planar layers without a defined vertical direction. This allows mechanical features to retain their strength regardless of direction. In metal 3D printing processes, such as directed energy deposition (DED), the build substrate is typically held on a moving platform, allowing the material to be deposited in freeform. BeAM, a producer of DED equipment, has highlighted DED as a way to deposit materials for part repair as well as producing near-net-shape parts from scratch.

Innovations in 3D printing technologies such as continuous 3D printing, novel fusion on filament-based systems, and 3D contouring have opened up the possibility of isotropic parts to bring greater structural strength to parts.

Trend 3: Novel Materials and Processes

In addition to software-driven build simulation and feedback and novel ways to add isotropic strength to a part in the previous section, innovation in 3D printing is being moved forward by new materials. These are not just more thermoplastics or photopolymers, but new material families that further bridge gaps between prototype and end-use production without traditional manufacturing methods.

Compounds, or reaction polymers, are starting to make an appearance in liquid-based 3D printing platforms. Examples of these materials are two-part resins like urethanes and epoxies, which are mixed before curing. Reaction polymers can exhibit significant strength, durability, and longevity over materials that are only photopolymerized. Carbon’s Digital Light Synthesis ™ (DLS) uses reaction polymers that are cured via UV projection and then post-thermal baked to activate the compounds. Combined with continuous 3D printing, this allows DLS parts to exhibit strength more similar to injection molded or urethane cast products than standard 3D prints. The company Origin has also been developing multi-stage materials (named thermo polymers) for UV printers using stereolithography (SLA) or digital light projection (DLP) platforms.

Ceramics have high heat resistance properties (typically over 1200C), which allows them to be used when metal 3D printing materials are not sufficient. The promise of ceramic 3D printing is not in flower pots or vases, but in precision high-heat applications for aerospace, automotive, and medical industries such as housings and rocket nozzle inserts. While ceramics are difficult to precision form due to being highly stiff and brittle, special grinding and shaping equipment is used and often custom designed for the workpieces. Plate-shaped ablatives, used on space re-entry vehicles, could also be powerfully augmented by eliminating manufacturing constraints using printed ceramics.

3D printing with ceramics usually is based on an adaptation of SLA, where a UV laser cures cross sections of a material embedded with ceramic. 3D Ceram’s process comprises multiple stages, starting with an SLA-like process. The printed parts are in a green state, meaning they are too fragile to handle. The green parts are then baked in a kiln, which causes all non-ceramic materials to burn out, leaving only the final material behind in a shrunken state. In the future, this process could also be applied to for carbons, graphites, and other stabilized high-heat materials.

Carbon DLS has expanded the possibilities of rubber-like parts retaining both durability and elasticity with elastomeric polyurethane (EPU) and urethane silicone (SIL) materials. These are compounded, printed, then cured for end-use properties. Additionally, thermoplastic urethanes like TPU and TPE have shown promise of demonstrating these physical properties using fused deposition modeling (FDM) as well as powder bed fusion processes like selective laser sintering (SLS) and HP Multi Jet Fusion (MJF). However, they often do not fulfill surface finish requirements to go beyond prototyping.

2020 may be the year of true silicones, offering not only flexibility, but also the biocompatibility, transparency, and high-heat resistance that you may be familiar with for many household products. Room-temperature vulcanized (RTV) silicones can be printed with extrusion-based platforms like ACEO’s product line, or may even be suspended without support structures like Picsima’s platform. There is a lot of innovation in the 3D printed elastomer space so keep your eyes peeled!

Metal binder jetting and metal deposition are novel materials that are making a comeback. Binder jet and plasticized metal processes have been around for decades; these processes stick material together in a green-state shape, and then typically go through post-processing to create a functional part. Why is this news? Because these processes have a high potential of disrupting the current metal 3D printing market, as metal binder jetting and metal deposition green parts are typically cheaper and require less ventilation and handling precautions during printing.

Post-furnace finishing also has the promise of creating isotropic part features and self-correction in metal crystallization or voids. The key players in this space are ExOne, Desktop Metal, HP, and Markforged. Each one of these companies offers direct binder jet solutions and work cell options. Markforged and Desktop Metal also offer a machine that behaves similar to fused deposition modeling, where a rod of plasticized metal is extruded in a planar pattern, growing the green-state part from bottom to the top. All these processes are able to draw on lessons learned from metal injection molding (MIM), which has been used to mass-produce small, detailed metal components with characteristics like metal stock.

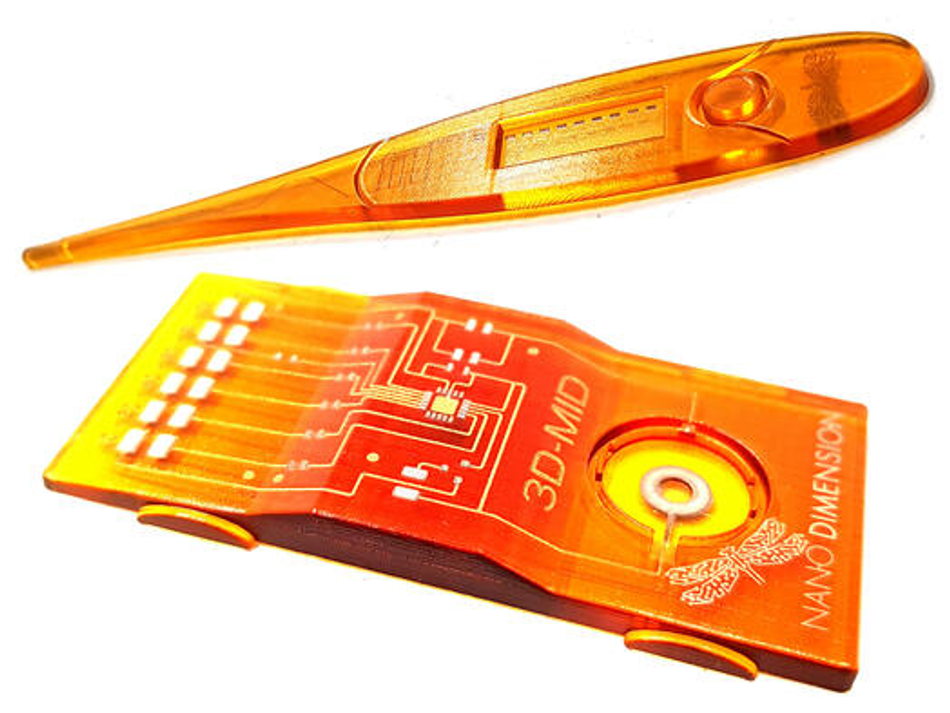

3D printed circuit boards have been making waves in additive manufacturing since the introduction of Nano Dimension’s Dragonfly platform. Conceptually, the process is similar to PolyJet, where multiple materials can be deposited in the same print. In a dual-material print, one of the materials can have similar properties to a circuit board while the other can acts as a conductive layer called a “trace.”

With IoT and the proliferation of electronics, the need for printed circuit boards (PCBs) has never been more relevant. Building PCBs is relatively established in the industry, but it does have its own design constraints because inherently, PCBs are layered. Conductive traces typically require a feature called a “via” to continue between layers, and components are almost always on the top or bottom. 3D printing circuit boards opens up opportunities to embed electronics by design, route traces in 3D (including trace diameter), and build more conformal features to optimize RF signal, antennas, or just keep the design compact. By blending the concept of the board and housing, 3D printed circuits can deliver new approaches to electromechanical design.

Surface finishes have always been an obstacle for end-use additive manufactured components. For processes like FDM, HP MJF, and SLS, there is a tradeoff between robust mechanical properties and coarse surfaces. Even with processes like metal 3D printing, there is often a need for significant manual or vibratory finishing to make the part smooth.

Recommended reading: Surface Roughness In 3D Printing

2019 introduced solutions other than vibratory finishing, such as the PostPro3D platform, launched by Additive Manufacturing Technologies (AMT), which can smooth and tint many 3D printed polymers in an automated, repeatable manner. Dyemansion, best known for its automated SLS dyeing machine, has also added surface finishing technologies to their lineup.

For metals, traditional finishing such as media tumbling could smooth out external features but often removes edge detail on the part. This is because tumbling abrades and removes surface. Novel processes like DLyte’s dry electropolishing uses alternating charges between anodes and cathodes in an electrolytic media base to homogeneously even out the material surface while retaining feature detail. By reducing acute stress junction on the part surface, 3D prints can achieve smooth surfaces on 3D prints to meet both cosmetic and strength requirements.

Trend 4: Viable Hybrid 3D Printing Technologies

The final trend for 3D printing in 2020 is the hybridization of technologies due to advancements in software, hardware, and material science. While CNC machining, urethane casting, injection molding, and other established production technologies still have many advantages over 3D printing, these can be combined with additive manufacturing to enhance surface smoothness, low tolerances, and material types in industrial applications. It is time to shift the thinking from how 3D printing competes with traditional manufacturing to how 3D printing complements traditional manufacturing. As the saying goes, “If you can’t beat them, join them.”

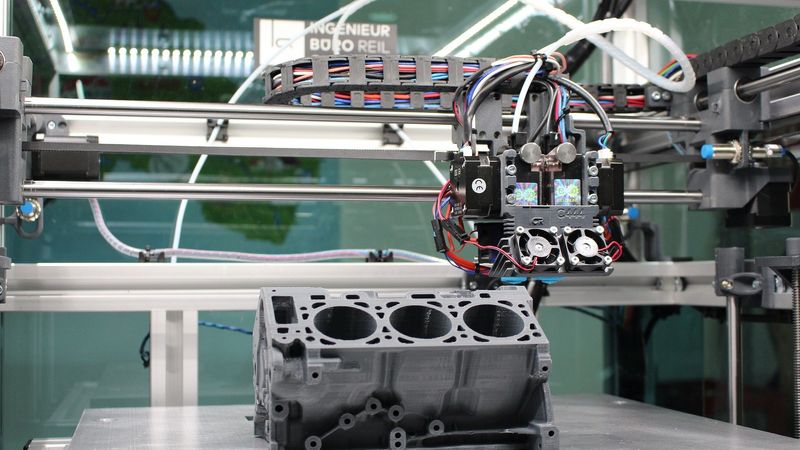

CNC machines with integrated 3D printers, or the other way around, have been in development for the last decade. Although these machines show promising results, 2020 will show much greater maturity with a combination of equipment and the appropriate supporting software. Mazak’s INTEGREX series has an additive manufacturing head which can deposit metal in a fashion similar to directed energy deposition (DED). The material deposited hits a near-net shape of the final feature and is completed with CNC tooling. An example of a Mazak CNC machine with a 3D printing feature is the Matsuura LUMEX series. This machine uses a process similar to DMLS, where parts a laser fuses metal powder in an inert chamber layer-by-layer and a high-speed machine tool head activates in between layers to post machine. This results in parts that look machined but can have a level of detail comparable to that of EDM machining, all without major post-processing.

3D printing composites combine traditional tooling with 3D printing, and this process has gained momentum leading into 2020 particularly with Markforged’s desktop printer. Building composite parts typically enhances part stiffness and mechanical properties by incorporating materials like carbon fiber into otherwise flexible polymers. This is a play on traditional fiberglass layups, where fiberglass or carbon fiber sheet is cured with epoxy against a shaping tool. Because the fibers are inherently stiff, the formed geometry blends high performance with lighter weight.

Markforged’s printers incorporate layers of continuous fiber in selected layers of the part, providing significant stiffness in the XY direction. Other companies, like Continuous Composites, go a step further by having a continuous fiber across the entire print held in place by a thermoset material. Blending more traditionally sheet layup approaches with 3D printing methodology, Impossible Objects prints sections of the part on sheets and then post-compresses to cure into a net-shape part.

Innovations in 3D printed tooling will help bridge the gaps between traditional approaches for manufacturing and rapid prototyping. Beyond building a mold cavity or insert, 3D printed components can have specific features that enhance mold performance. Conformal cooling is the most relevant example of how metal 3D printing can add utility to traditional mold making, and with hybrid approaches stated above, there is even more opportunity for plug-and-play tooling operations.

ColliderTech, has approached 3D printed tooling with a process to print a cavity for compounded resins like urethanes and epoxies. ColliderTech prints the cavity with features that aid material injection and curing. This results is a casted part without the need to build a silicone or rigid tool. Because much of the expense in urethane casting and RTV molding is the tool cost, this process could significantly decrease entry prices for high-performance components.

Conclusion

When a single additive manufacturing part can be produced to the same quality as the final production parts, 3D printing will have reached the peak of its development. This will steadily increase in possibility through machine innovation, novel materials, hybrid approaches, and advancements in software.

In 2020, many technologies that have been in development will start to become more widely available. Current offerings continue to mature and expand in materials, finishes, and quality. Excitingly, 3D printing have become common in both prototyping and production, and it now stands alongside giants like machining and molding. Those who want to try to augment their manufacturing in 3D printing have the benefit of utilizing multiple technologies, getting instant pricing online, and accessing the design resources through manufacturers like Xometry.